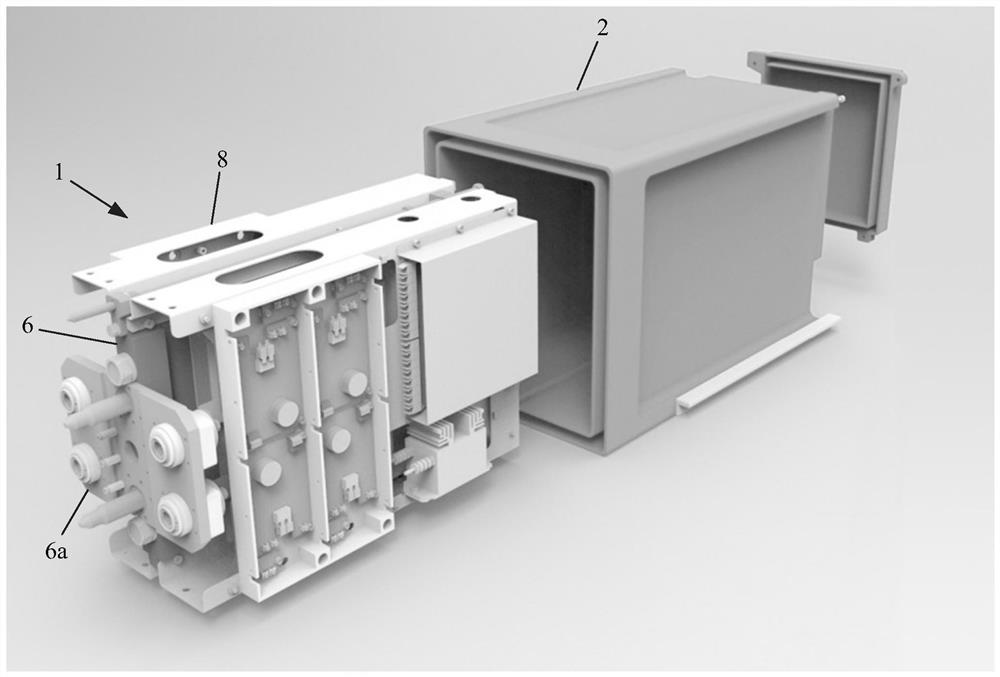

A high-voltage module for power electronic traction transformers

A technology for traction transformers and high-voltage modules, applied in electrical components, printed circuit board sockets, output power conversion devices, etc., can solve the problems of difficult insulation design, reduced weight and volume gains, etc., and achieve a compact overall structure of the module , Simplify the interface design, increase the effect of creepage distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The detailed features and advantages of the present invention are described in detail below in the specific embodiments, the content of which is sufficient to enable any person skilled in the art to understand the technical content of the present invention and implement it accordingly, and according to the specification, claims and drawings disclosed in this specification , those skilled in the art can easily understand the related objects and advantages of the present invention.

