Preparation method of polyvinylidene fluoride composite compound, polyvinylidene fluoride composite film, its preparation method and application

A polyvinylidene fluoride and composite membrane technology, which is used in its preparation, the preparation of polyvinylidene fluoride composite mixtures, and the field of polyvinylidene fluoride composite membranes, can solve the problems of incapable of anti-pollution materials and poor film-forming properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A preparation method of a polyvinylidene fluoride composite film, comprising the following steps:

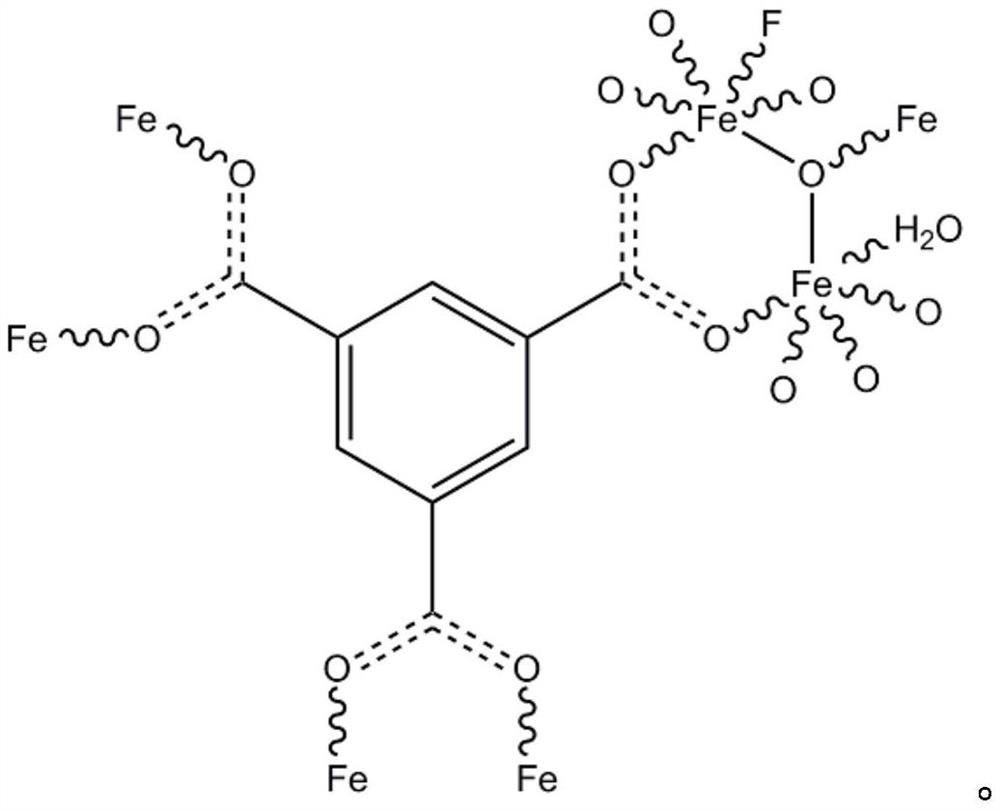

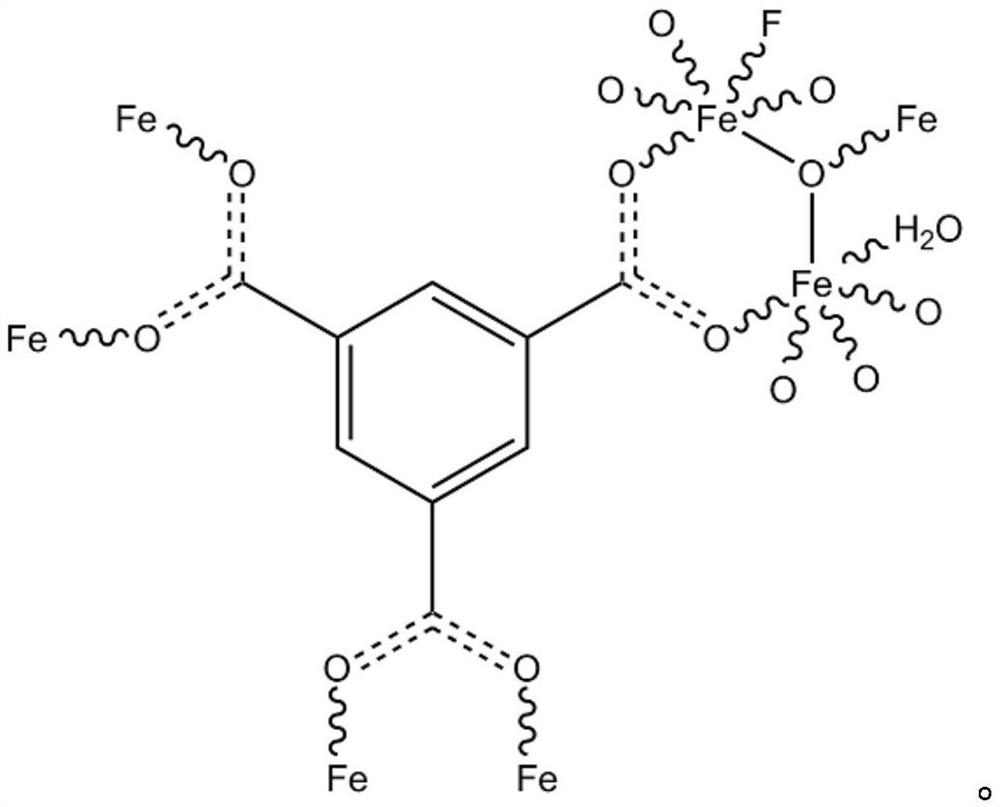

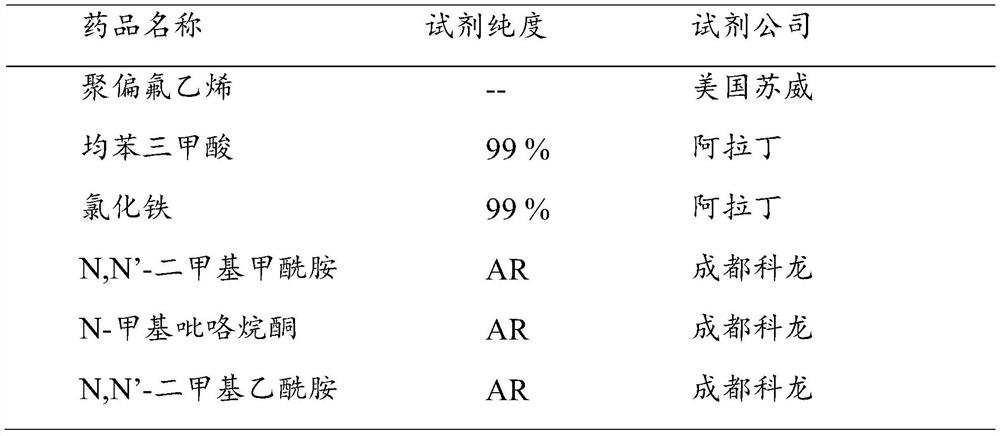

[0045] (1) 0.21g trimesic acid and 0.675g FeCl3 Disperse in 50mL DMF (N,N'-dimethylformamide), react at 120°C for 20h, stop the reaction, cool to 20°C, wash off unreacted trimeric acid with ethanol, dry at 80°C, Crystal A is obtained, and the crystal A is ground with a mortar to obtain powder A, which is the metal organic framework material MIL-100-Fe.

[0046] (2) Add 0.5g of metal-organic framework material MIL-100-Fe and 8g of N-methylpyrrolidone into the reactor, ultrasonically disperse at room temperature for 2 hours, then add 1.5g of polyvinylidene fluoride into the reactor, and stir at 60°C 4h, the composite mixture was obtained.

[0047] (3) Vacuum defoaming and aging treatment of the composite mixture to obtain the modified casting solution.

[0048] (4) Apply the spin coating method (the spin coating speed is 200r / min, and the spin coating time is 20s) to coat...

Embodiment 2

[0057] A preparation method of a polyvinylidene fluoride composite film, comprising the following steps:

