Active chilled beam tail end device and active chilled beam air conditioning system

A terminal device, active technology, applied in air conditioning system, heating method, pipeline arrangement, etc., can solve the problem of easy to wet indoor floor, wet users, etc., to achieve the effect of convenient operation, easy maintenance and improved sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

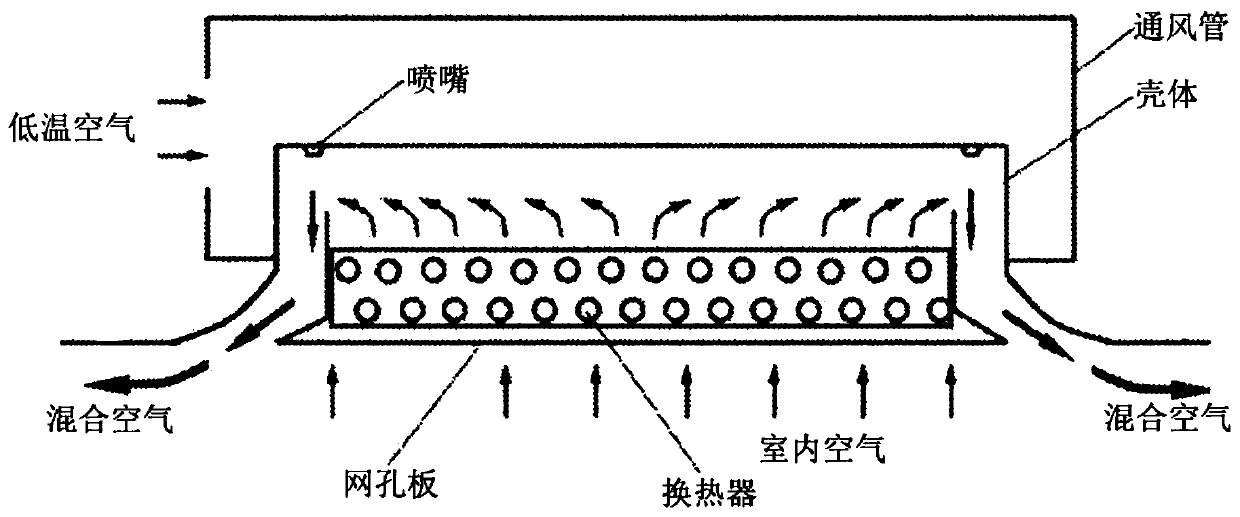

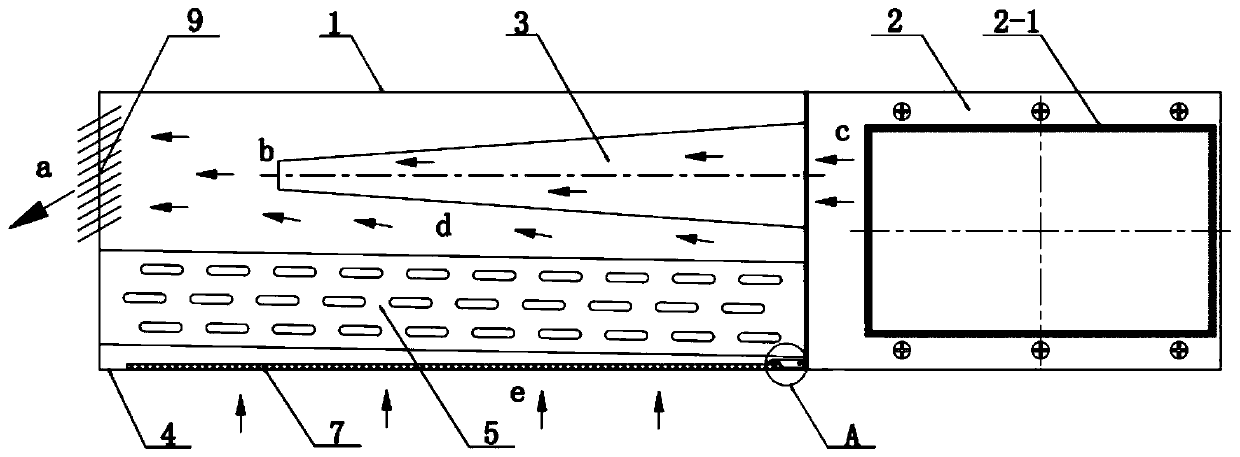

[0032] An active chilled beam end device such as Figure 2-3 As shown, it includes a casing 1, a ventilation pipe 2, a nozzle 3, a mesh plate 4, a heat exchanger 5, a water tray 6, and a filter 7.

[0033] The right end of the housing 1 is provided with an air inlet hole, the left end of the housing 1 is provided with an air outlet hole, the lower end of the housing 1 is provided with a mesh plate installation hole, and the right end of the housing 1 is connected with the ventilation pipe 2 by the fastener. The side walls are fixed together. In the first embodiment, the fasteners are bolts or screws.

[0034] In order to guide the flow direction of the wind, the air outlet of the casing 1 is provided with a plurality of wind deflectors 9 arranged side by side.

[0035] A hinge shaft is provided on the side of the wind deflector 9 close to the housing 1, and the housing 1 is provided with a hinge hole for interference fit with the hinge shaft. With such setting, the user can ...

Embodiment 2

[0049] An active chilled beam air conditioning system, comprising an active chilled beam end device, the active chilled beam end device being the active chilled beam end device. The active chilled beam end device can prevent the condensed water from falling, collect the condensed water, make full use of the cooling capacity of the condensed water, improve the cooling efficiency, and improve the user experience.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com