PET composite material and preparation method thereof, and application of PET composite material

A composite material, ethylene technology, applied in the field of PET composite material and its preparation, can solve the problems of not being able to solve the problem of PET sticking to the mold, the mechanical properties of PET being greatly affected, and the reduction of the cold crystallization temperature being limited, etc., and achieving excellent mechanical mechanics. Performance, mold release effect improvement, crystal perfection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The raw materials for the preparation of the PET composite material in the present invention include 1-3% of ethylene-(meth)acrylate nucleating agent, preferably 2-3%. In the present invention, the ethylene-(meth)acrylate nucleating agent preferably includes ethylene-(meth)acrylate zinc salt, ethylene-(meth)acrylate sodium salt and ethylene-(meth)acrylate lithium salt One or more of them, more preferably ethylene-(meth)acrylic acid sodium salt; in an embodiment of the present invention, the ethylene-(meth)acrylic acid sodium salt is purchased from DuPont, and the specific model is SURLYN8920. The present invention preferably adopts the above-mentioned nucleating agent, which can form ion clusters with PET resin in the melt processing process, and use the ion clusters as nucleation points to form spherulites with uniform size, which is conducive to making the cold crystallization temperature of PET composite materials Moving to the low temperature region, the melting poi...

Embodiment 1

[0052] Dry PET at 1400°C for 5 hours to keep the water content below 0.05%, mix the dried PET with toughening agent, nucleating agent and antioxidant evenly to obtain the first mixed material, and extrude it by twin-screw The main feeding port of the machine is added; the plasticizer and the mineral filler are placed in a high-speed mixer at a speed of 2000r / min, and mixed for 2 minutes. After mixing evenly, cool for 1 hour to obtain the second mixed material, which is produced by a twin-screw extruder Add the modified glass fiber from the second side feed port of the twin-screw extruder, and melt and knead in the twin-screw extruder; after the melting and kneading, the resulting mixed melt Extrude through a twin-screw extruder, then cool, air-dry, pelletize, and dry (dry in a blast oven at 120°C for 5 hours) to obtain a PET composite material;

[0053] Among them, the process parameters of melting and kneading are: the twin-screw extruder is divided into eleven temperature zo...

Embodiment 2~4

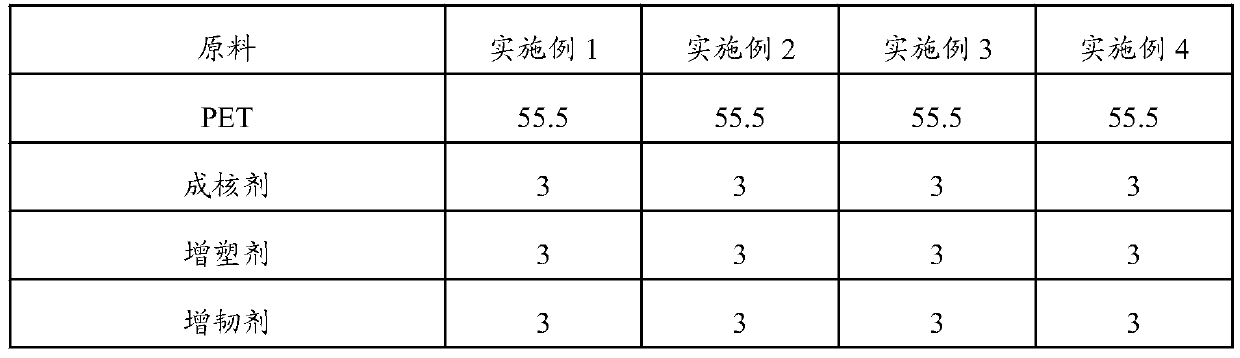

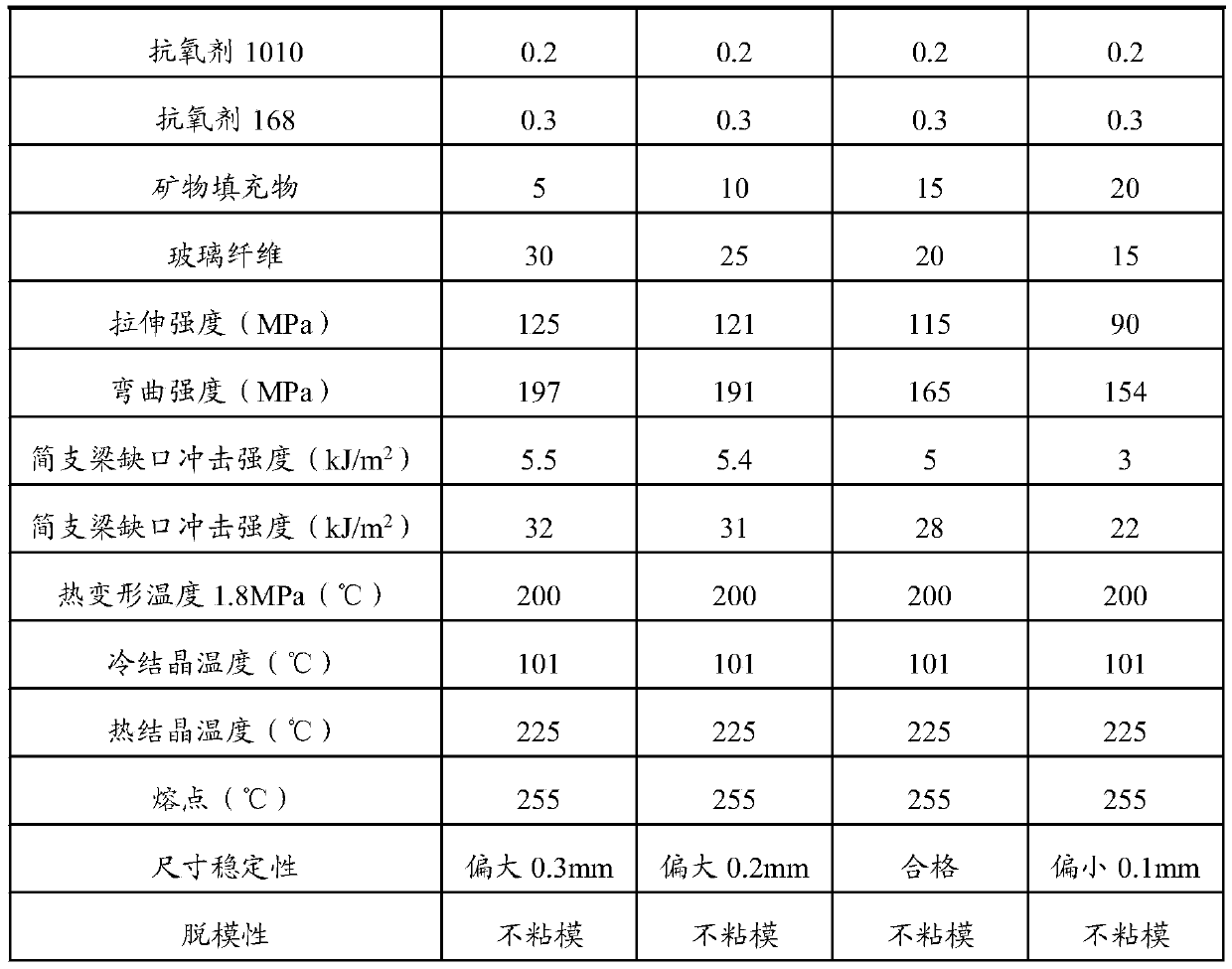

[0056] Referring to the method of Example 1 to prepare PET composite materials, the amount of each preparation raw material is specifically listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com