Raw material proportioning equipment for jade imitation

A raw material and jade technology, which is applied in the field of raw material proportioning equipment for jade imitation, can solve the problems of inability to flexibly adjust the color depth of the dyeing agent, unable to quickly produce jade imitation products, etc., and achieve the effect of accelerating the solidification rate and ensuring stable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

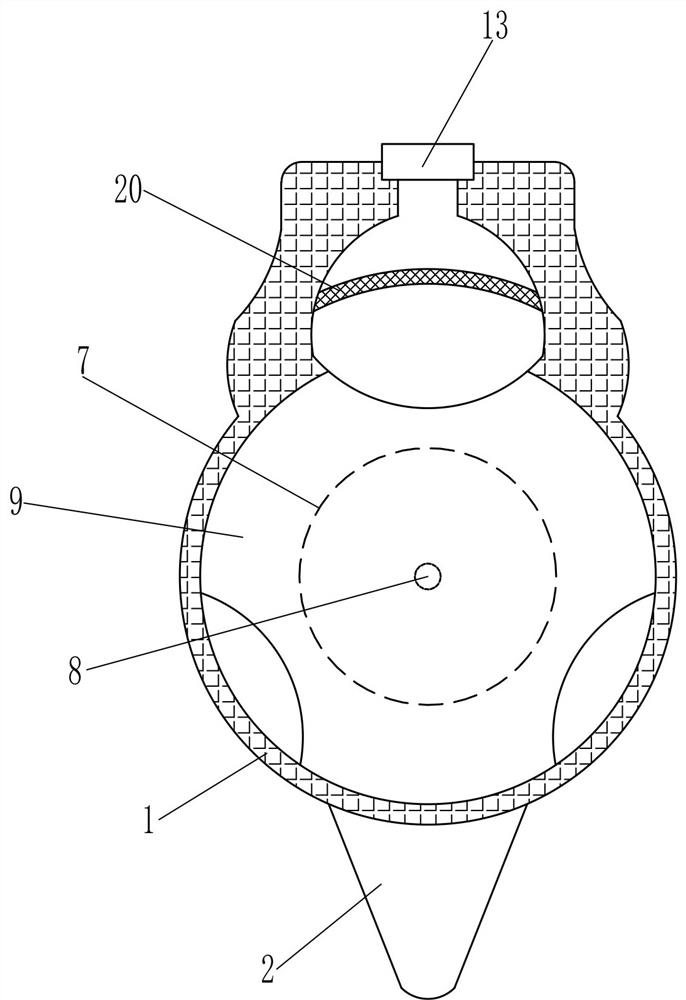

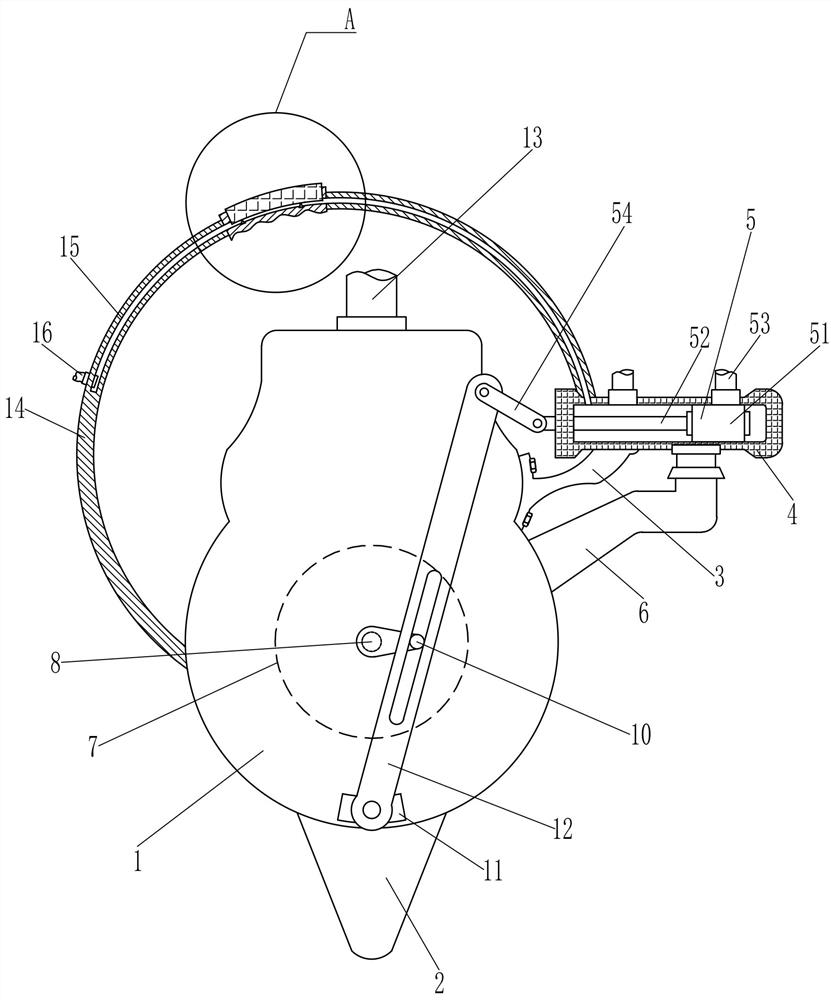

[0019] A kind of raw material proportioning equipment for jade imitation, such as Figure 1-2 As shown, it includes a housing 1, a discharge pipe 2, an installation seat 3, an installation body 4, a color matching device 5, a liquid discharge pipe 6, a driving motor 7, a rotating shaft 8, a pushing plate 9, a pushing rod 10, and a mounting block 11 , groove rod 12 and feed pipe 13, the lower part of the housing 1 is provided with a discharge pipe 2, the upper part of one side of the housing 1 is provided with a mounting seat 3, the mounting seat 3 is provided with an installation body 4, and a color matching is arranged inside the installation body 4 Device 5, the lower part of the color matching device 5 is connected with a drain pipe 6, the end of the drain pipe 6 is connected with the housing 1, the rear side of the housing 1 is provided with a driving motor 7, the output shaft of the driving motor 7 is connected with a rotating shaft 8, and the middle part of the rotating s...

