Method for improving insulation space charge characteristics of polypropylene high-voltage direct-current cable

A cable insulation and high-voltage DC technology is applied in the field of improving the insulation space charge characteristics of polypropylene high-voltage DC cables. Improve dielectric strength and electrical aging resistance, improve space charge accumulation, and suppress space charge effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

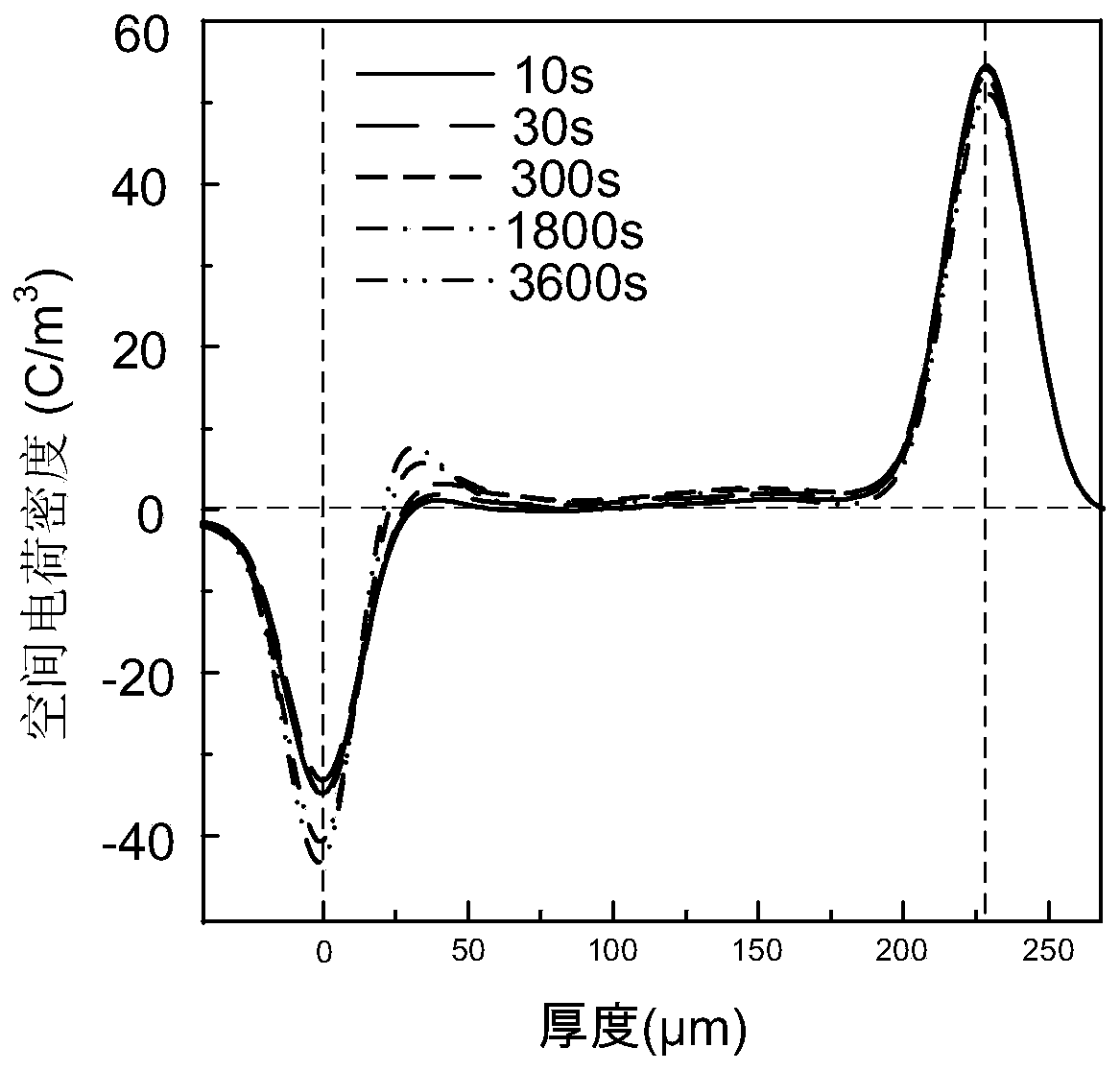

Embodiment 1

[0031] The technical solution adopted in this example is to melt and blend the polypropylene composite base material and the free radical scavenger in the following mass ratio, extrude and granulate to make a polypropylene-based high-voltage DC cable that uses free radicals to improve space charge characteristics Insulation material:

[0032] Polypropylene 85 parts

[0033] Ultra-low density polyethylene 15 parts

[0034] Free radical scavenger 622 0.3 parts

[0035] In this example, a free radical scavenger to improve the space charge characteristics of polypropylene high-voltage DC cable insulation material preparation steps is as follows:

[0036] 1. Fully mix polypropylene, ultra-low density polyethylene, and free radical scavenger according to the following parts by mass to obtain a mixture:

[0037] Polypropylene 85 parts

[0038] Ultra-low density polyethylene 15 parts

[0039] Free radical scavenger 622 0.3 parts;

[0040] 2. Put the mixture obtained in step 1 in...

