Method for simulating and measuring thermal migration quantity of formaldehyde and acetaldehyde in cigarette blasting beads to smoke

A measurement method and migration technology, applied in measurement devices, instruments, scientific instruments, etc., can solve problems such as large deviation of measurement results, loss of components to be measured, and influence on analysis results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

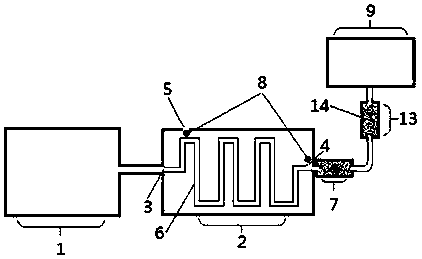

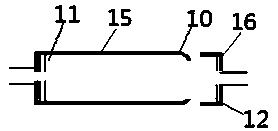

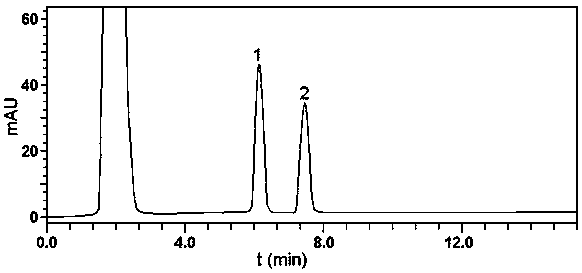

[0097] The popping beads tested are the popping beads samples in which formaldehyde and acetaldehyde are artificially added to the popping bead wall material, and the amount of formaldehyde and acetaldehyde added is 48.2 µ g / g; The ingredient of the popping beads is caprylic capric acid glyceride. The smoking parameters of the smoking machine were the ISO standard suction mode (1 puff every 1 minute, the suction volume of each puff was 35 mL, and the suction duration was 2 seconds), a total of 9 puffs were taken, and the purge air flow was gradually In the heating mode, the airflow temperature of each puff is set with reference to the puff-by-puff temperature (measured by thermocouple) of the smoke flow passing through the bead part when the cigarette is actually burned.

[0098] Take 10 particles (0.22~0.3g) of the popping beads for the test, wrap them with cellulose acetate and crush them, quickly put them into the purge pipe, and connect the various parts of the device with...

Embodiment 2

[0104] The popping beads tested are the popping bead samples artificially added formaldehyde and acetaldehyde to the popping bead core material, and the added amount of formaldehyde and acetaldehyde is 43.8% µ g / g; Bead wrapping ingredients are caprylic capric acid glyceride, formaldehyde and acetaldehyde are added in caprylic capric glyceride. The smoking parameters of the smoking machine were the ISO standard suction mode (1 puff every 1 minute, the suction volume of each puff was 35 mL, and the suction duration was 2 seconds), a total of 9 puffs were taken, and the purge air flow was gradually In the heating mode, the airflow temperature of each puff is set with reference to the puff-by-puff temperature (measured by thermocouple) of the smoke flow passing through the bead part when the cigarette is actually burned.

[0105] Take 10 particles (0.22~0.3 g) of the popping beads for the test, wrap them with cellulose acetate, crush them, put them into the purge tube quickly, an...

Embodiment 3

[0110] The popping beads tested are the popping bead samples artificially added formaldehyde and acetaldehyde to the popping bead core material, and the added amount of formaldehyde and acetaldehyde is 43.8% µ g / g; Bead wrapping ingredients are caprylic capric acid glyceride, formaldehyde and acetaldehyde are added in caprylic capric glyceride. The smoking parameters of the smoking machine were the ISO standard suction mode (1 puff every 1 minute, the suction volume of each puff was 35 mL, and the suction duration was 2 seconds), a total of 9 puffs were taken, and the purge air flow was gradually In the heating mode, the airflow temperature of each puff is set with reference to the puff-by-puff temperature (measured by thermocouple) of the smoke flow passing through the bead part when the cigarette is actually burned.

[0111] Take 10 particles (0.22~0.3 g) of the popping beads for the test, wrap them with cellulose acetate, crush them, put them into the purge tube quickly, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com