Embodiment 2

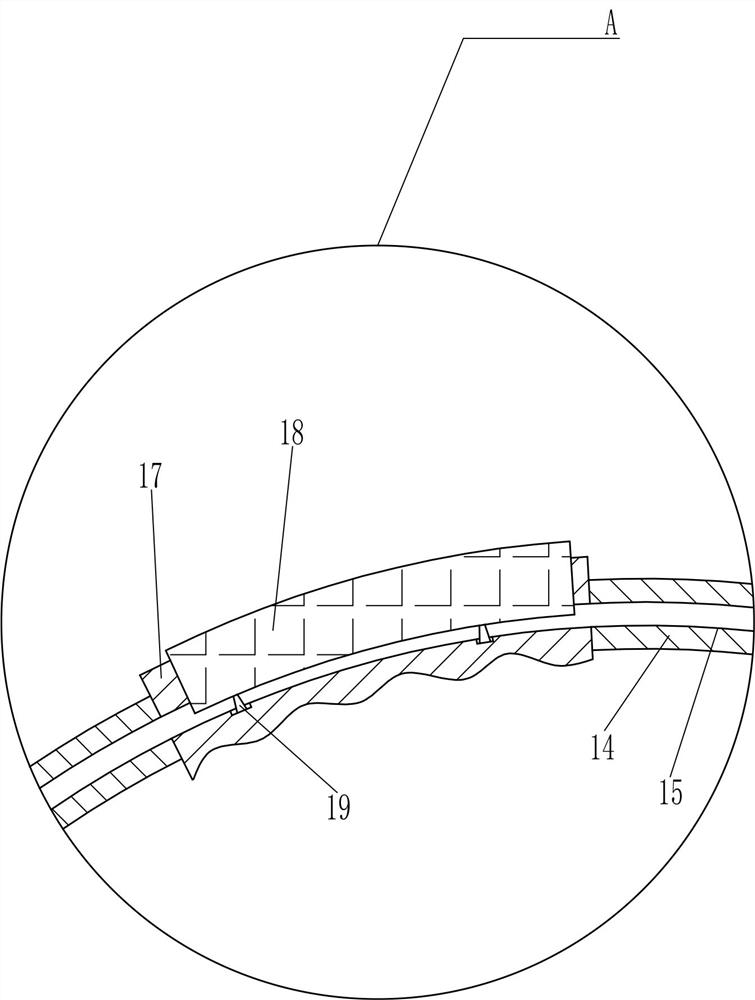

[0023] On the basis of Example 1, such as figure 1 and image 3 As shown, it also includes an arc column 14, a liquid injection tube 16, a handle 17, a sliding block 18 and a compression spring 19. The housing 1 is provided with an arc column 14, and an arc groove 15 is arranged in the arc column 14. , one side of the top of the mounting body 4 is also provided with the arc groove 15, the lower part of the side of the arc column 14 is connected with a liquid injection pipe 16, the arc column 14 is provided with a handle 17, and the handle 17 is slidingly connected with a sliding A compression spring 19 is connected between the block 18, the sliding block 18 and the handle 17.

[0024] When the equipment is in operation, one end of the liquid injection pipe 16 is connected to the supply end of the curing agent. When the equipment is in normal operation, the worker needs to hold the sliding block 18 tightly so that the sliding block 18 fits closely with the inner wall of the ha...

Embodiment 3

[0026] On the basis of Example 2, such as figure 2 As shown, an arc-shaped screen 20 is also included, and the upper part of the housing 1 is provided with an arc-shaped screen 20 .

[0027] The curved screen 20 is used to filter the resin to prevent larger particles mixed in the resin from flowing into the equipment, thereby achieving the effect of ensuring the stable operation of the equipment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com