Deep supercooling preparation method of graphene reinforced magnesium-based composite material

A composite material and graphene technology, which is applied in the field of deep undercooling preparation of graphene-reinforced magnesium-based composite materials, can solve problems such as poor surface quality and mechanical properties, complicated preparation process, and long preparation cycle, and achieve surface quality and Poor mechanical properties, simple preparation process, and short preparation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

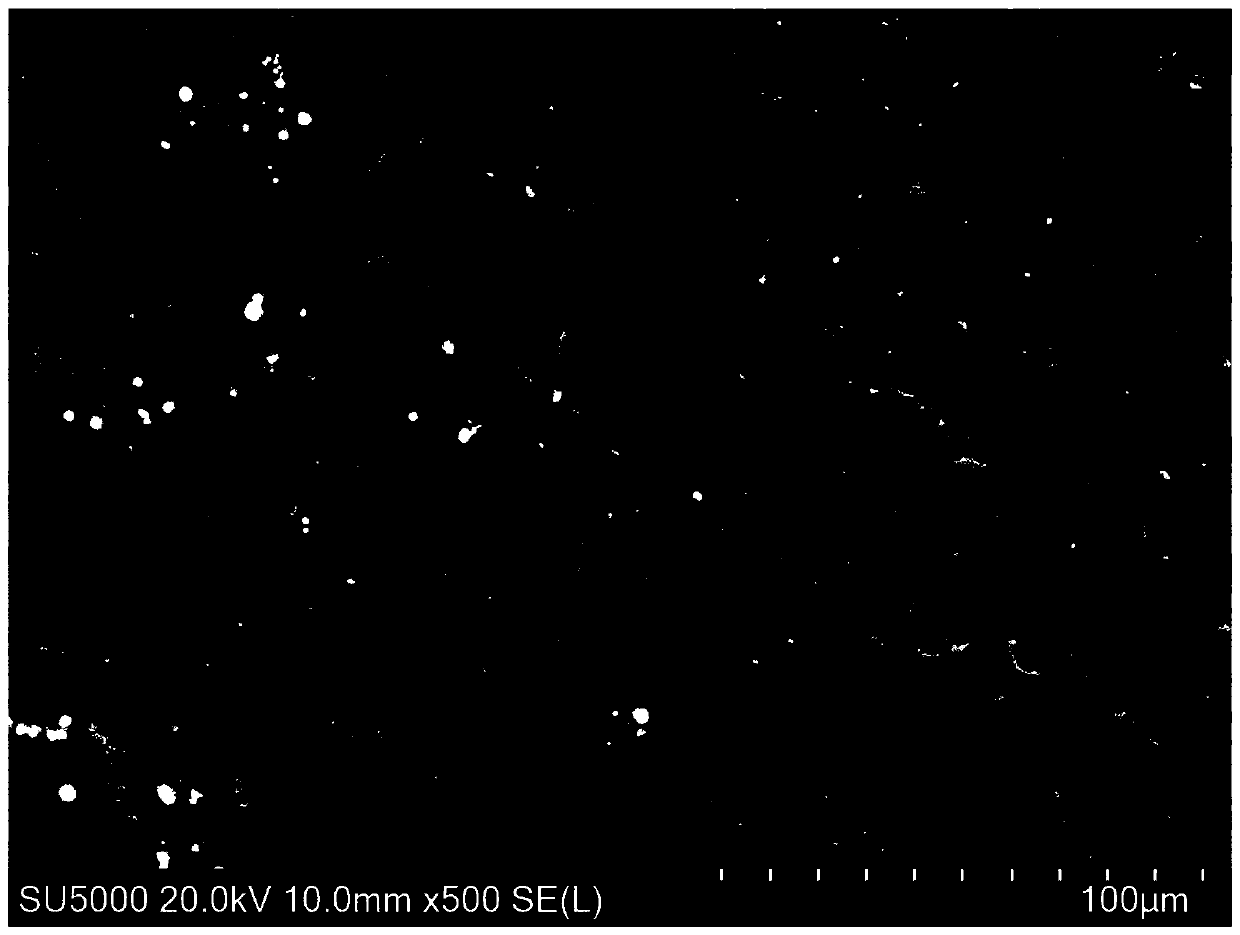

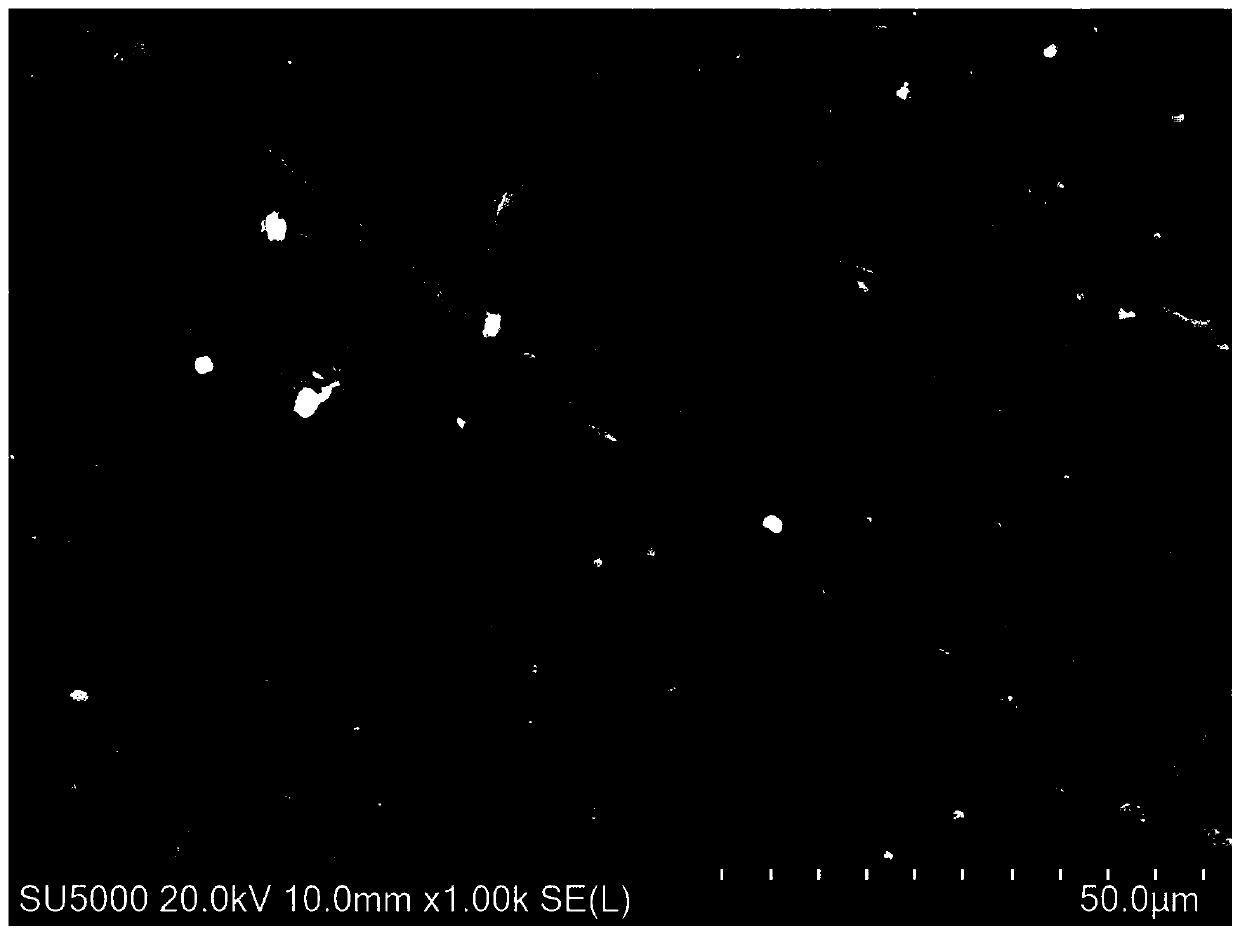

Image

Examples

Embodiment Construction

[0031] A kind of deep subcooling preparation method of graphene-reinforced magnesium-based composite material, this method is to adopt following steps to realize:

[0032] 1) Prepare the following materials: magnesium alloy block 100g±1g, graphene powder 5g±1g, absolute ethanol 1000mL±1mL, diboron trioxide 50g±1g, argon gas 800000cm 3 ±100cm 3 ;

[0033] 2) Pour absolute ethanol into the ultrasonic cleaning machine, and then put the quartz crucible and magnesium alloy block into the ultrasonic cleaning machine for cleaning for at least 6 minutes, thereby removing the surface impurities of the quartz crucible and magnesium alloy block;

[0034] 3) Weigh 50g ± 0.001g of the magnesium alloy block, and then mechanically cut the magnesium alloy block into pieces, thereby obtaining magnesium alloy particles with a diameter ≤ 3mm;

[0035] 4) Preparation of graphene-magnesium alloy mixed powder:

[0036] 4.1) Weigh 0.5g±0.001g of graphene powder;

[0037] 4.2) Ultrasonic disperse...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com