Hand bag

A handbag and portable technology, applied in the field of handbags, can solve the problems of high material cost, inconvenient operation, complex structure, etc., and achieve the effects of simplified production process, convenient operation and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

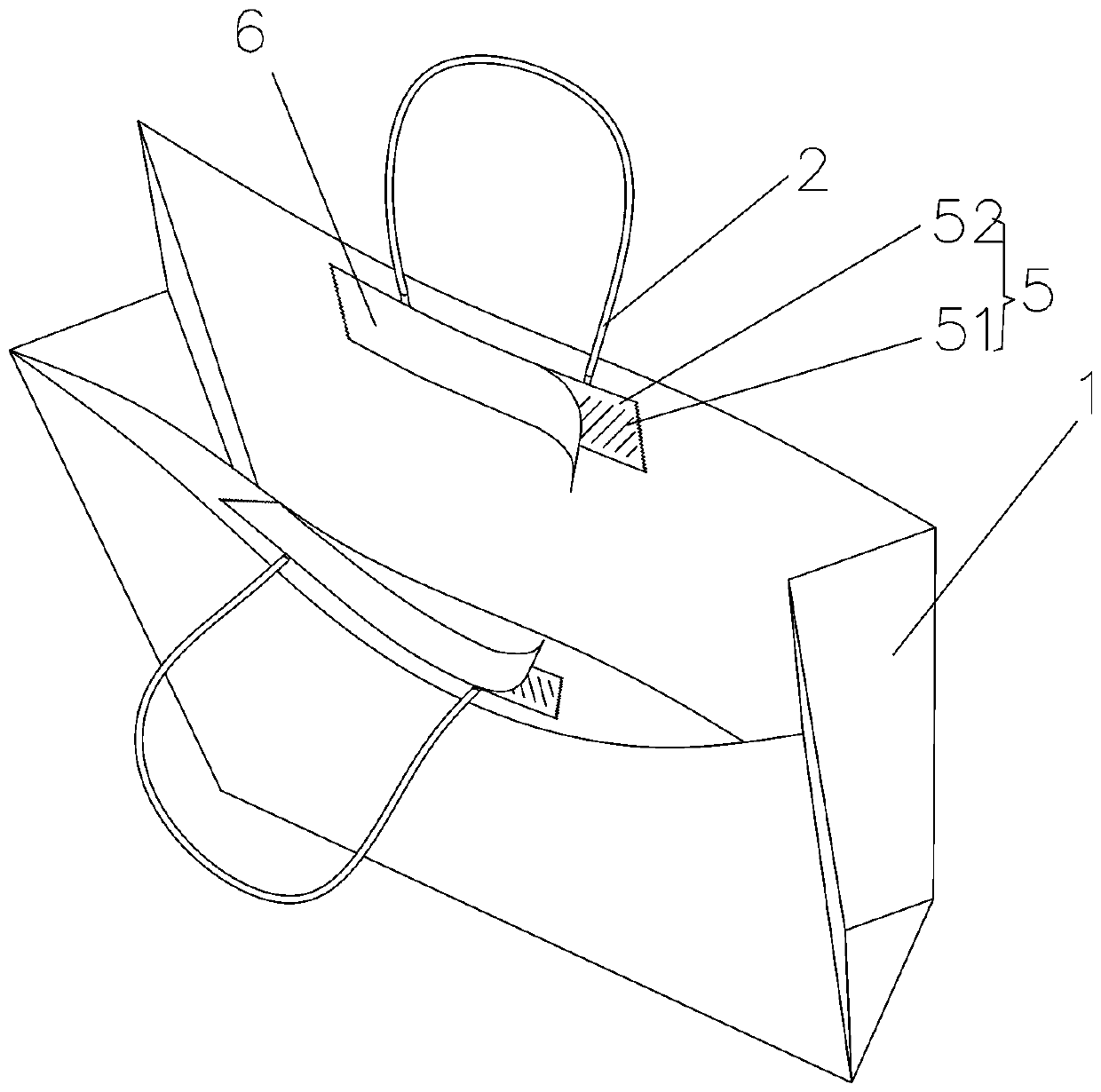

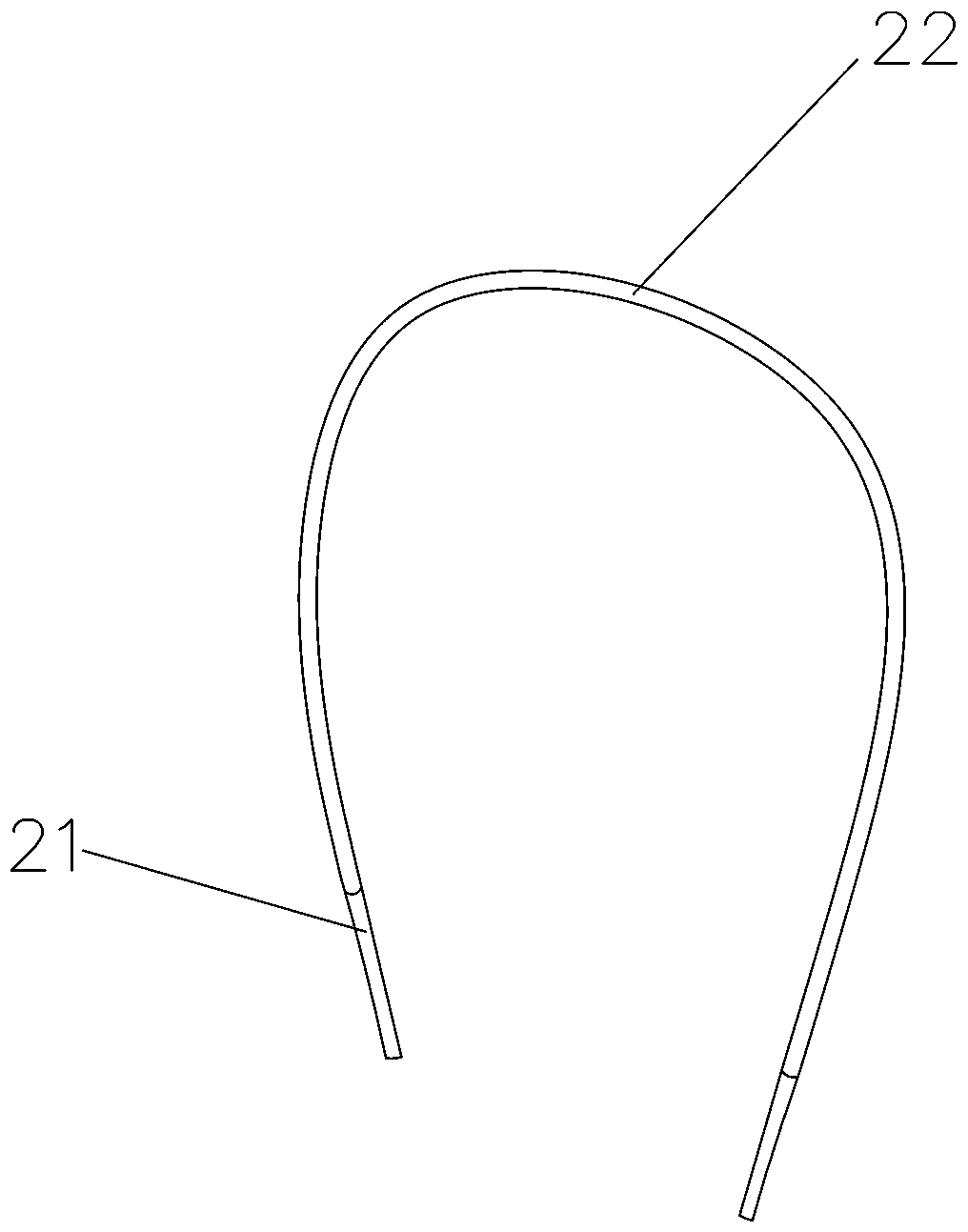

[0029] A kind of handbag of the present invention, embodiment is as figure 1 As shown in -4, it includes a bag body 1 with a bag mouth, and the two opposite inner sides of the bag body 1 are respectively provided with a hand rope 2, a first adhesive layer 3 and a sticker 4, and also includes a second adhesive layer 5 and release paper 6; such as image 3 As shown, both ends of each of the hand ropes 2 are adhesive parts 21 of a flat structure, and the middle section is a handle part 22; each of the stickers 4 is respectively arranged on two opposite inner sides of the bag body The side is adjacent to the position of the bag mouth, and the outer side of each sticker 4 and the corresponding adhesive part 21 of the hand rope 2 are all adhered to the bag body 1 through the corresponding first adhesive layer 3 On the corresponding inner side of the second adhesive layer 5, the second adhesive layer 5 is coated on the inner side of at least one of the stickers 4, and the release pa...

