Preheater of consumable electrode and crystallizer, heating device and electroslag remelting system

A technology of consumable electrodes and heating devices, which is applied in the field of preheaters and their heating devices, and electroslag remelting systems, and can solve the problem of hydrogen content in pores at the bottom of electroslag ingots, which cannot be effectively eliminated by electroslag remelting systems. Problems such as electrode surface and crystallizer, to achieve the effect of reducing hydrogen content, reducing porosity, and reducing moisture content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

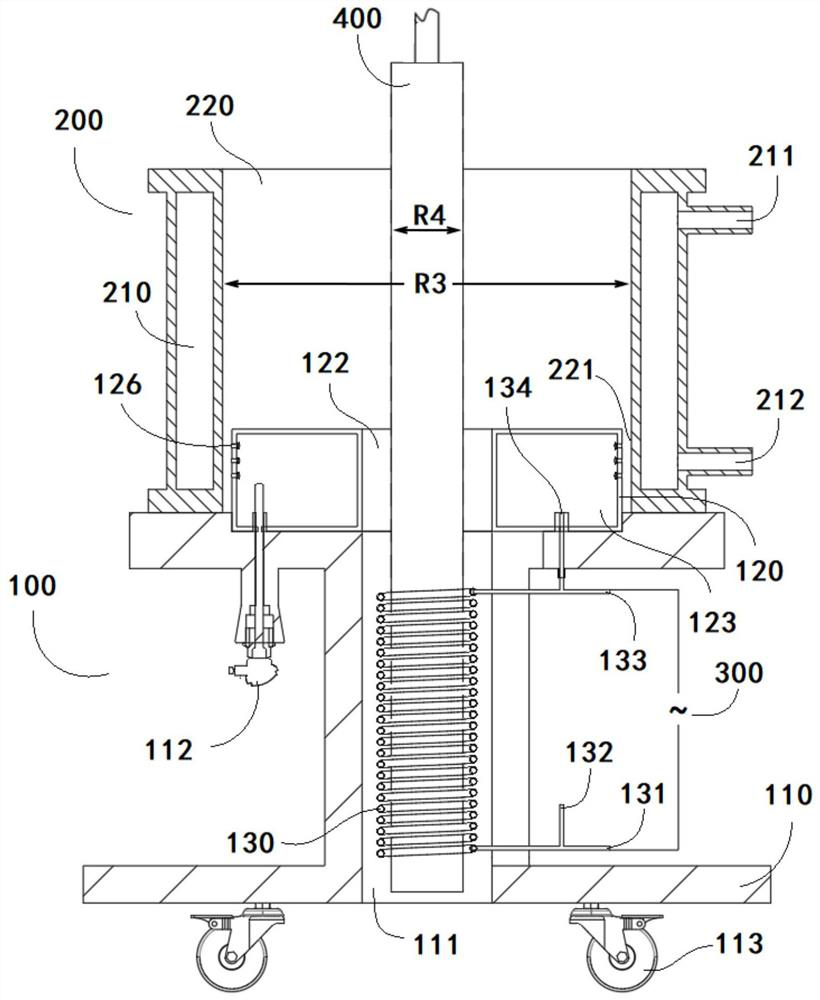

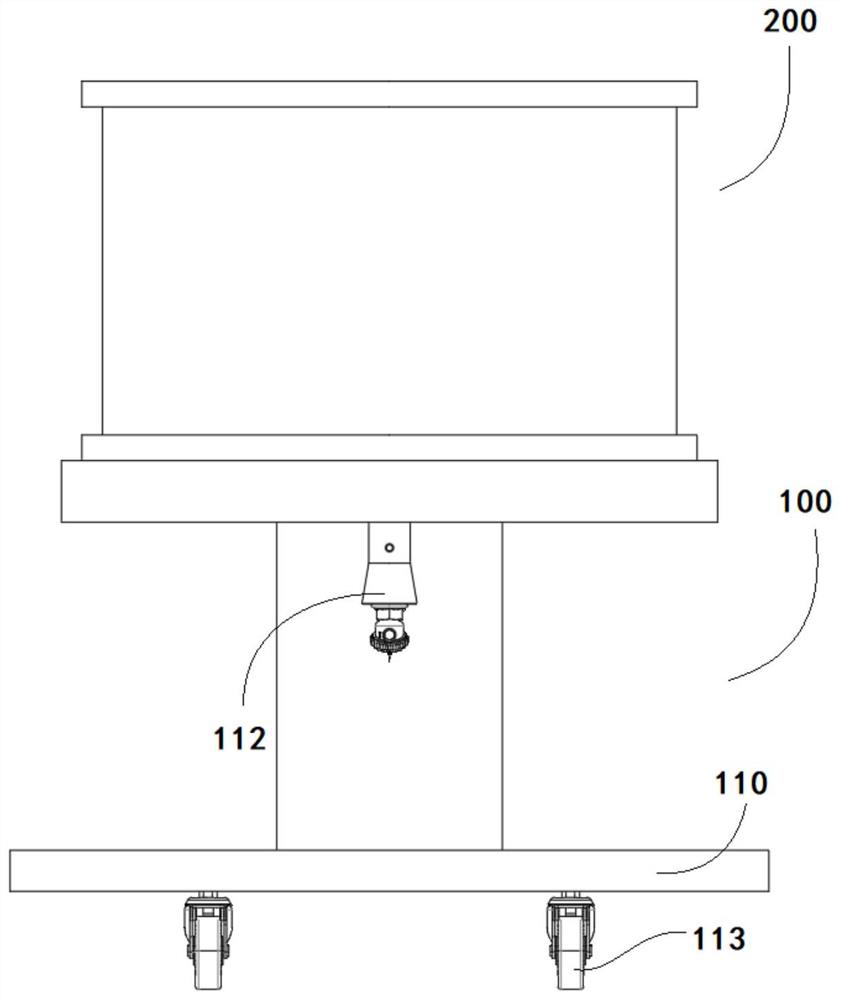

[0047] This embodiment provides an electroslag remelting system, such as Figure 7 As shown, it includes a consumable electrode 400 , a heating device 100 , a crystallizer 200 , a