Large I-shaped beam welding platform and welding method

A welding platform and I-beam technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve problems such as high investment, high rework rate, and unpredictable deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

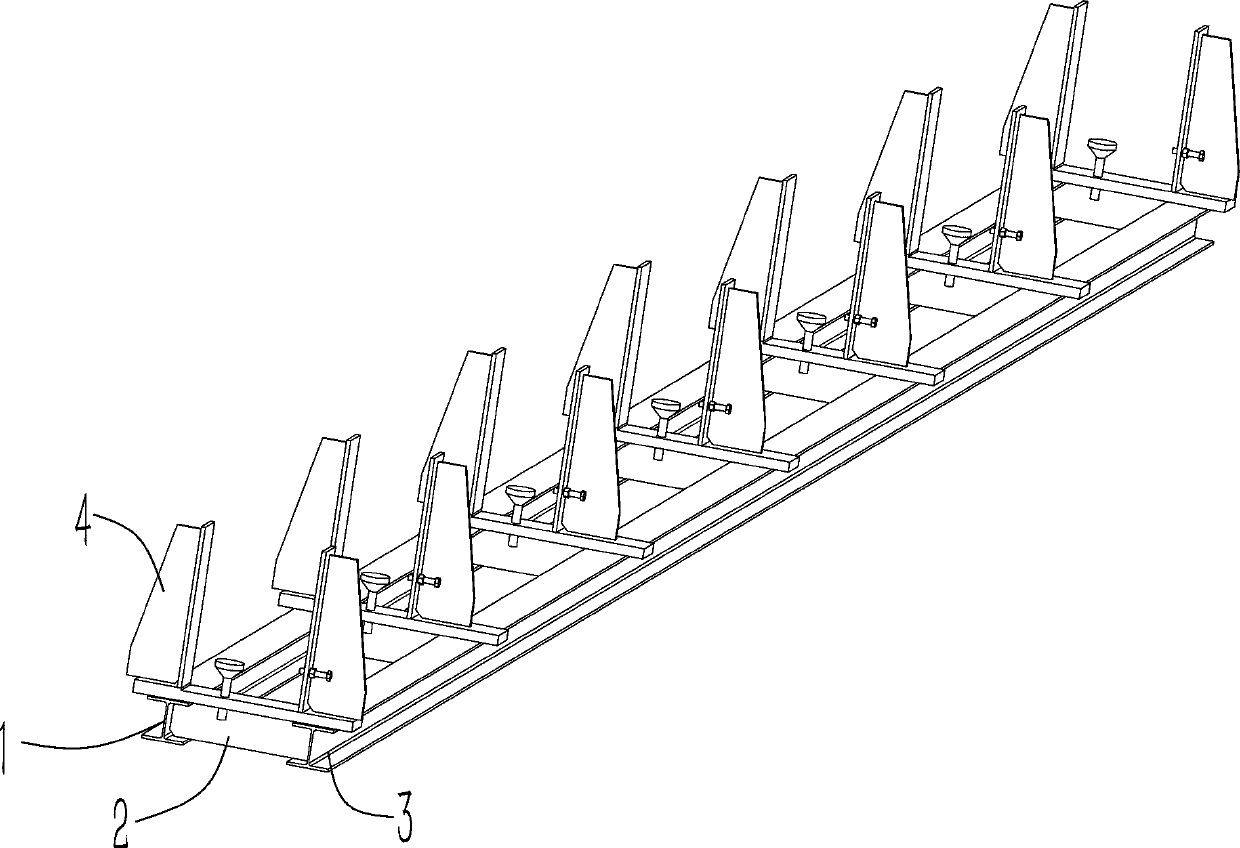

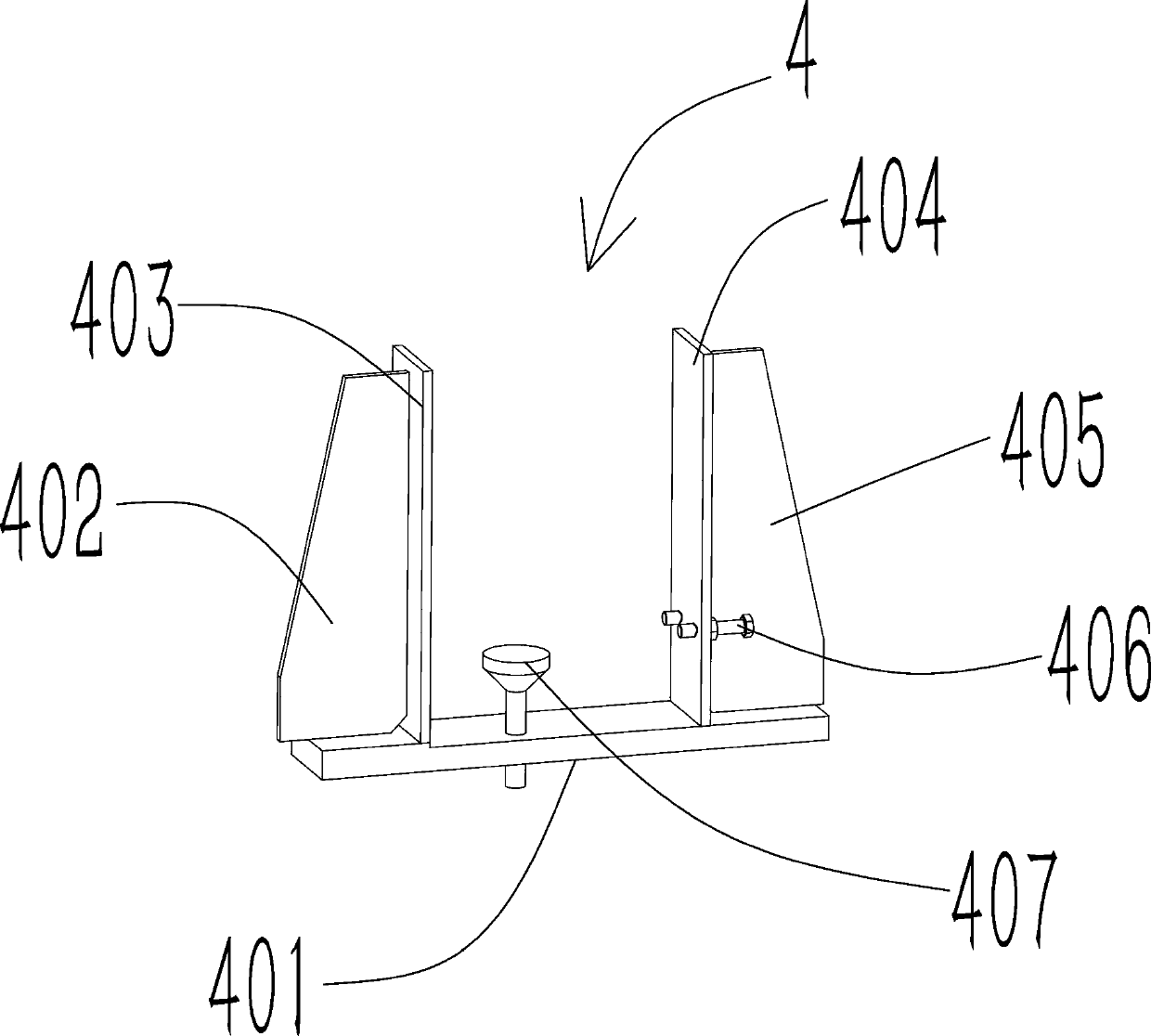

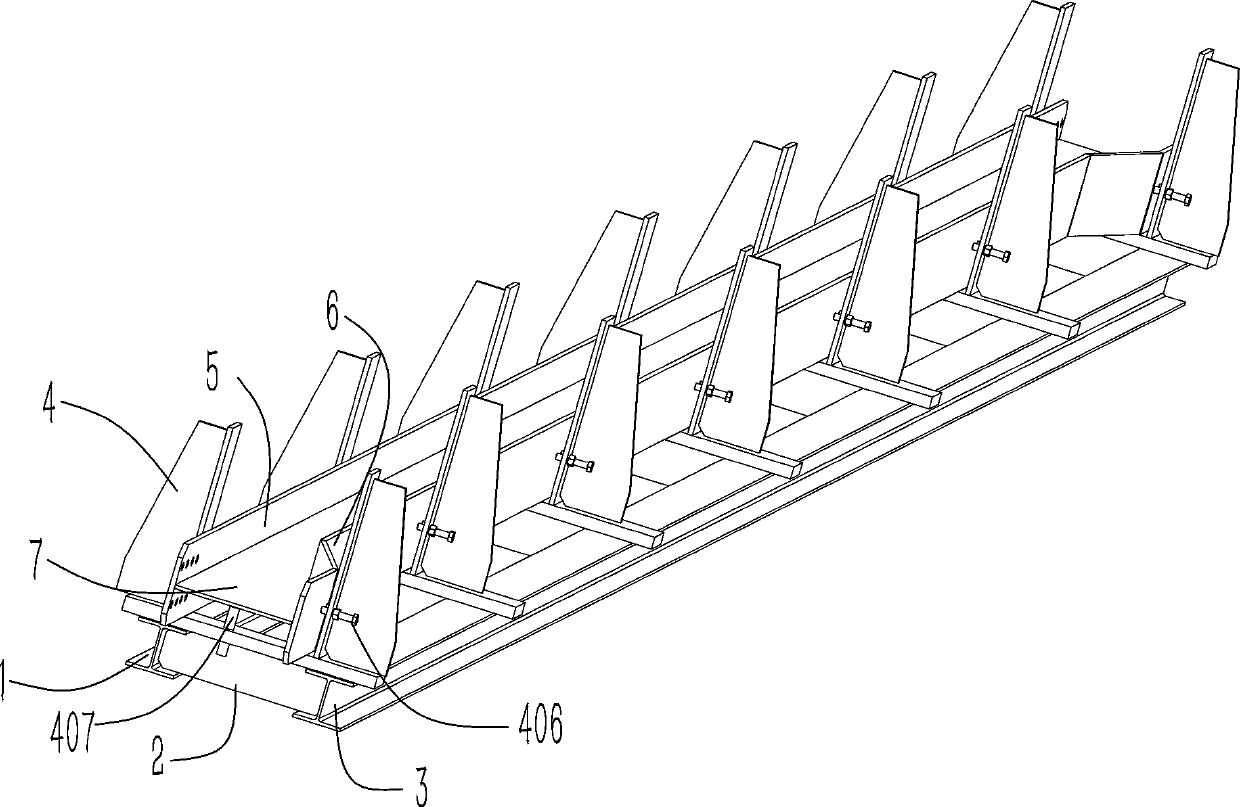

[0025] Such as Figure 1~4 As shown, a large-scale I-beam welding platform includes a first I-beam 1 and a second I-beam 3 placed side by side, and a plurality of Connecting plate 2, the first I-beam 1 and the second I-beam 3 are connected through a plurality of connecting plates 2, a positioning device 4 is provided above the connecting plate 2, and the large I-beam is placed on the positioning device In 4, the end face of the large I-beam is supported by pads 407, and the side of the large I-beam is locked and fixed by bolts 406. From this structure, the platform base is made of the first I-beam 1 and the second I-beam 3 Through the connection of multiple connecting plates 2, the stability and levelness of the base itself are guaranteed, and the levelness must also be ensured between multiple positioning devices 4 placed on the base. The large I-beam welded with the positioning device 4 as a reference can It has high verticality and horizontality.

[0026] In a preferred s...

Embodiment 2

[0033] Further illustrate in conjunction with embodiment 1, as Figure 1~4 As shown, when the I-beam is assembled and welded, the left side plate 5 leans against the first vertical plate 403; the height of the pad 407 is adjusted according to the welding height of the support plate 7; the support plate 7 is placed on the pad 407, One end of the support plate 7 leans against the left side plate 5; the right side plate 6 is leaned against the other end of the support plate 7, and the adjustment bolt 406 is pressed against the right side plate 6; the right side plate 6, the support plate 7 Weld the contact surface with the left side plate 5; loosen the bolt 406, hoist the large I-beam that has been initially welded to the submerged arc welding machine station for external full welding reinforcement, and the welding method of the H-beam and the I-beam is the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com