Automatic carton stacking equipment and using method thereof

A carton, automatic technology, applied in the stacking of objects, de-stacking of objects, conveyors, etc., can solve the problems of bumps in the handling process, low work efficiency, product damage, etc., to release labor, simple structure, Ease of proofreading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

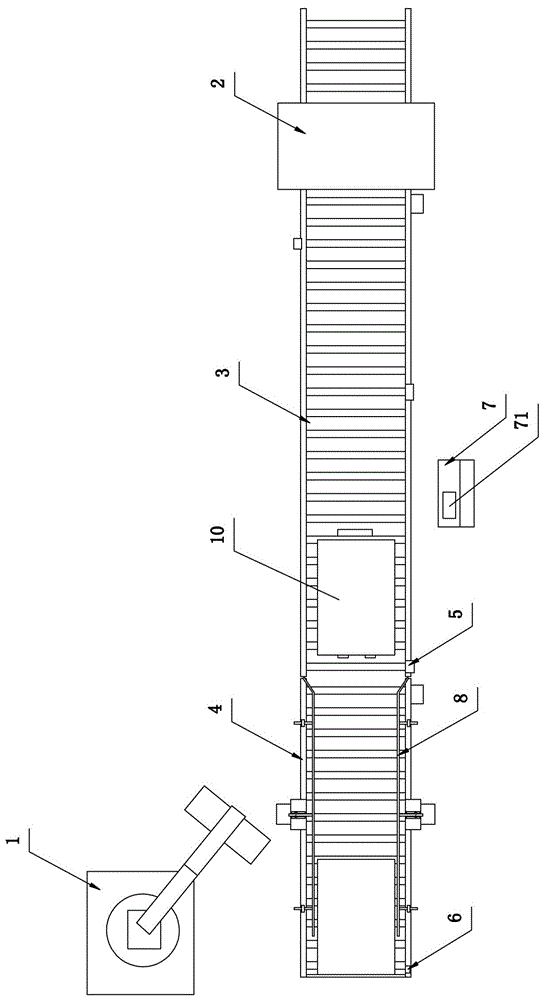

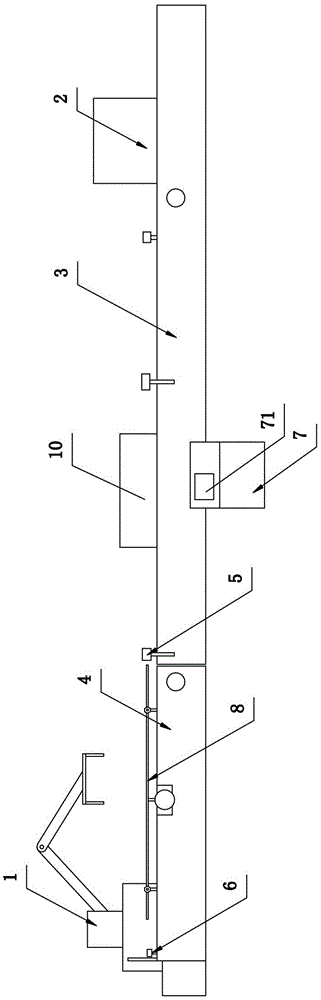

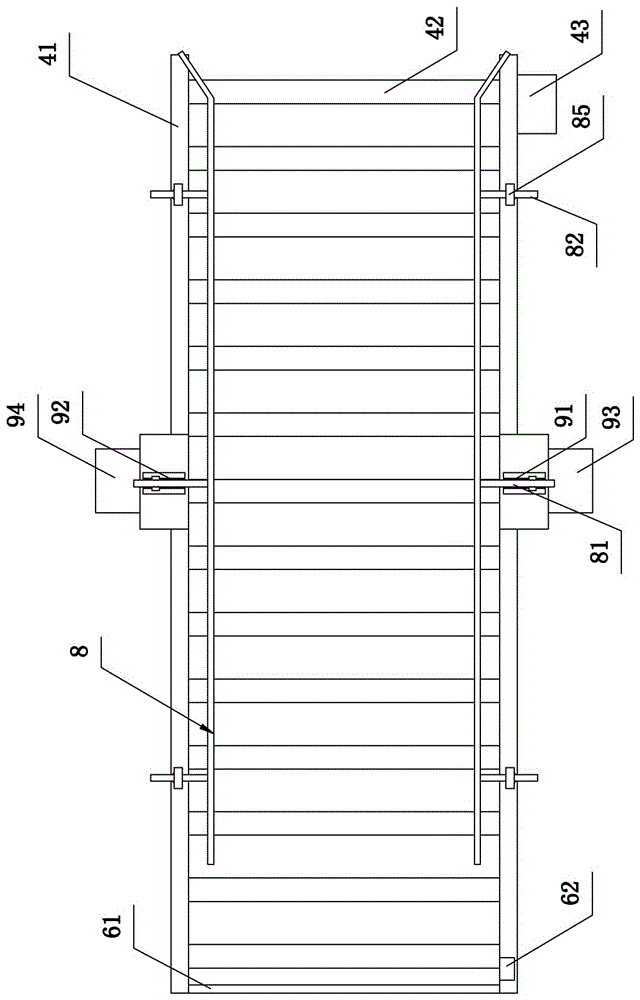

[0045] refer to figure 1 , figure 2 , image 3 and Figure 4 . An automatic palletizing equipment for cartons, comprising a steering manipulator 1 and an automatic gluing machine 2, the automatic gluing machine 2 is installed on the upper side of a discharge conveyor belt 3, and also includes a Grabbing conveyor belt 4 connected to the output end of belt 3. The junction of the grab conveyor belt 4 and the discharge conveyor belt 3 is equipped with a discharge limit mechanism 5 that can limit the movement of the carton, and the output end of the grab conveyor belt 4 is equipped with a grab limit mechanism 6. The discharge limit mechanism 5 is signal-connected with the steering manipulator 1 , and the transmission speed of the grabbing conveyor belt 4 is higher than the transmission speed of the discharge conveyor belt 3 . By setting the discharge limi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com