protective cover 500 and a bottom water tank 600 . When preheating the consumable electrode 400 and the crystallizer 200 before electroslag remelting, the crystallizer 200 is arranged on the heating device 100, and the second heater 120 is located at the bottom of the inner wall 221 of the crystallizer, The consumable electrode 400 is passed through the heating device 100 and the crystallizer 200 for heating. During electroslag remelting, the preheated consumable electrode 400 and the crystallizer 200, as well as the protective cover 500 and the bottom water tank 600 are used to start solid slag.

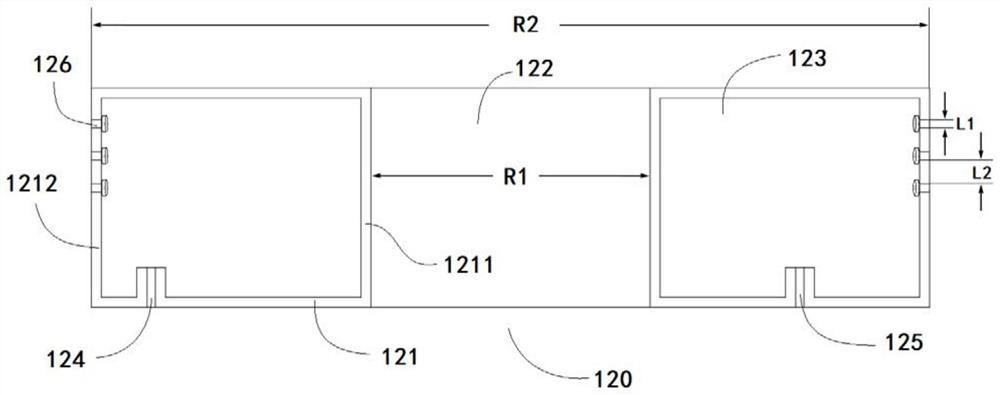

[0048] In the above electroslag remelting system, the diameter of the consumable electrode 400 in this embodiment is R4=500mm; figure 1 As shown, the crystallizer 200 includes a crystallization chamber 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com