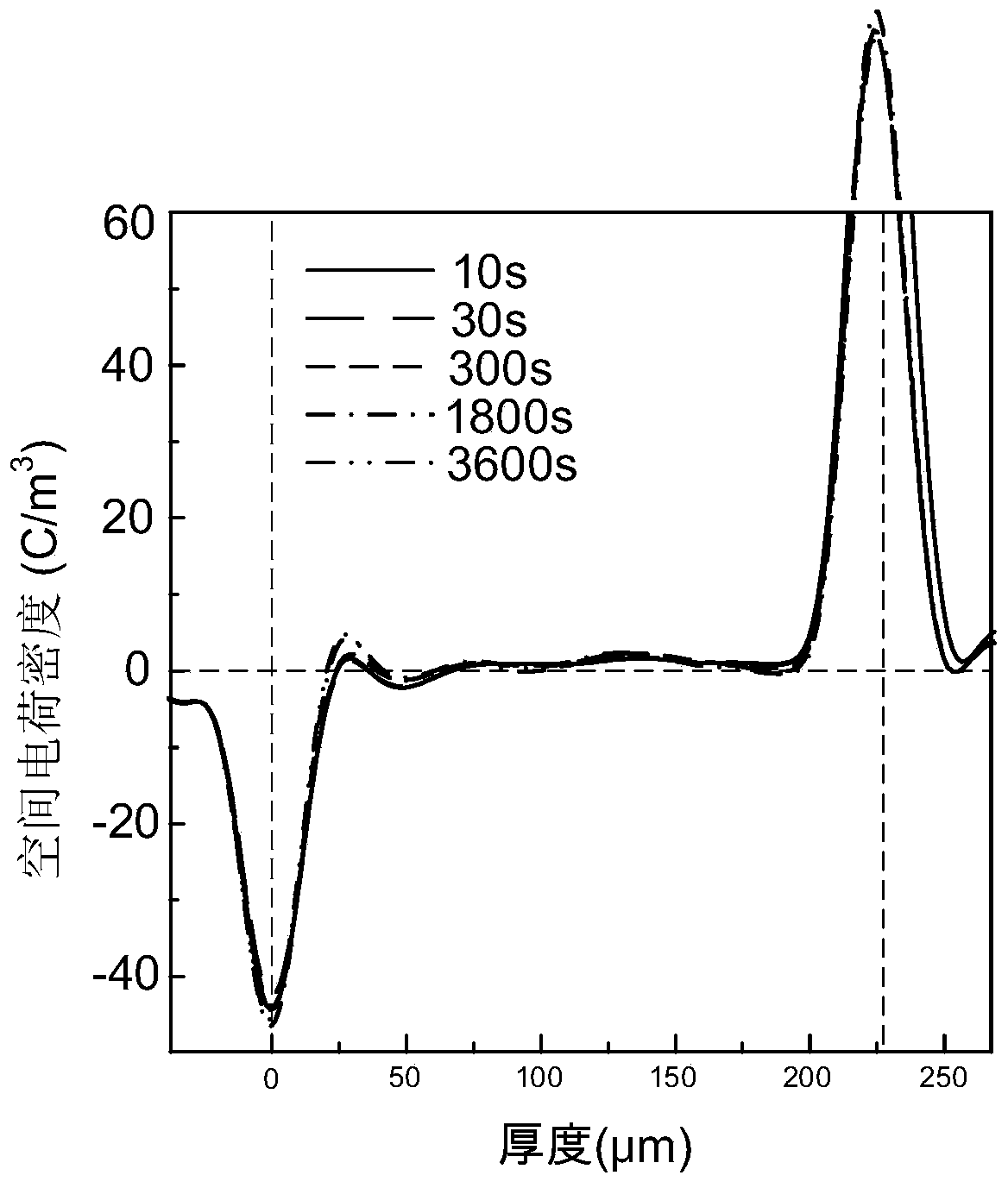

Embodiment 2

[0042] The technical solution adopted in this example is to melt and blend the polypropylene composite base material and the free radical scavenger in the following mass ratio, extrude and granulate to make a polypropylene-based high-voltage DC cable that uses free radicals to improve space charge characteristics Insulation material:

[0043] Polypropylene 85 parts

[0044] Ultra-low density polyethylene 15 parts

[0045] Free Radical Scavenger 770 0.3 parts

[0046] In this example, a free radical scavenger to improve the space charge characteristics of polypropylene high-voltage DC cable insulation material preparation steps is as follows:

[0047] 1. Fully mix polypropylene, ultra-low density polyethylene, and free radical scavenger according to the following parts by mass to obtain a mixture:

[0048] Polypropylene 85 parts

[0049] Ultra-low density polyethylene 15 parts

[0050] Free radical scavenger 770 0.3 parts;

[0051] 2. Put the mixture obtained in step 1 in...

