Multifunctional corrosion ultrahigh-cycle composite fatigue test device

A fatigue test, ultra-high cycle technology, used in measuring devices, weather resistance/light resistance/corrosion resistance, test wear resistance, etc., can solve the problem of single, no salt spray environment and liquid environment, direct and free switching of test devices, etc. , to achieve the effect of good atomization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following examples will describe the present invention in more detail, so that those skilled in the art can better understand the advantages and characteristics of the present invention.

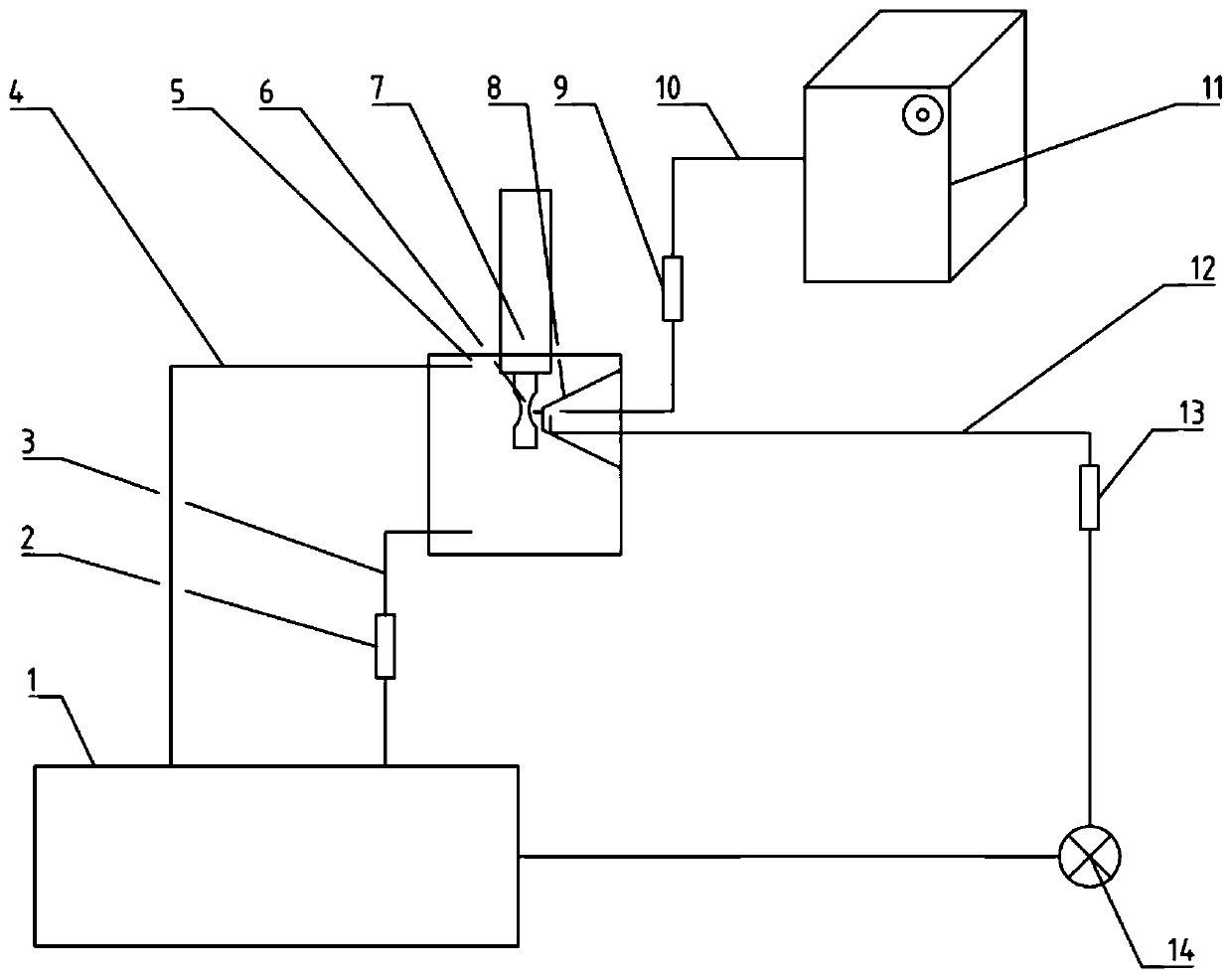

[0020] see figure 1 , a multi-functional corrosion ultra-high cycle composite fatigue test device, including a liquid storage tank 1, a liquid outlet valve 2, a lower liquid outlet pipe 3, an upper liquid outlet pipe 4, an environmental chamber body 5, a fatigue sample 6, an ultrasonic fatigue Test device 7, nozzle 8, air inlet controller 9, air inlet pipe 10, air compressor 11, liquid inlet pipe 12, liquid inlet controller 13, water pump 14, the environment box body 5 passes through the lower liquid outlet pipe 3, the upper outlet The liquid pipe 4 is connected with the liquid storage tank 1 , the nozzle 8 is fixed on the side wall of the environmental box 5 , connected with the water pump 14 through the liquid inlet pipe 12 , and connected with the air compressor 11 through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com