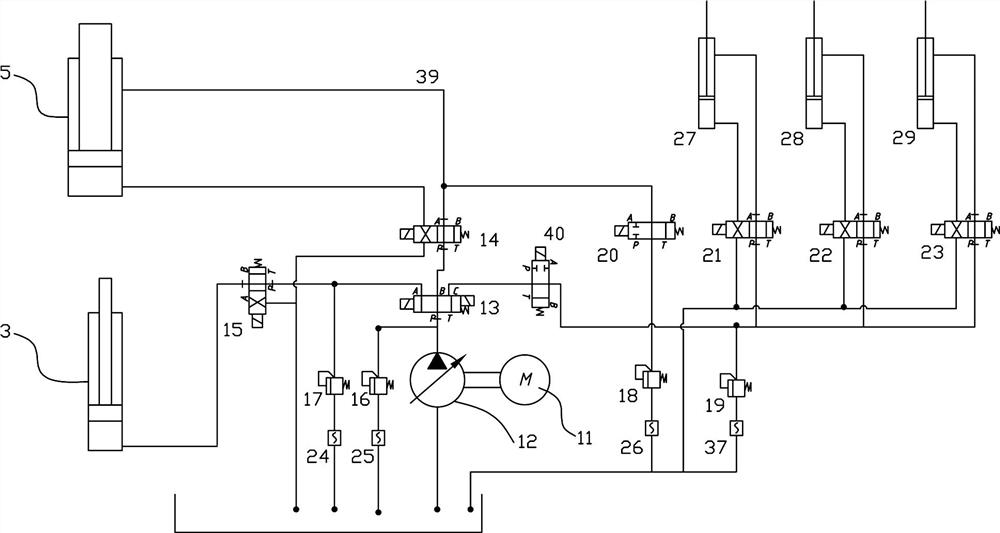

Hydraulic control system and control method of fully automatic hydraulic oil press

A hydraulic control system and hydraulic oil pressing technology, which are applied to the components of fluid pressure actuation systems, presses, manufacturing tools, etc., can solve the problems of undocumented hydraulic control diagrams, error-prone operation by workers, and inconvenience in taking out the pressed cake, etc. The effect of reduced mechanical labor, low cost and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

