Stretching auxiliary spraying system for reducing length of waste selvage yarns of air-jet loom

An air-jet loom and waste selvedge yarn technology, which is applied in looms, textiles, textiles and paper making, etc., can solve the problems affecting the efficiency of air-jet looms, the quality of grey fabrics and the increase of waste selvedge yarn loss, etc., so as to ensure the flight distance and time, Reduce the formation of weft shrinkage and ensure the effect of not easy to retract

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

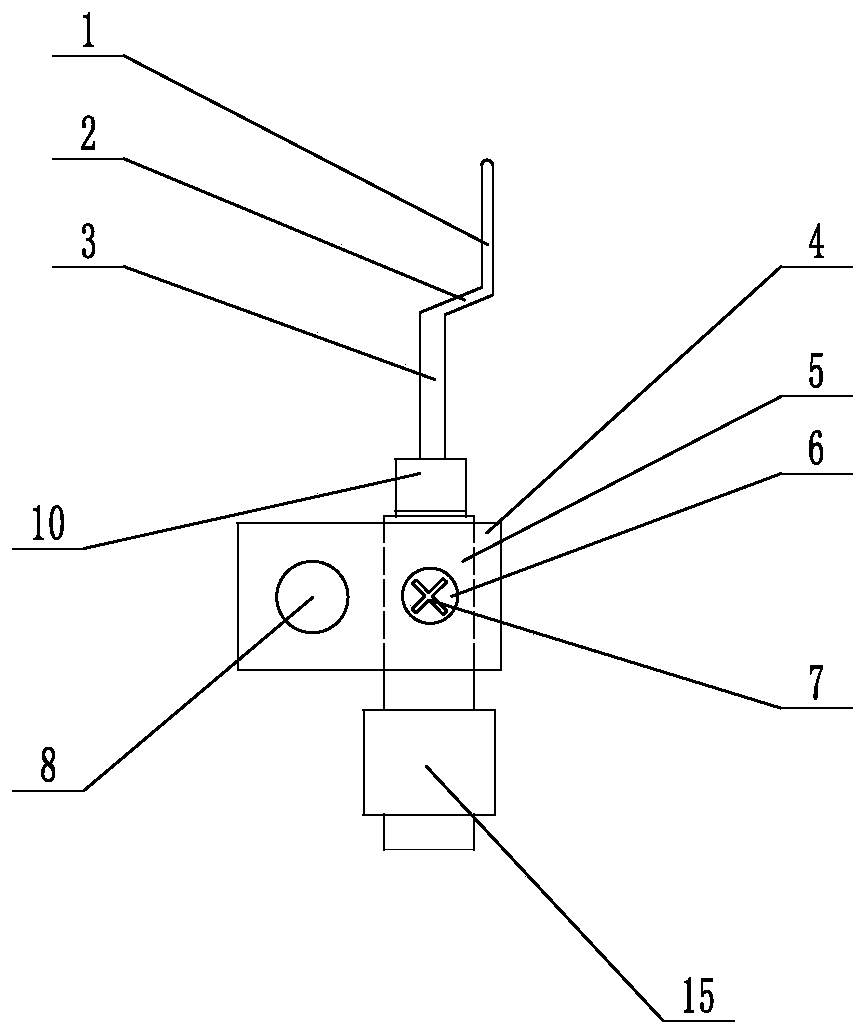

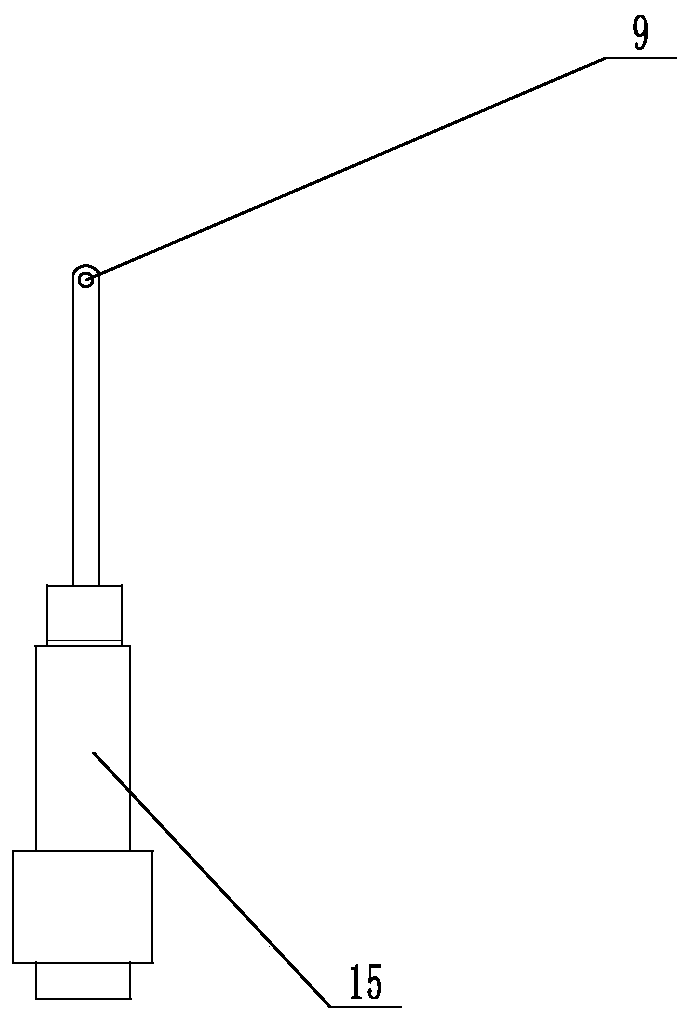

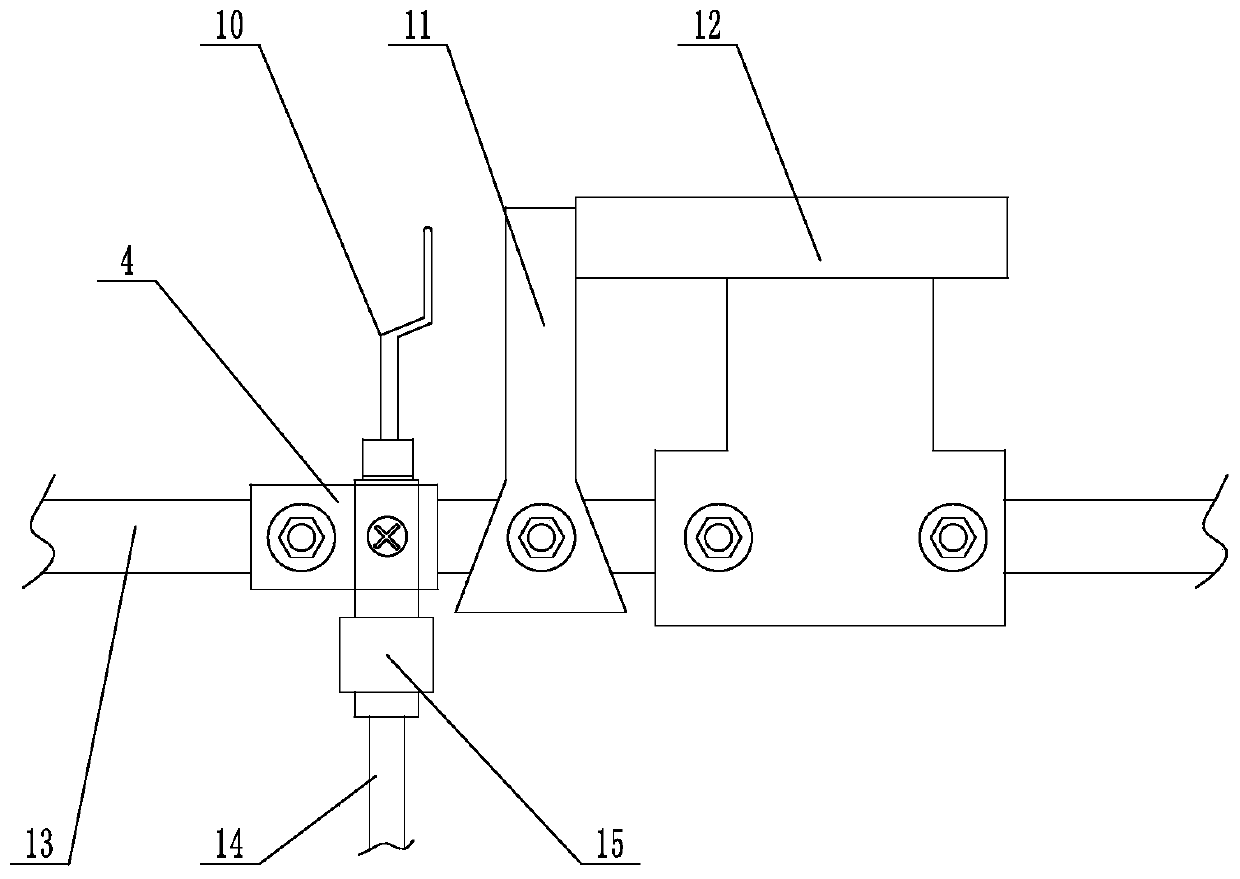

[0021] like Figure 1-3 As shown, the stretching auxiliary spraying system for reducing the length of the waste side yarn of the air-jet loom includes a steel sley 13, on which the auxiliary spraying device 15, the photoelectric weft detecting device 15, and the photoelectric weft detecting device are fixedly arranged in sequence from left to right on the steel sley 13. Head 11 and stretching auxiliary spray channel 12, described auxiliary spray device 15 includes nozzle pipe 10 and base 4, described base 4 is provided with installation hole 5, and described nozzle pipe 10 passes installation hole 5 and is fixed on the base 4, the nozzle 10 is composed of a round pipe 3, a transition pipe 2 and a flat pipe 1 sequentially connected from bottom to top, the flat pipe 1 is vertically arranged with the steel sley 13, and the flat pipe 1 A nozzle 9 is arranged horizontally ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com