Method for improving glutamic acid fermentation conversion rate

A technology of glutamic acid and conversion rate is applied in the field of improving the conversion rate of glutamic acid fermentation to achieve the effects of ensuring dissolved oxygen in fermentation, reducing fermentation volume, and promoting the release to extracellular space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A method for improving the conversion rate of glutamic acid fermentation, comprising the steps of:

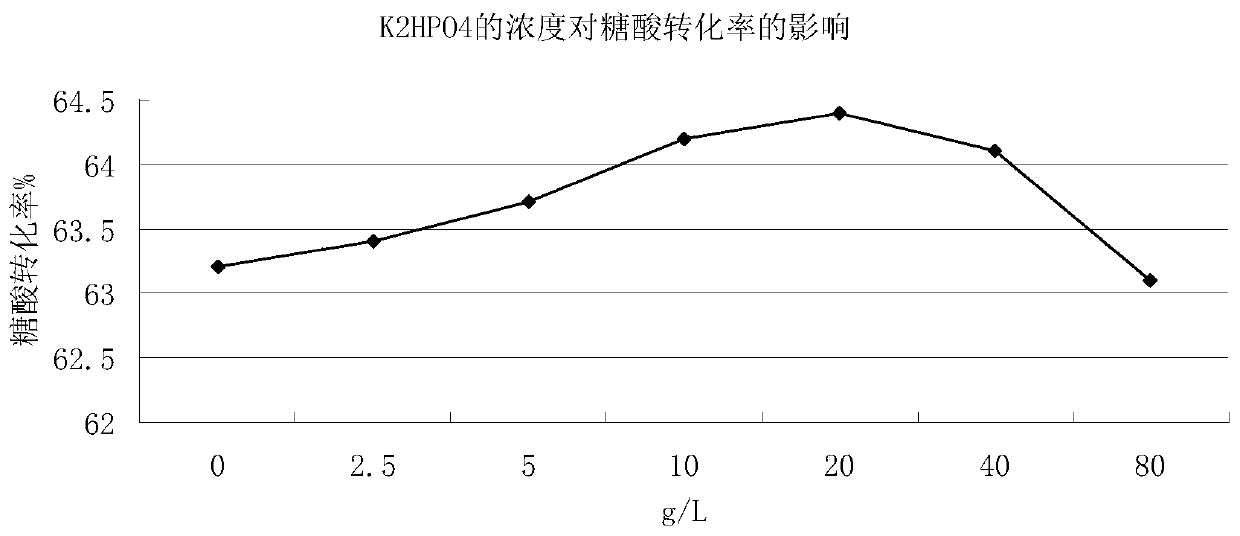

[0032] Brevibacterium flavum GDK-9 seed solution (OD 600nm 12) Insert 8% inoculum size into a 1000L fermenter equipped with 500L fermentation medium A for fermentation and cultivation, ferment and cultivate for 18h, then add 100L of fermentation medium B, continue to ferment and cultivate for 30h, and collect the fermented liquid; During the process, the fermentation temperature was controlled at 35°C, the ventilation ratio was 1:0.9, and the stirring speed was 300r / min. The residual sugar was maintained at not less than 1.0% by feeding glucose with a mass percentage concentration of 65%, and the pH was controlled by feeding ammonia water to 6.5. Feed defoaming agent to defoam; when fermented to 30h, feed K with a concentration of 20g / L at a flow rate of 5ml / min 2 HPO 4 , 2h before the end of fermentation, stop feeding K 2 HPO 4 .

[0033] The preparation method of ...

Embodiment 2

[0036] A method for improving the conversion rate of glutamic acid fermentation, comprising the steps of:

[0037] Brevibacterium flavum GDK-9 seed solution (OD 600nm 12) Insert 8% inoculum into a 1000L fermenter equipped with 500L fermentation medium A to carry out fermentation culture, ferment and cultivate for 24 hours, then add 100L fermentation medium B, continue to ferment and cultivate for 24 hours, and collect the fermented liquid; the whole fermentation culture During the process, the fermentation temperature was controlled at 35°C, the ventilation ratio was 1:0.8, and the stirring speed was 300r / min. The residual sugar was maintained at not less than 1.0% by feeding glucose with a mass percentage concentration of 60%, and the pH was controlled by feeding ammonia water to 6.7. Feed defoaming agent to defoam; when fermented to 30h, feed K with a concentration of 15g / L at a flow rate of 5ml / min 2 HPO 4 , until the end of fermentation. The preparation method of descri...

Embodiment 3

[0044] 1. Based on Comparative Example 1, CeCl was studied 3 Effects of rare earth salts on cell concentration, glutamic acid content and sugar-acid conversion rate.

[0045] Set CeCl 3 The added concentration is 0, 2.5, 5, 10, 20, 40mg / L, with CeCl 3 With the increase of the addition amount, the cell concentration and glutamic acid content both increased. When the addition amount was 10mg / L, the cell concentration and glutamic acid content reached the peak value. showed a downward trend, but the sugar-acid conversion rate did not change significantly during the whole process; indicating that the low concentration of CeCl 3 Rare earth salts can promote the proliferation of strains and increase the activity of glutamate-related synthetases, thereby increasing the production of glutamate. However, too high a concentration will cause the strain to proliferate and die, and the production of glutamate will decrease accordingly.

[0046] 2. Set CeCl 3 The addition amount was 10m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com