Traction device for braiding polyester steel wire filter screen

A pulling device and filter mesh technology, applied in woven fabrics, textiles and papermaking, etc., can solve the problems affecting filter mesh processing efficiency, high strength, and difficulty in controlling the tension of polyester filaments, saving manpower and material resources, ensuring weaving Reasonable effect of quality and structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the objectives, technical solutions, and beneficial effects of the present invention clearer, the preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, and the present invention will be further described to facilitate the understanding of the skilled person.

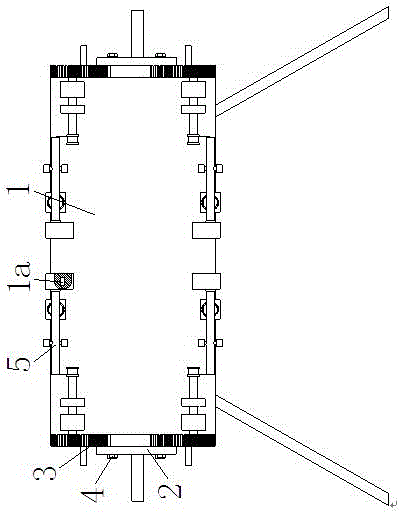

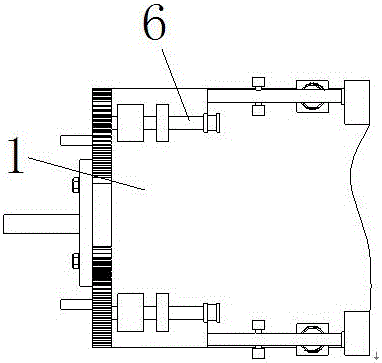

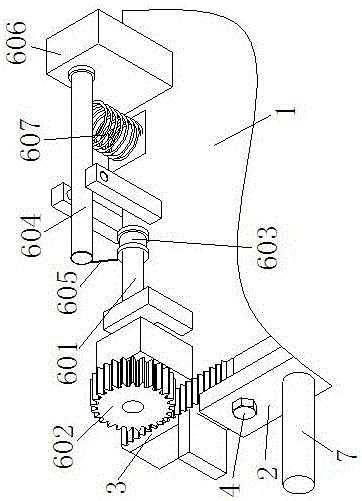

[0018] Such as Figure 1 to Figure 3 As shown, a traction device for weaving a polyester steel wire filter includes a support frame 1. Both the left and right ends of the support frame 1 are equipped with sliding blocks 2 that can move vertically along the support frame 1. The upper and lower ends of the block 2 are equipped with racks 3, and the front end of the support frame 1 is evenly provided with through holes 1a. When in use, the polyester thread can be guided by the through hole 1a.

[0019] A positioning nut 4 is installed on the sliding block 2. When in use, the positioning nut 4 is used to control the position of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com