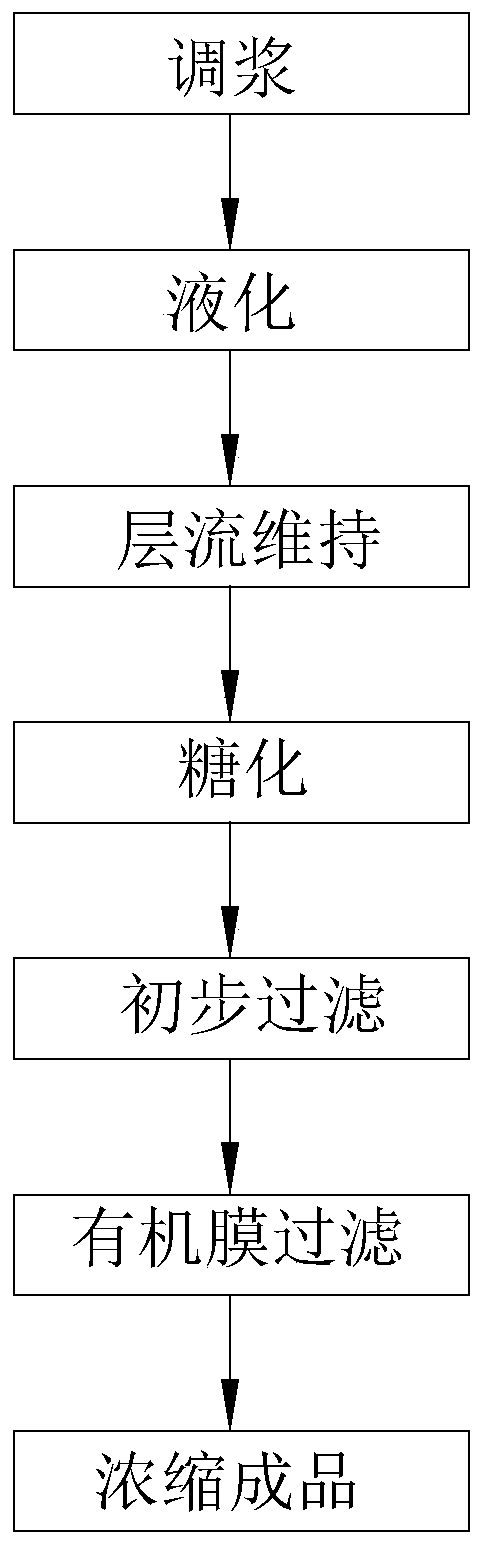

Production process of corn starch syrup

A corn starch and production process technology, applied in the directions of energy input, fermentation, etc., can solve the problems of reduced viscosity, many complex decomposition reactions, insufficient liquefaction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A kind of production technology of cornstarch syrup, specifically comprises the steps:

[0041] Step 1, Slurry: Add the crushed and sieved cornstarch granules and water into the slurry tank at a mass ratio of 1:1, stir well, adjust the pH of the mixed slurry to 5.4 after stirring evenly, and add liquefaction enzyme Stir evenly, the amount of liquefaction enzyme added is 0.005% of the mass of corn starch, the liquefaction enzyme is α-high temperature amylase, raise the temperature of the system to 60°C to obtain corn starch milk, and then transport the corn starch milk to the spray buffer tank for standby ;

[0042] Step 2. Liquefaction: The cornstarch milk is sprayed into the flash tank through the steam liquefaction injector for flash evaporation. The spray temperature is controlled at 103°C, and the spray time is 10 minutes. The temperature of the flash tank is controlled at 95°C through the vacuum cooling system, and the flash The steaming time is 10 minutes, and the ...

Embodiment 2

[0049] A kind of production technology of cornstarch syrup, specifically comprises the steps:

[0050] Step 1. Slurry mixing: crushed and sieved cornstarch granules and water are added to the slurry mixing tank according to the mass ratio of 1:1.2, fully stirred, and after stirring evenly, adjust the pH of the mixed slurry to 5.8, and add liquefaction enzyme Stir evenly. The amount of liquefaction enzyme added is 0.01% of the mass of corn starch. The liquefaction enzyme is α-high temperature amylase. Raise the temperature of the system to 65°C to obtain corn starch milk, and then transport the corn starch milk to the spray buffer tank for standby ;

[0051] Step 2. Liquefaction: The cornstarch milk is sprayed into the flash tank through the steam liquefaction injector for flash evaporation. The injection temperature is controlled at 110°C, and the injection time is 7 minutes. The temperature of the flash tank is controlled at 100°C through the vacuum cooling system, and the fl...

Embodiment 3

[0058] A kind of production technology of cornstarch syrup, specifically comprises the steps:

[0059] Step 1. Slurry mixing: crushed and sieved cornstarch granules and water are added to the slurry mixing tank according to the mass ratio of 1:1.5, fully stirred, and after stirring evenly, adjust the pH of the mixed slurry to 6.1, and add liquefaction enzyme Stir evenly, the amount of liquefaction enzyme added is 0.015% of the mass of corn starch, the liquefaction enzyme is α-high temperature amylase, raise the system temperature to 65°C to obtain corn starch milk, and then transport the corn starch milk to the spray buffer tank for standby ;

[0060] Step 2. Liquefaction: spray the cornstarch milk into the flash tank through the steam liquefaction ejector for flash evaporation. The injection temperature is controlled at 115°C, and the injection time is 5 minutes. The temperature of the flash tank is controlled at 98°C through the vacuum cooling system, and the flash The stea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com