[0058] (1) 0.21g trimesic acid and 0.675g FeCl 3 Disperse in 50mL DMF (N,N'-dimethylformamide), react at 120°C for 20h, stop the reaction, cool to 20°C, wash off unreacted trimeric acid with ethanol, dry at 80°C, Crystal A is obtained, and the crystal A is ground with a mortar to obtain powder A, which is the metal organic framework material MIL-100-Fe.

[0059] (2) Add 1g metal-organic framework material MIL-100-Fe and 7.5g N-methylpyrrolidone into the reactor, ultrasonically disperse at room temperature for 2 hours, then add 1.5g polyvinylidene fluoride into the reactor, and stir at 60°C 4h, the composite mixture was obtained.

[0060] (3) Vacuum defoaming and aging treatment of the composite mixture to obtain the modified casting solution.

[0061] (4) Spin coating method (the spin coating speed is 1000r / min, and the spin coating time is 30s) is used to coat the mod...

Embodiment 3

[0068] A preparation method of a polyvinylidene fluoride composite film, comprising the following steps:

[0069] (1) 0.21g trimesic acid and 0.675g FeCl 3 Disperse in 50mL DMF (N,N'-dimethylformamide), react at 120°C for 20h, stop the reaction, cool to 20°C, wash off unreacted trimeric acid with ethanol, dry at 80°C, Crystal A is obtained, and the crystal A is ground with a mortar to obtain powder A, which is the metal organic framework material MIL-100-Fe.

[0070] (2) Add 1g metal-organic framework material MIL-100-Fe and 7g N-methylpyrrolidone into the reactor, ultrasonically disperse at room temperature for 2h, then add 2g polyvinylidene fluoride into the reactor, stir at 60°C for 4h, A compound mixture is obtained.

[0071] (3) Vacuum defoaming and aging treatment of the composite mixture to obtain the modified casting solution.

[0072] (4) Spin-coating method (spin-coating speed of 300r / min, spin-coating time of 90s) is used to coat the modified casting solution on ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com