A kind of nanoparticle type in situ initiator and its preparation method and application

A nanoparticle and initiator technology, applied in the field of nanoparticle type in-situ initiator and its preparation, can solve the problems of high gel rate, insufficient modification effect, and difficulty in uniform dispersion of nanoparticles, so as to improve water resistance and Mechanical strength, the effect of reducing the gelation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

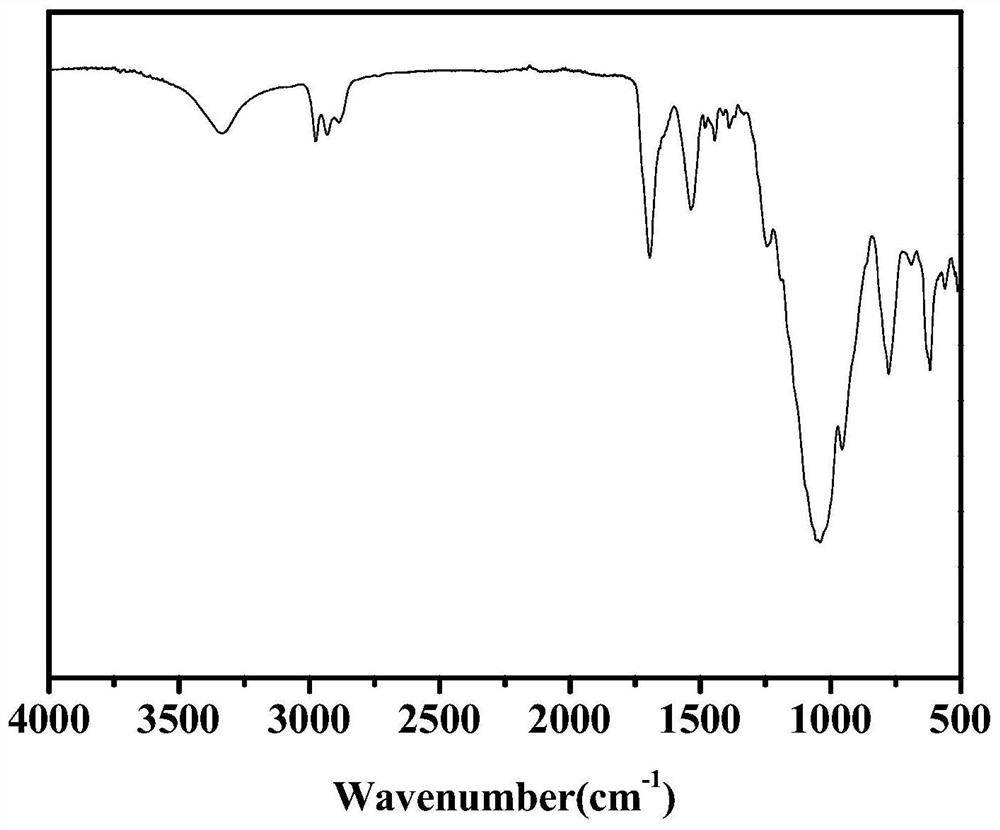

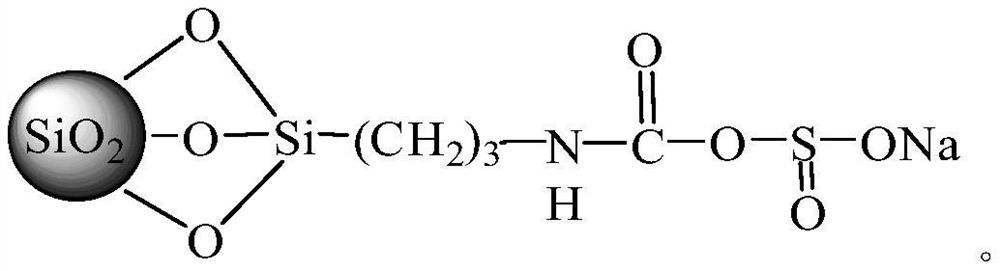

Image

Examples

Embodiment 1

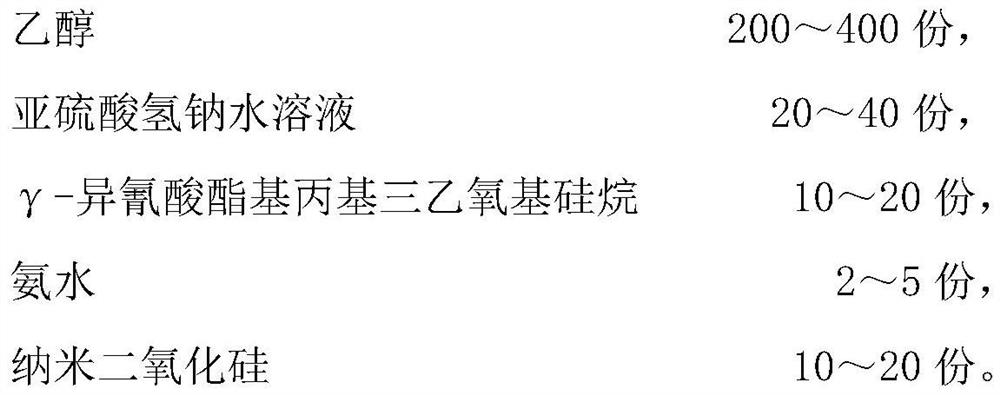

[0020] Under nitrogen protection, 400g of ethanol was added to the reaction vessel, the stirring was started, the temperature was controlled at 15°C, 40g of sodium bisulfite aqueous solution (mass concentration was 25%) was added, and then 20g of γ-isocyanatopropyl triethoxy Silane, reacted for 30 minutes; be warming up to 40 ℃, add 5g ammoniacal liquor (mass concentration is 25%), then add 20g nano-silicon dioxide (particle diameter is 50 nanometers) and react for 3 hours, centrifuge then and wash three times with ethanol, dry to obtain obtained The nanoparticle type in situ initiator described above.

Embodiment 2

[0022] Under nitrogen protection, 300g of ethanol was added to the reaction vessel, the stirring was started, the temperature was controlled to be 25°C, 40g of sodium bisulfite aqueous solution (mass concentration was 25%) was added, and then 20g of γ-isocyanatopropyltriethoxy Silane, reacted for 35 minutes; be warming up to 50 ℃, add 3g ammoniacal liquor (mass concentration is 25%), then add 10g nano-silicon dioxide (particle diameter is 50 nanometers) and react for 4 hours, then centrifuge and rinse with ethanol three times, dry to obtain the The nanoparticle type in situ initiator described above.

Embodiment 3

[0024] Under nitrogen protection, 200g of ethanol was added to the reaction vessel, the stirring was started, the temperature was controlled at 25°C, 30g of sodium bisulfite aqueous solution (mass concentration was 25%) was added, and then 15g of γ-isocyanatopropyltriethoxy Silane was reacted for 30 minutes; the temperature was raised to 50°C, 2g of ammonia (mass concentration was 25%) was added, and 10g of nano silicon dioxide (particle diameter was 20 nanometers) was added for reaction for 2 hours, then centrifuged and washed three times with ethanol, and dried to obtain the The nanoparticle type in situ initiator described above.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com