Modular efficient heat exchange structure

A heat exchange structure and modular technology, applied in the field of heat exchange, can solve the problems of increasing the consumption of manpower and material resources and the inability of the radiator to meet the heat exchange, and achieve the effect of reducing the consumption of manpower and material resources, saving equipment manufacturing materials, and reducing economic losses.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

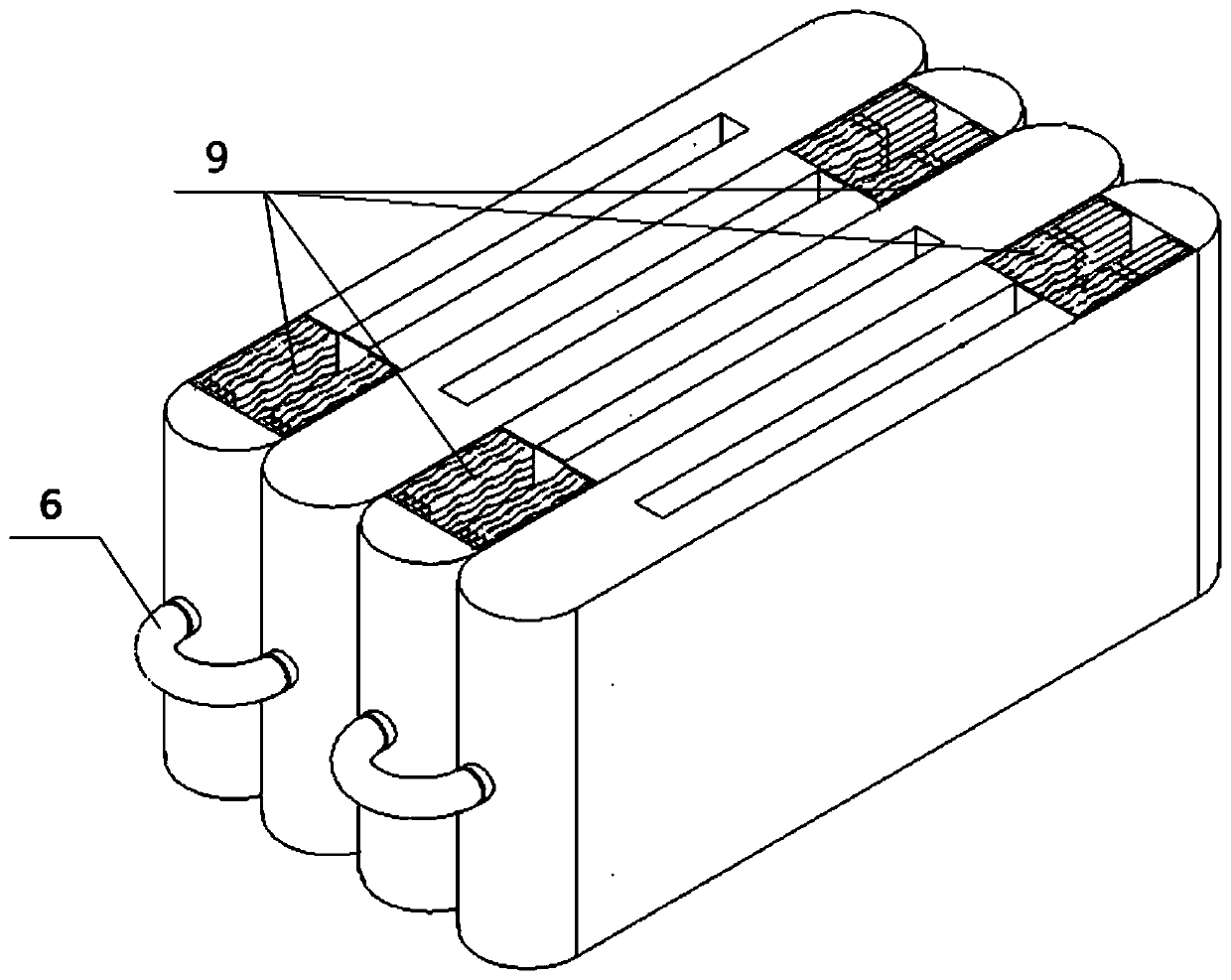

[0019] Such as figure 1 and figure 2 As shown, the three-dimensional variable space high-efficiency radiator disclosed by the present invention includes four groups of radiator modules, and connecting elbows 6 are installed between adjacent radiator modules.

