Chlorinated polypropylene paint and preparation method thereof

A technology for chlorinated polypropylene and coatings, applied in anti-corrosion coatings, coatings, etc., can solve problems such as performance differences, and achieve the effects of improving boiling resistance, improving uniformity, and reducing water vapor penetration paths

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

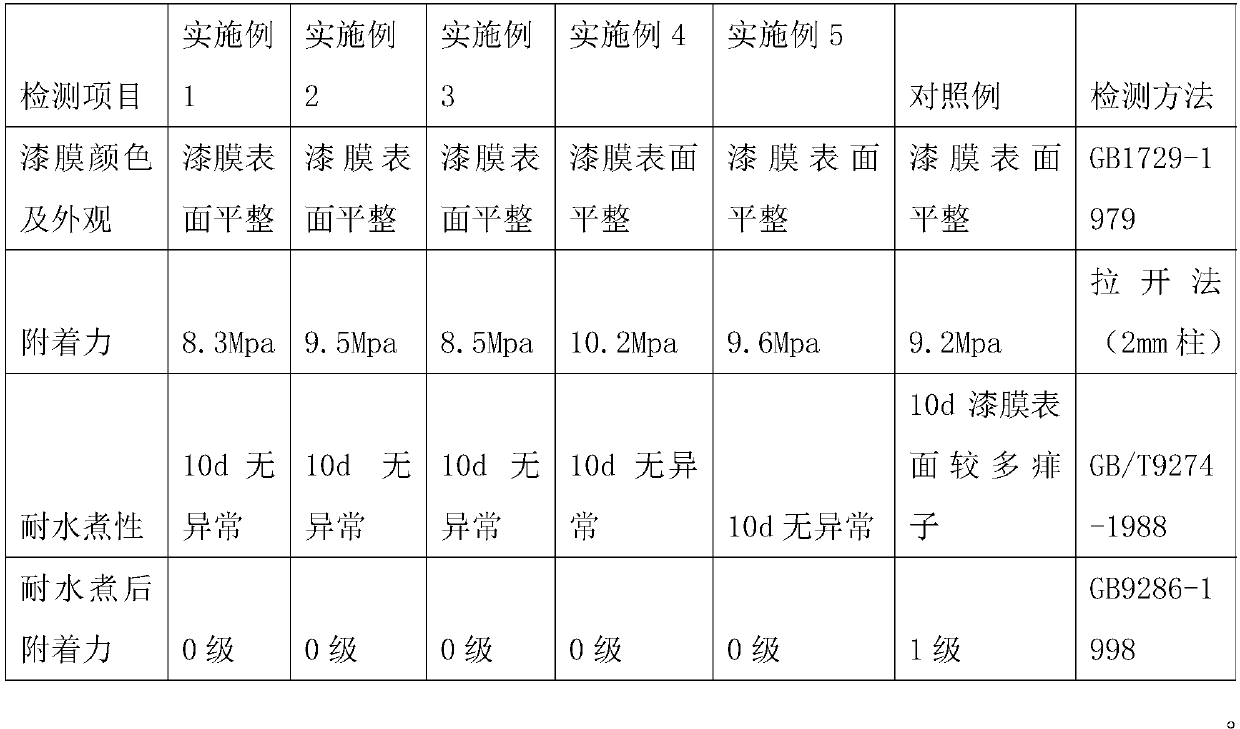

Examples

Embodiment 6

[0050] A kind of chlorinated polypropylene coating, the raw material of this coating comprises the component of following parts by weight:

[0051] Chlorinated polypropylene resin: 30;

[0052] Coumarone Resin: 5;

[0053] Dispersant: 2;

[0054] Defoamer: 1;

[0055] Organic bentonite: 1;

[0056] Titanium dioxide: 8;

[0058] Non-leafing aluminum silver paste: 1;

[0059] Leveling agent: 1;

[0060] Solvent: 20;

[0061] Absolute ethanol: 0.5.

[0062] Wherein: the molecular weight of the chlorinated polypropylene resin is 40000-60000, and the chlorine content is between 5% and 15%. The softening point of the above-mentioned coumarone resin is between 90°C and 100°C; the solvent is acetone.

[0063] Prepared by:

[0064] (1) Add organic bentonite in the solvent under stirring state, the mass ratio of solvent mass and organic bentonite is 3:1, adjust the rotating speed according to its stirring state, wait for its state to be uniform, without...

Embodiment 7

[0069] A kind of chlorinated polypropylene coating, the raw material of this coating comprises the component of following parts by weight:

[0070] Chlorinated polypropylene resin: 40;

[0071] Coumarone Resin: 10;

[0072] Dispersant: 2.5;

[0073] Defoamer: 1;

[0074] Organic bentonite: 1;

[0075] Titanium dioxide: 6;

[0077] Non-leafing aluminum silver paste: 1.5;

[0078] Leveling agent: 1.5;

[0079] Solvent: 25;

[0080] Absolute ethanol: 1.

[0081] Wherein: the molecular weight of the chlorinated polypropylene resin is 40000-60000, and the chlorine content is between 5% and 15%. The softening point of the coumarone resin is between 90°C and 100°C; the solvent is methyl isobutyl ketone.

[0082] Prepared by:

[0083] (1) Add the organic bentonite to the solvent under stirring, the mass ratio of the solvent mass to the organic bentonite is 1:1, adjust the speed according to the stirring state, and wait for the state to be uniform ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com