Extrusion grinding type kitchen waste pulping machine and pulping method thereof

A kitchen waste, extrusion and grinding technology, applied in cocoa, grain processing, food science, etc., can solve the problems of pipe network blockage, small garbage particles, large garbage particles, etc., and achieve the effect of eliminating blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

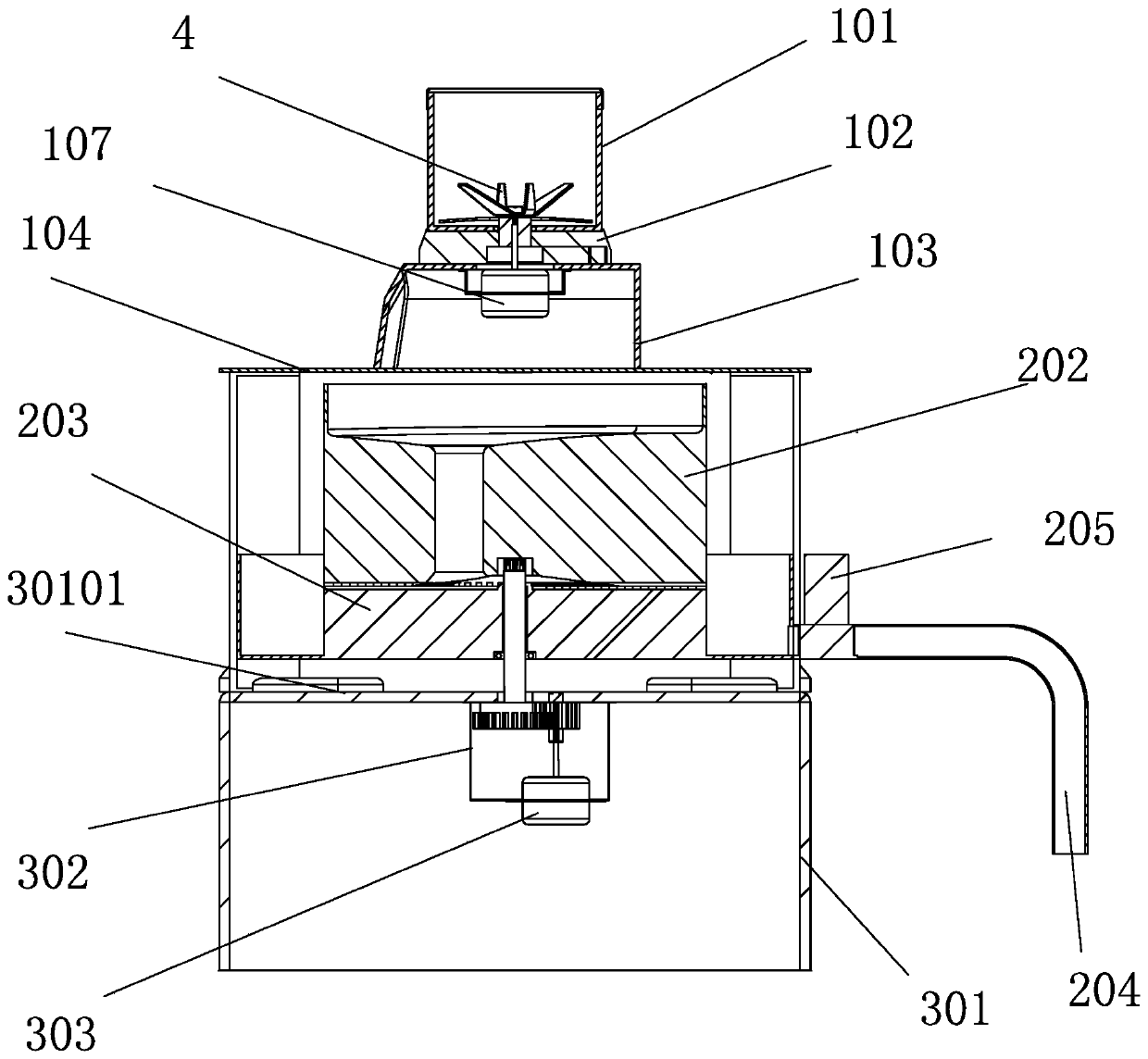

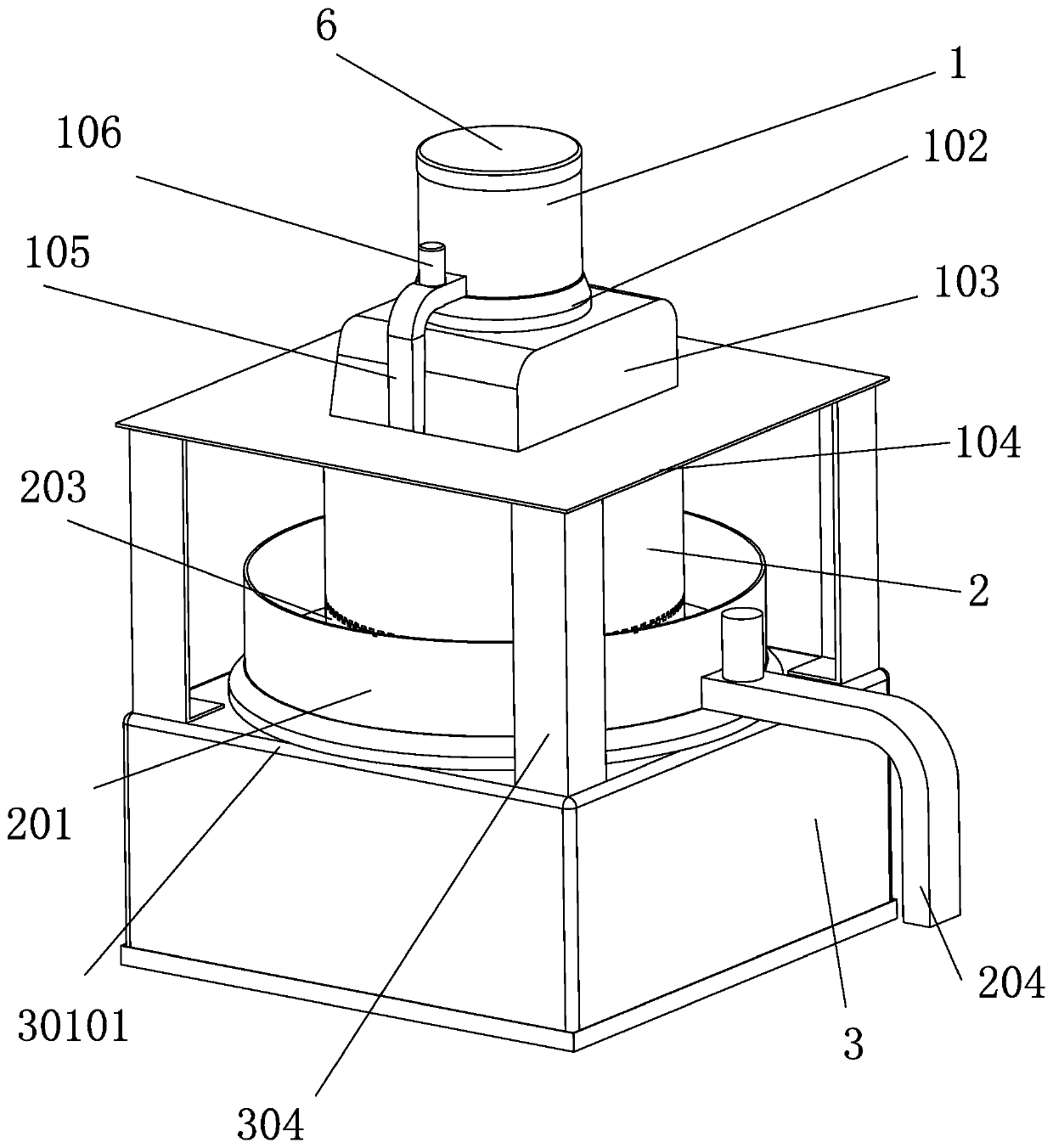

