Efficient medicine residue dehydration treatment device

A technology of processing device and dehydration device, applied in cleaning methods and utensils, chemical instruments and methods, climate change adaptation, etc., can solve the problems of small screw extrusion, inability to operate continuously, severe noise equipment, etc. Sustainability, good dewatering effect, high working efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below with reference to the accompanying drawings and embodiments.

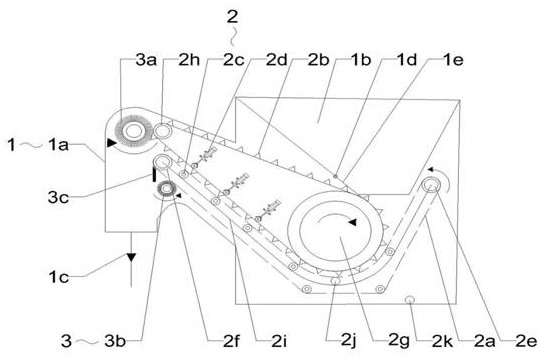

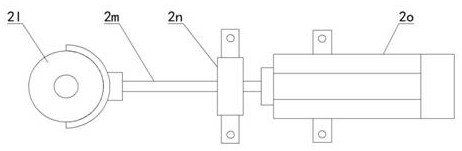

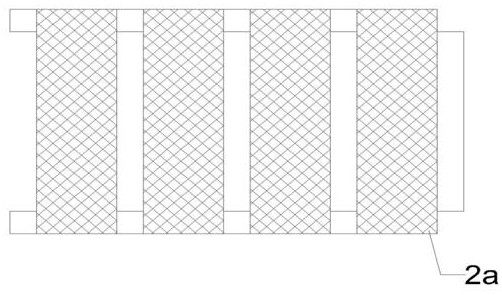

[0023] like Figure 1-4 As shown, a high-efficiency medicinal residue dehydration treatment device includes a feeding device 1 , a dehydrating device 2 and a cleaning device 3 . The feeding device 1 includes a protective cover 1a, a funnel 1b, and a material outlet 1c. The protective cover 1a is a hollow shell, the funnel 1b opens upward and is located above the protective cover 1a, and the material outlet 1c opens downward and is located on the protective cover 1a. Below the cover 1a; the dehydration device 2 is arranged in the inner cavity of the protective cover 1a. The dehydration device 2 includes a filter screen conveyor belt 2a, a toothed conveyor belt 2b, a plurality of support wheels 2c and a plurality of pressure buffers 2d. The extension path of the filter screen conveyor belt 2a is The U-shaped body composed of the hypotenuse sectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com