Embodiment 2

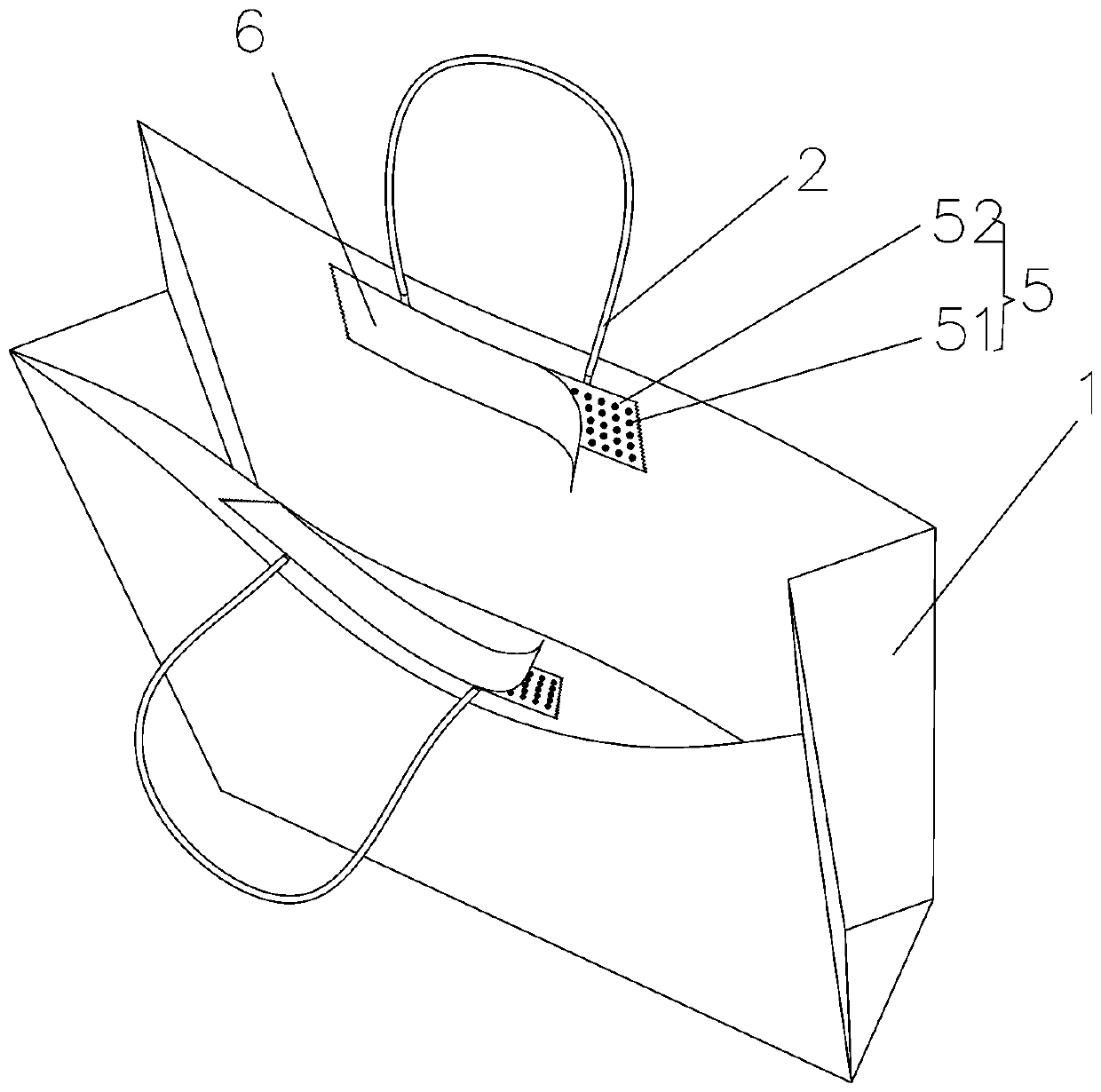

[0037] A kind of handbag of the present invention, embodiment two is as Figure 5 As shown in -8, the difference between this embodiment and the first embodiment is only that: the second adhesive layer 5 adopts a remoistened adhesive layer, and the release paper is omitted. Utilizing the characteristics of the remoistening adhesive, there will be almost no adhesive force when it is not sticky to water, and it will not bond the bag mouth together, so that the release paper can be saved, and the material cost can be further saved.

[0038] The invention is not only applicable to paper handbags, but also to handbags made of other materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com