Sketch paper papermaking process

A technology for crafting and sketching, which is applied in the field of papermaking craftsmanship of sketching paper, can solve the problems of undisclosed bulk thickness and strength index of paper, affecting sketching effect, and easy to lose powder and hair on the surface of paper, so as to achieve good effect of pencil writing and lead. Good surface texture and good hand feel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

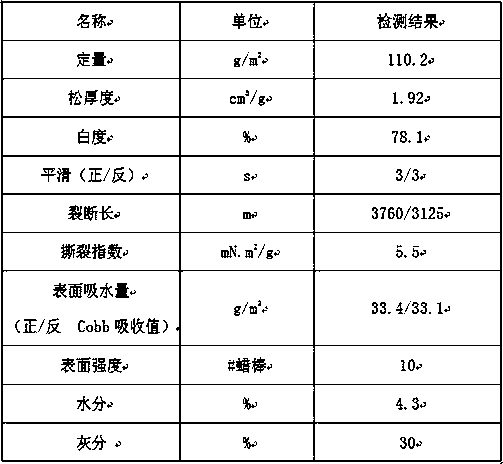

Embodiment 1

[0027] Embodiment 1 A kind of sketch paper papermaking process

[0028] The production steps include: pulping, mixing pulp, pressing, dehydration and drying, preparation of surface glue, sizing, post-drying, and cutting. The specific steps are as follows:

[0029] 1. Pulping

[0030] (1) Preparation of softwood pulp: the bleached kraft softwood pulp with a fiber length of 2.52mm and an ISO brightness of 87% is pulverized by a hydraulic pulper, transferred to the knocking pool, and passed through two φ508 double disc mills Beater, and controlled beating power is 120kwh, beating concentration is 4.2%, beating degree is 22 ° SR, transfers to coniferous wood knocking pool, makes coniferous wood pulp;

[0031] (2) Preparation of chemical-mechanical pulp: crush the chemical-mechanical pulp with a fiber length of 0.81mm and an ISO whiteness of 75% through a hydraulic pulper, transfer it to the knocking pool, and pass through a φ508 double-disc mill beater , without pressing knife, ...

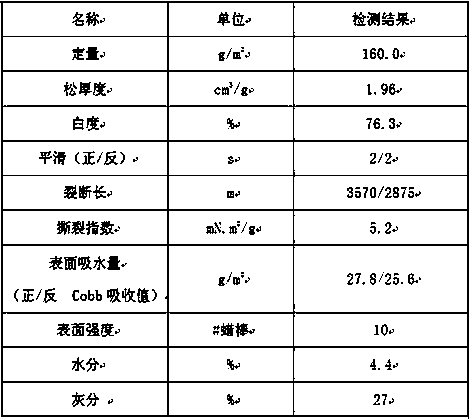

Embodiment 2

[0053] Embodiment 2 A kind of sketch paper making process

[0054] 1. Pulping

[0055](1) Preparation of softwood pulp: Bleached kraft softwood pulp with a fiber length of 2.55mm and an ISO brightness of 86% was pulverized by a hydraulic pulper, transferred to the knocking pool, and passed through two φ508 double disc mills Beater, and control beating power is 120kwh, beating concentration is 4.4%, beating degree is 23 ° SR, transfers to coniferous wood knocking pool, makes coniferous wood pulp;

[0056] (2) Preparation of chemical-mechanical pulp: the chemical-mechanical pulp with a fiber length of 0.88mm and an ISO whiteness of 75% is pulverized by a hydraulic pulper, transferred to the knocking pool, and passed through a φ508 double-disc mill beater , without pressing knife, the beating concentration is 4.0%, the beating degree is 23 ° SR, without fiber bundles, it is transferred to the pool after knocking, and the chemical-mechanical pulp slurry is obtained;

[0057] 2. ...

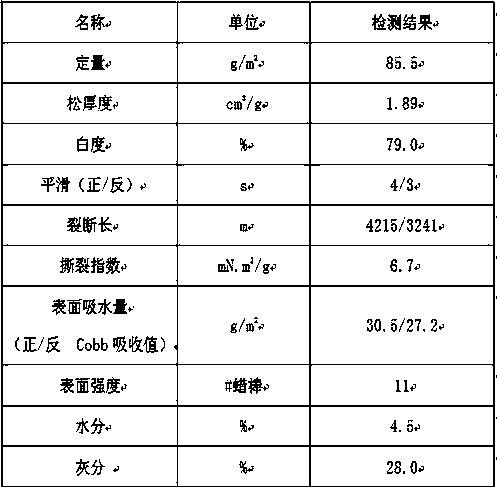

Embodiment 3

[0077] Embodiment 3 A kind of sketch paper making process

[0078] 1. Pulping

[0079] (1) Preparation of softwood pulp: Bleached kraft softwood pulp with a fiber length of 2.55mm and an ISO brightness of 86% was pulverized by a hydraulic pulper, transferred to the knocking pool, and passed through two φ508 double disc mills Beater, and controlled beating power is 120kwh, beating concentration is 4.4%, beating degree is 21 ° SR, transfers to coniferous wood knocking pool, makes coniferous wood pulp;

[0080] (2) Preparation of chemical-mechanical pulp: the chemical-mechanical pulp with a fiber length of 0.8mm and an ISO whiteness of 75% is pulverized by a hydraulic pulper, transferred to the knocking pool, and passed through a φ508 double-disc mill beater , without pressing knife, the beating concentration is 4.0%, the beating degree is 21 ° SR, without fiber bundles, it is transferred to the pool after knocking, and the chemical mechanical pulp slurry is obtained;

[0081] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com