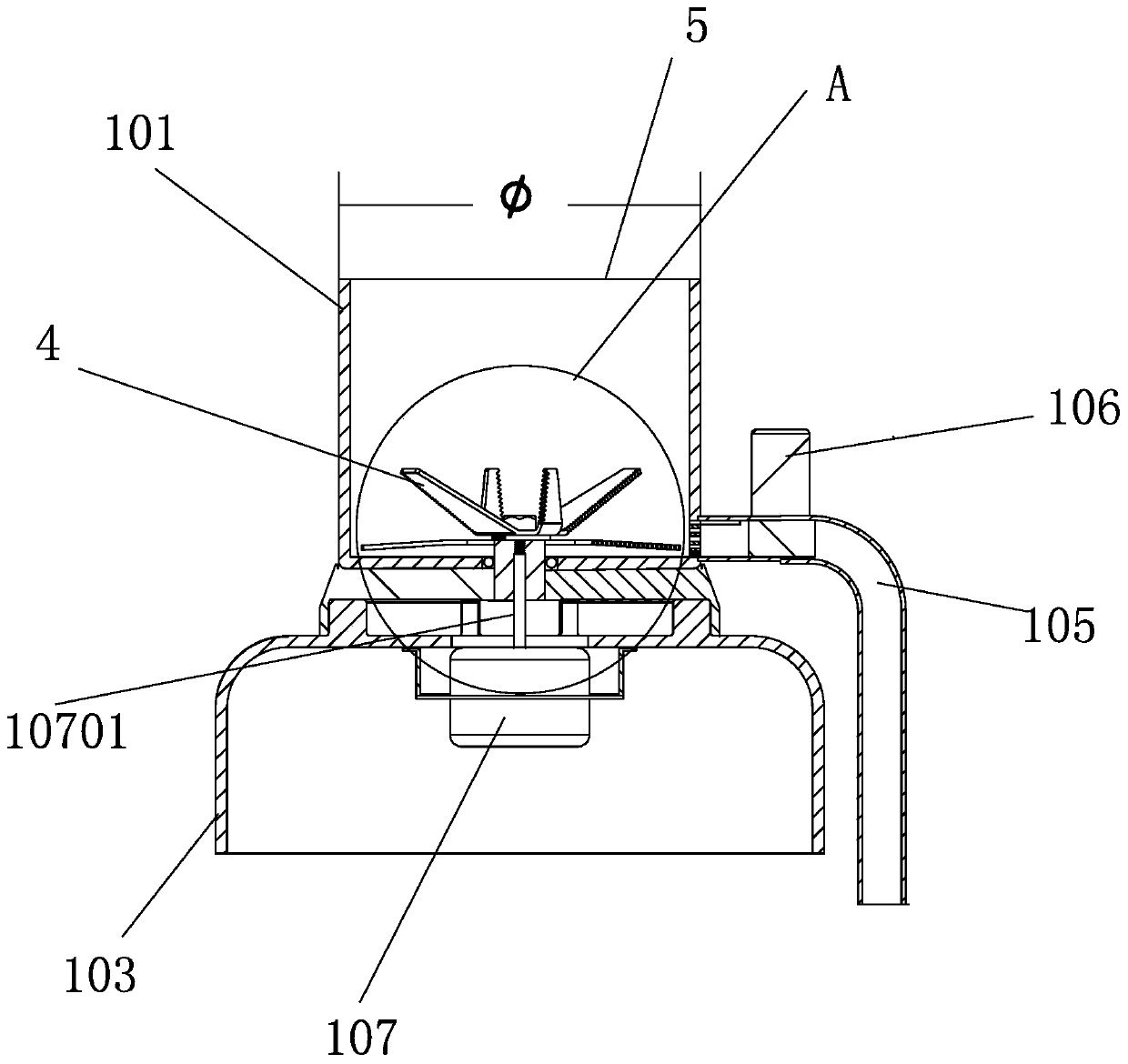

[0060] Such as Figure 1 to Figure 7-3 As shown in Fig. 1 , an extrusion grinding type kitchen waste refiner, the kitchen waste is wet waste, including four categories of vegetable and fruit waste, meat waste, spoiled food, and leftovers produced in the kitchen, of which spoiled food It is unusable waste, and the others are dual classification of usable and unusable;

[0061] Comprising a stirring pulverizer 1, a refiner device 2 and a power system 3 of the refiner device 2; the agitating pulverizer 1 includes a stirring pulverizing cylinder 101, a stirring cylinder seat 102, a stirring motor box 103, a placement plate 104, and a paste discharge Pipe 105 and pasting electromagnetic valve 106, the stirring and pulverizing cylinder 101 is fixedly arranged above the stirring cylinder seat 102, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum width | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com