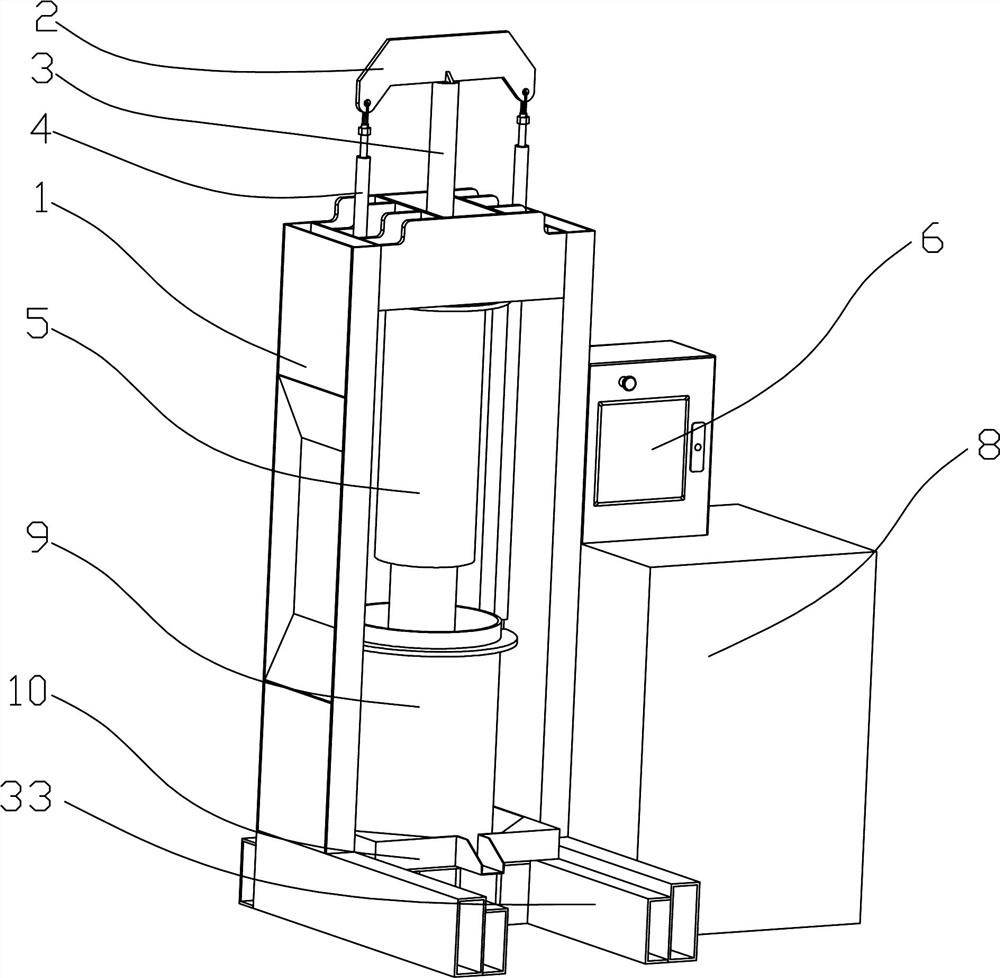

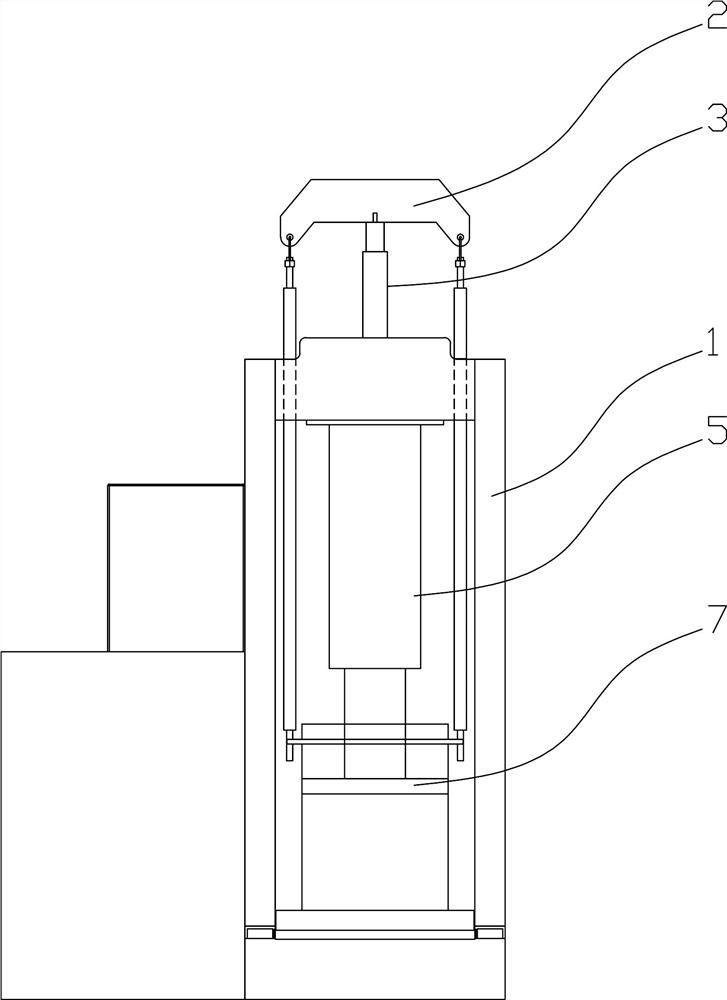

[0056] like Figure 2~7 Among them, a fully automatic hydraulic oil press has the following structure: it includes a frame 1, a vertically installed main hydraulic cylinder 5 is arranged in the frame 1, and a through-structure material barrel 9 is arranged below the main hydraulic cylinder 5, and the material barrel 9 is provided with a pressure head 7 sliding along the inner wall of the material barrel 9, the pressure head 7 is connected with the main hydraulic cylinder 5, an oil receiving pan 10 is arranged at the bottom of the material barrel 9, and a lifting hydraulic pressure is also fixed on the frame 1. Cylinder 3, the lifting hydraulic cylinder 3 is connected with the material barrel 9 through the boom 4, so as to lift the material barrel 9 after the oil pressing is completed, so as to facilitate the extraction of the pressed cake;

[0057] The oil receiving pan 10 is slidably connected to the base chute 33, and the unloading driving cylinder 27 is arranged between the...

Embodiment 2

[0094] On the basis of embodiment 1, a kind of automatic control method that adopts above-mentioned automatic hydraulic oil press hydraulic control system comprises the following steps:

[0095] S01. Control the first switch valve 13 to supply oil to the first switch valve 14, and the first switch valve 14 switches to supply oil to the lower cavity of the main hydraulic cylinder 5, so that the pressure head 7 is lifted; preferably the second switch valve It is also possible for the valve 20 to be in a conducting state, but also to be in a non-conducting state.

[0096] S02, the first switching valve 13 is switched to supply oil to the third switching valve 40, the third switching valve 40 is opened, the fourth switching valve 22 is straight through, and the piston rod of the feeding tank drive cylinder 28 is stretched out, so that the rotating feeding tank 34 Rotate to the top of the barrel 9, the fourth reversing valve 22 to the cut-off position;

[0097] The fifth reversing v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com