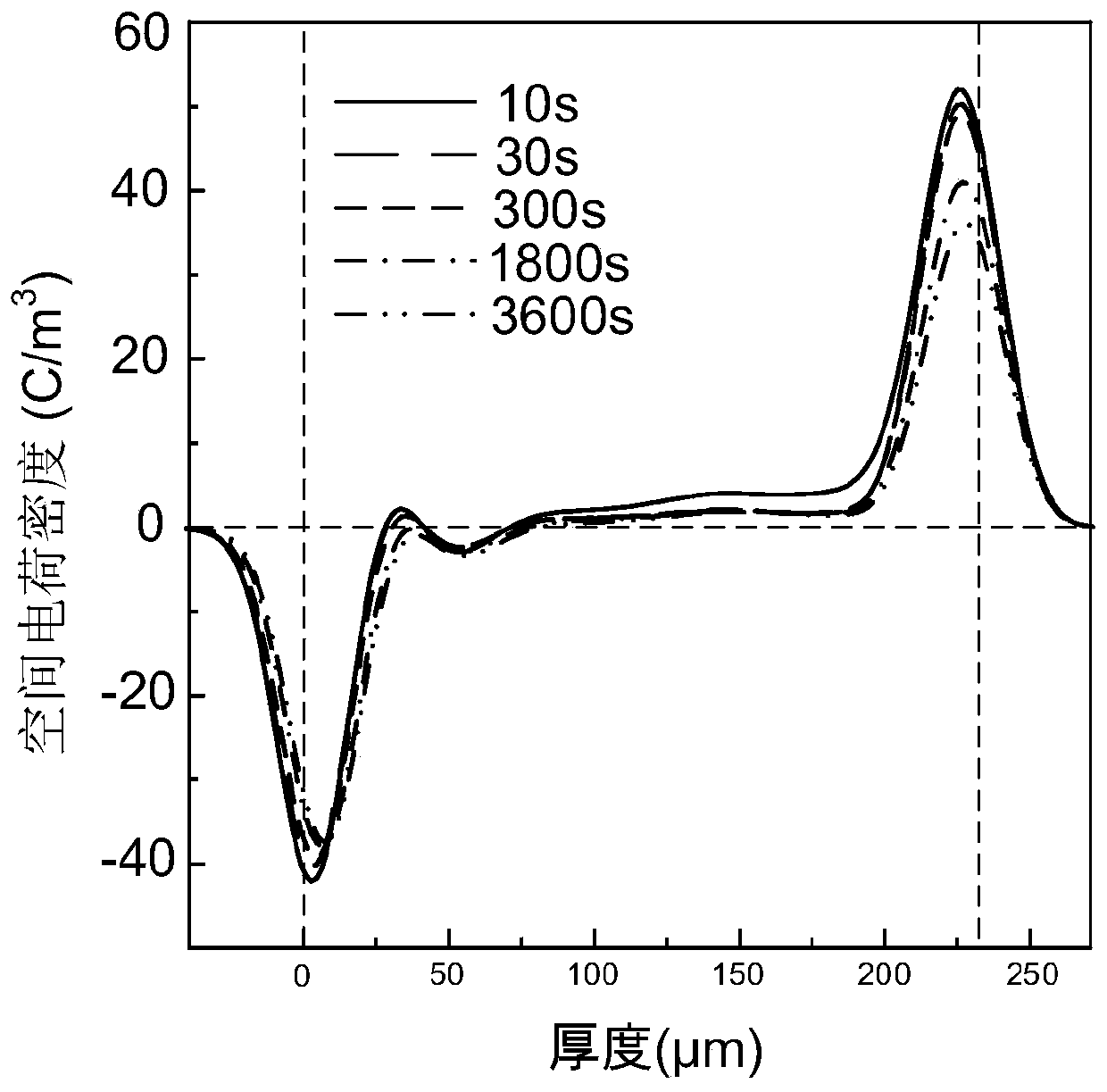

Embodiment 3

[0053] The technical solution adopted in this example is to melt and blend the polypropylene composite base material and the free radical scavenger in the following mass ratio, extrude and granulate to make a polypropylene-based high-voltage DC cable that uses free radicals to improve space charge characteristics Insulation material:

[0054] Polypropylene 85 parts

[0055] Ultra-low density polyethylene 15 parts

[0056] Free radical scavenger 944 0.3 parts

[0057] In this example, a free radical scavenger to improve the space charge characteristics of polypropylene high-voltage DC cable insulation material preparation steps is as follows:

[0058] 1. Fully mix polypropylene, ultra-low density polyethylene, and free radical scavenger according to the following parts by mass to obtain a mixture:

[0059] Polypropylene 85 parts

[0060] Ultra-low density polyethylene 15 parts

[0061] Free radical scavenger 944 0.3 parts;

[0062] 2. Put the mixture obtained in step 1 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com