Plug-in type multi-vehicle type transforming tray for automobile assembly and installation in automobile factory

A plug-in type, the technology of the OEM, applied in the direction of hand-held tools, workpiece clamping devices, manufacturing tools, etc., can solve the problems of heavy weight of front seats, inconvenient assembly, low production efficiency, etc., to reduce work Efficiency, convenient installation and processing, and increased convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

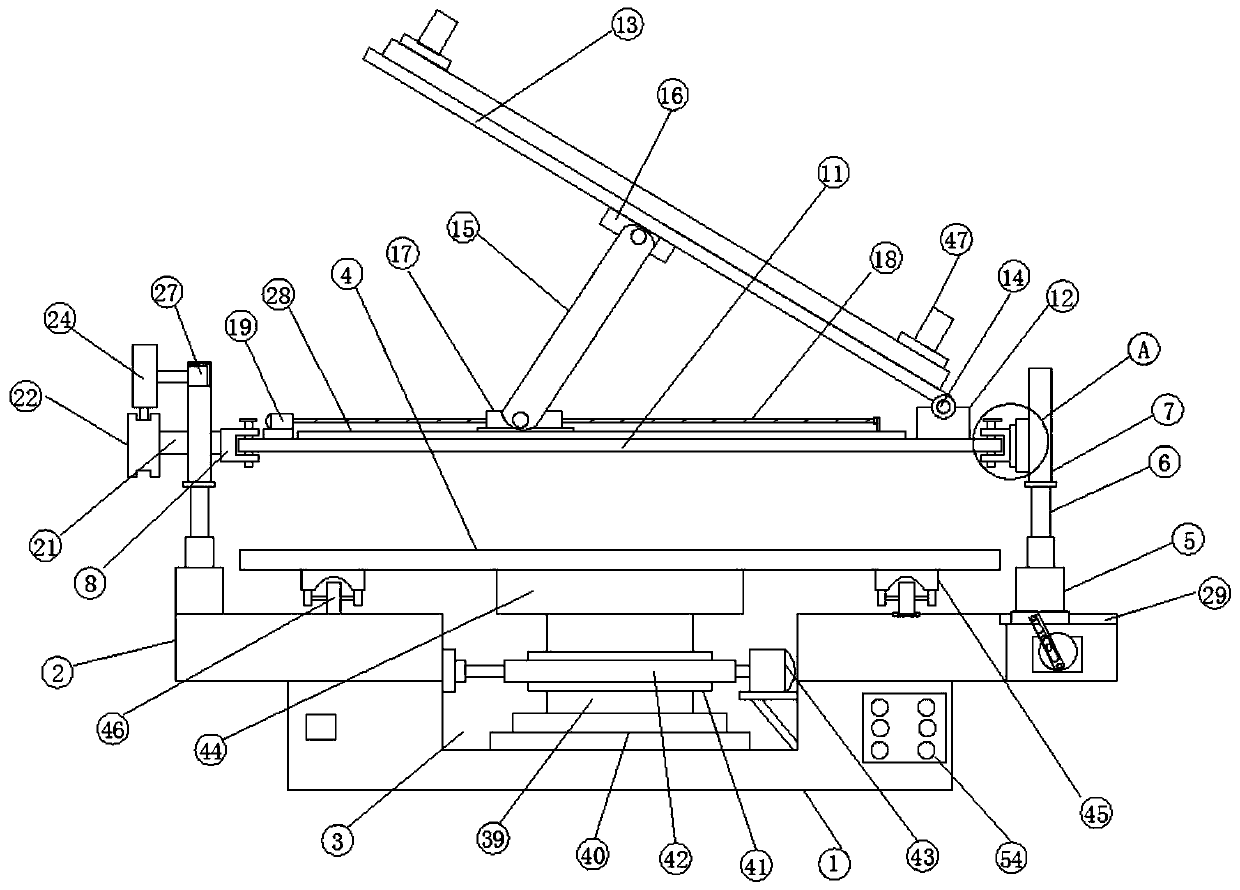

[0032] see Figure 1-5 , according to an embodiment of the present invention, a plug-in type multi-vehicle conversion pallet for assembly of automobiles in an entire vehicle factory includes a base 1, and a support plate 2 is fixed on one side of the base 1, and the support plate 2 and the base 1 is provided with a placement slot 3 in the middle, and an operation table 4 is provided above the placement slot 3, and a rolling device is provided on both sides of the operation table 4, and one side of the operation table 4 is connected with the first rotating device , the first rotating device is arranged inside the placement groove 3, and the two sides of the operating table 4 are respectively provided with a first hydraulic cylinder and a second hydraulic cylinder 5 on the support plate 2, and the first hydraulic cylinder 5 The output ends of the hydraulic cylinder and the second hydraulic cylinder 5 are all provided with a hydraulic telescopic rod 6, and the other end of the hy...

Embodiment 2

[0034] see figure 1 , for the limiting device, the limiting device includes a limiting chute 28, the limiting chute 28 is fixed to one side of the bottom plate 11, and the internal sliding of the limiting chute 28 is provided with a limiting Slider, the side of the limit slider away from the limit chute 28 is fixedly connected with the first nut 17, the limit device can limit the first nut, avoiding the first threaded rod 18 rotates and drives the first nut 17 to rotate synchronously, and the limit device can realize the movement of the first nut 17 on the first threaded rod 18, thereby driving the stability of the movement of the movable rod 15, and it can realize the rotating plate 13 around With the rotation of the connecting hinge 14, the function of angle adjustment can be realized.

Embodiment 3

[0036] see figure 1 , 3 , for the mobile device, the mobile device includes a first slide rail 29, the first slide rail 29 is opened on one side of the support plate 2, and a sliding block 30 is arranged inside the first slide rail 29, One side of the sliding block 30 is fixed with a first protrusion 31, the first protrusion 31 is arranged in the first moving groove 32, and one side of the first moving groove 32 is provided with a second moving groove 33 , the first moving groove 32 and the second moving groove 33 are opened on the swing rod 34, one end of the swing rod 34 is movably connected with the disc 36 through the movable pin 35, and the disc 36 The middle of one side is connected with the output end of the third motor 37, and the eccentric part of the disc 36 is fixed with a second protrusion 38, and one end of the second protrusion 38 is arranged inside the second moving groove 33 , the mobile device can drive the movement of the second hydraulic cylinder 5, the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com