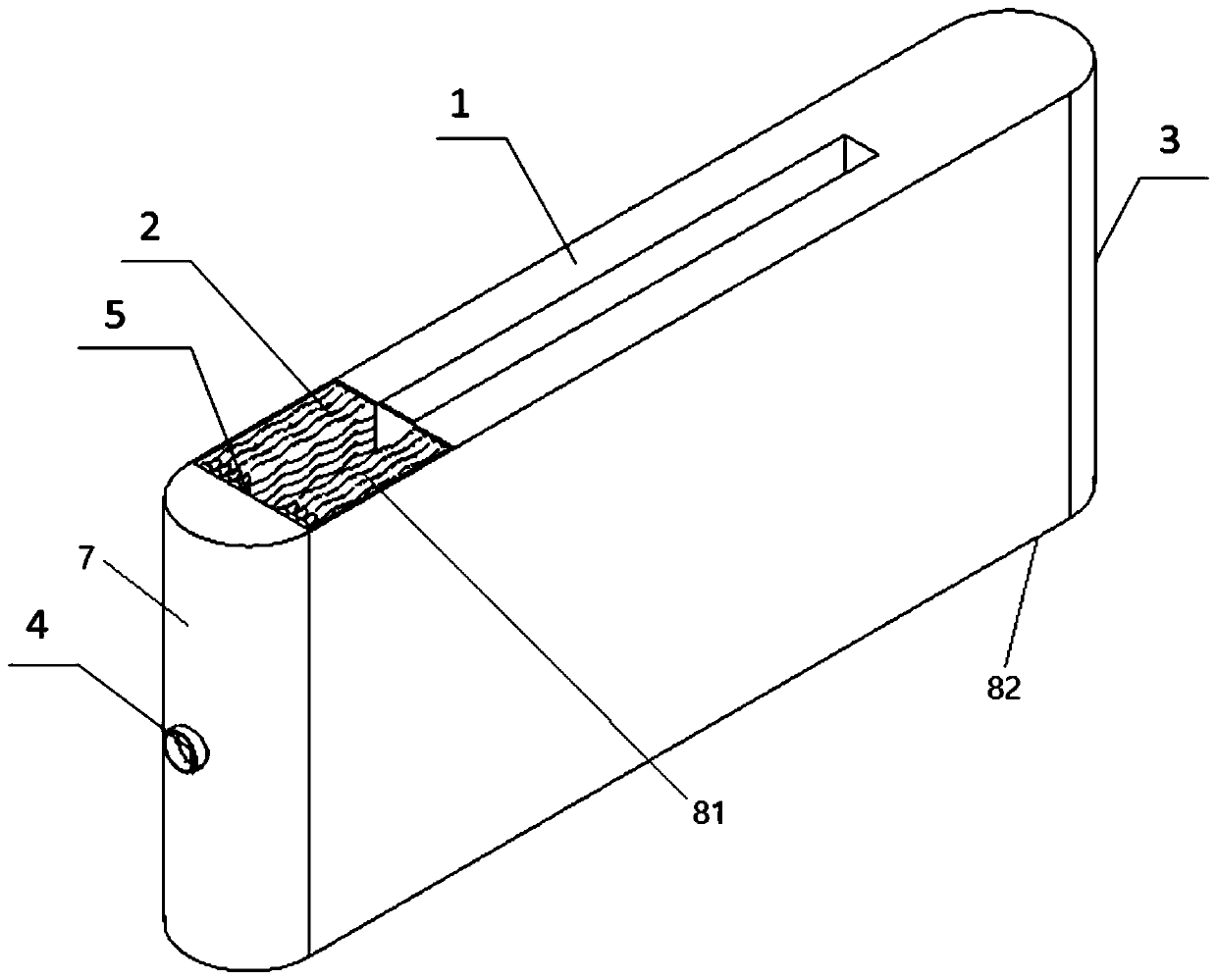

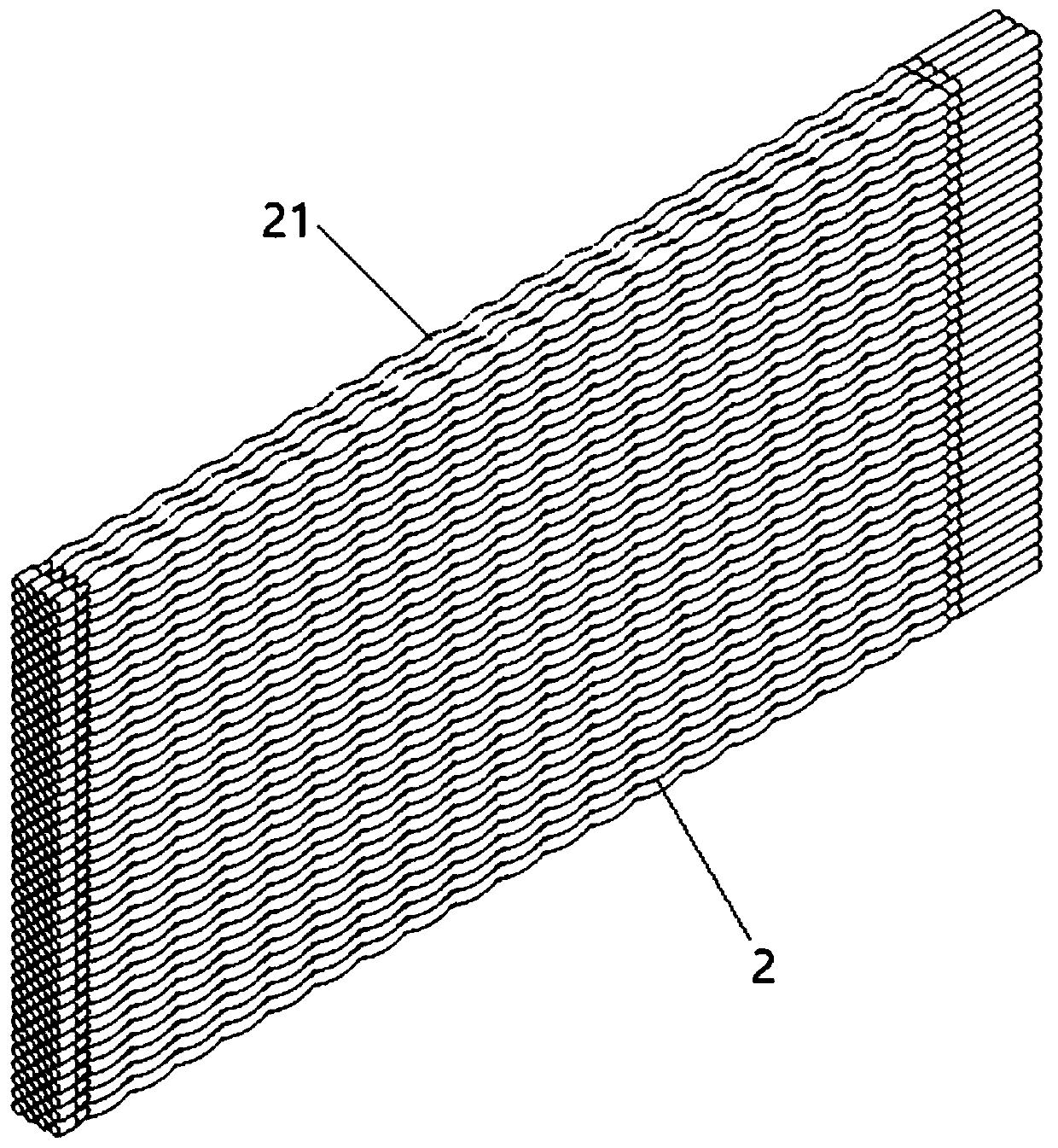

[0020] Such as figure 2 and image 3 As shown, the radiator module includes two groups of tube bundles 2, and the tube bundle 2 includes several three-dimensional deformed tubes 21 arranged side by side, the middle parts of several three-dimensional deformed tubes 21 are arranged as twisted oval tube structures, and the two ends of several three-dimensional deformed tubes 21 are arranged as Round tube structure, the tube bundle 2 is in the shape of a rectangular block, the two ends of the two sets of tube bundles 2 are provided with hollow end caps 7, the shape of the end caps 7 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com