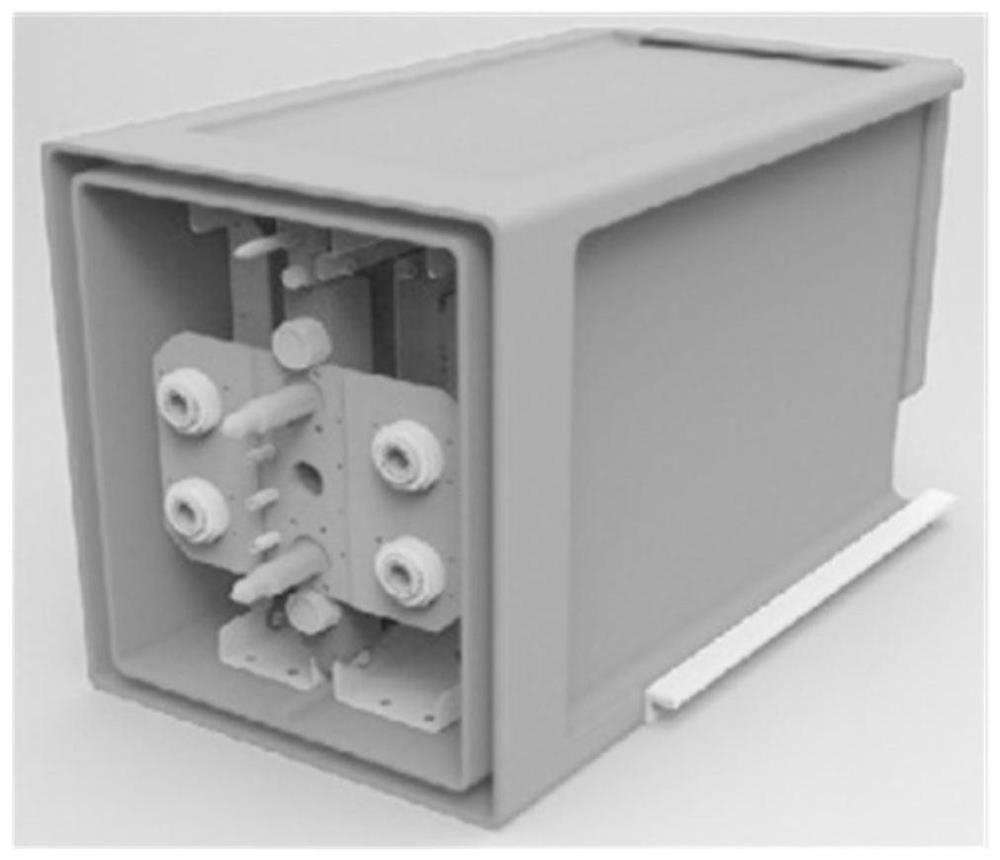

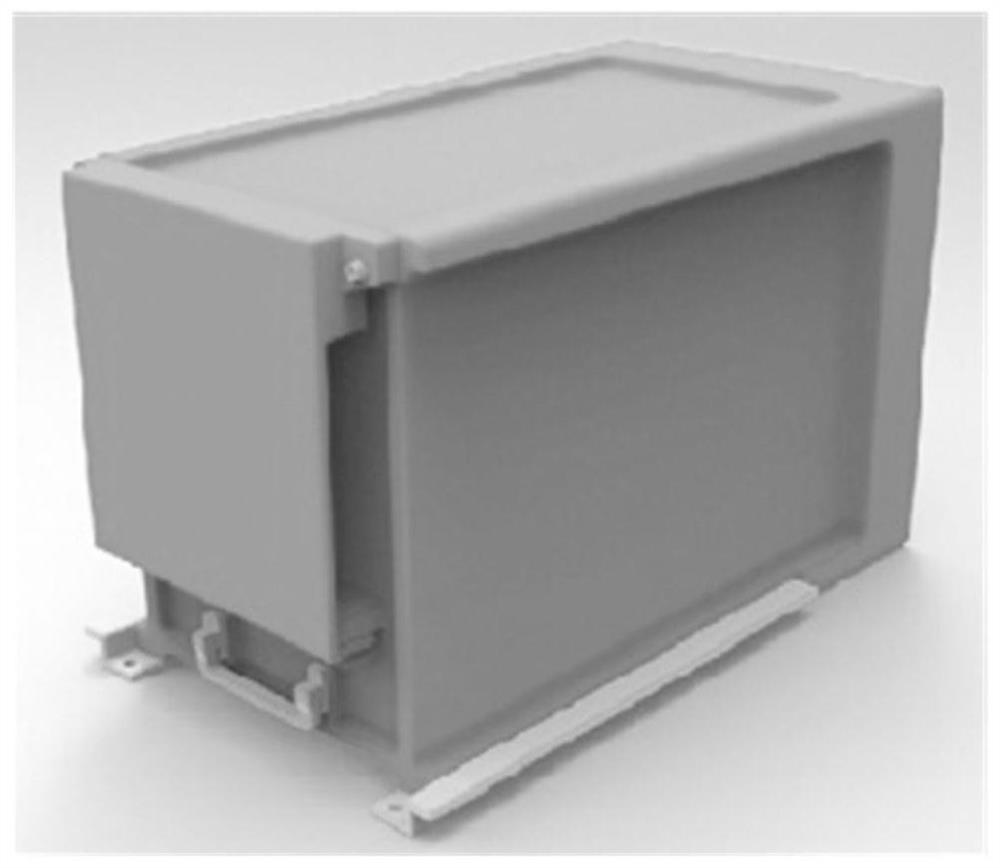

[0051] In the power electronic traction transformer, the front end of the high voltage module is a 25kV power grid cascade, and the rear end is an intermediate isolation transformer, so the voltage of the entire high voltage module is very high relative to the ground. Considering that the PETT device is installed at the bottom of the vehicle, there are strict restrictions on the size of the cabinet and modules, and there is not enough space inside the cabinet to achieve overhead high-voltage i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com