Corrosion evaluation method for scraped car disassembly

A scrapped car and corrosion evaluation technology, applied in geometric CAD and other directions, can solve problems such as function failure, resource waste, car corrosion, etc., achieve significant economic benefits, reduce maintenance costs, and improve anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described below in conjunction with accompanying drawing.

[0049] like figure 1 As shown, a corrosion evaluation method for dismantling of scrapped automobiles, including the following steps:

[0050] (1) Corrosion information collection: collect basic information related to corrosion of scrapped vehicles;

[0051] The basic information related to vehicle corrosion includes service life, mileage, driving conditions, maintenance times and locations, car washing frequency, maintenance frequency, and corrosion environment in the use area, etc., and analyzes corrosion factors and basic corrosion environments.

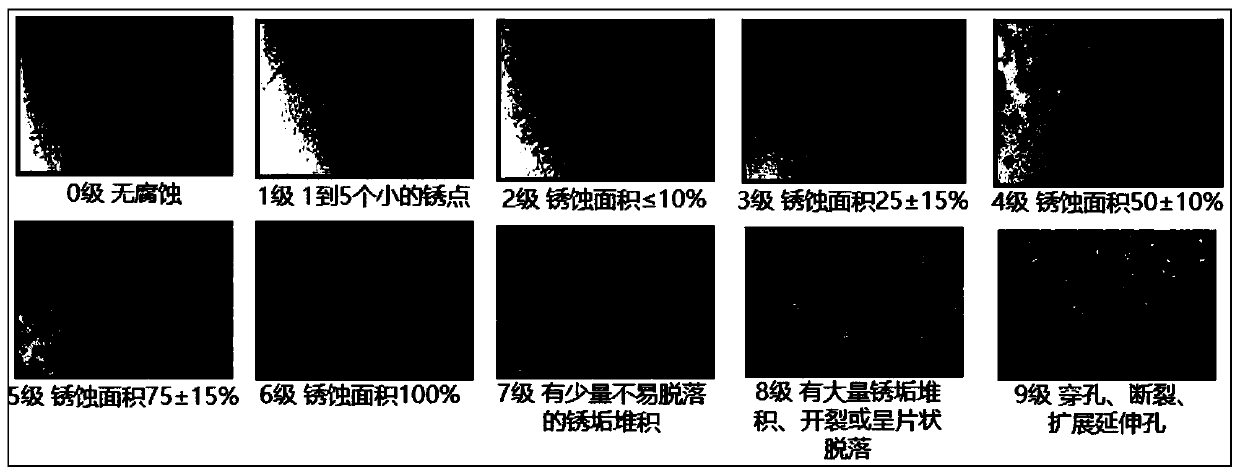

[0052] (2) Pretreatment: Rinse scrapped cars to remove floating rust, mud and foreign matter on the surface, and evaluate the corrosion state of the whole car before dismantling after drying; specifically:

[0053] Use a high-pressure water gun (water pressure of 6Mpa) to wash the outer surface of the body, chassis and engine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com