Multi-set-gear-shaped diamond saw blade self-formed by orderly positioning and weakening of carcasses and manufacturing process of saw blade

A diamond saw blade and manufacturing process technology, used in manufacturing tools, metal sawing equipment, metal processing equipment, etc., can solve the problems of high resistance, high energy consumption, low efficiency, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

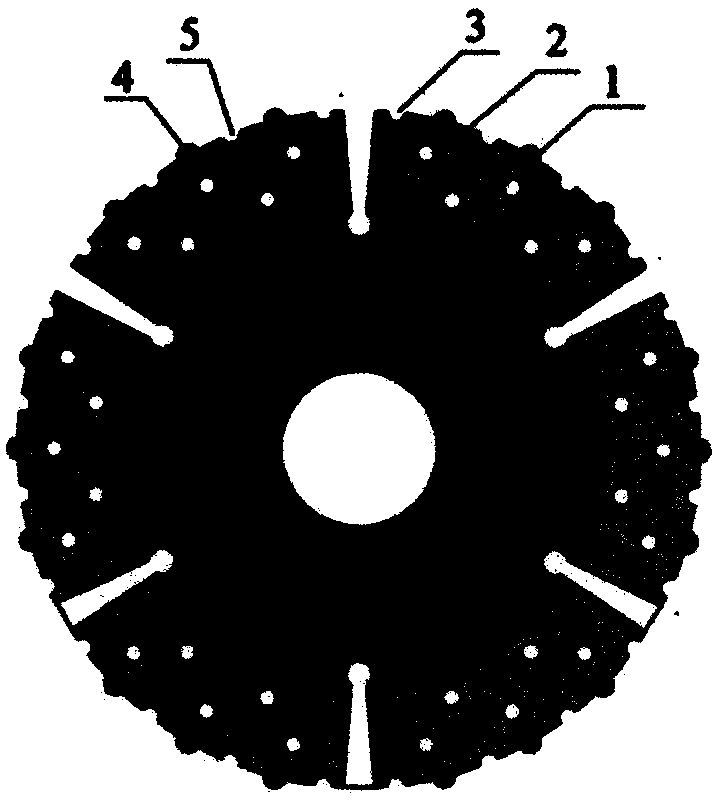

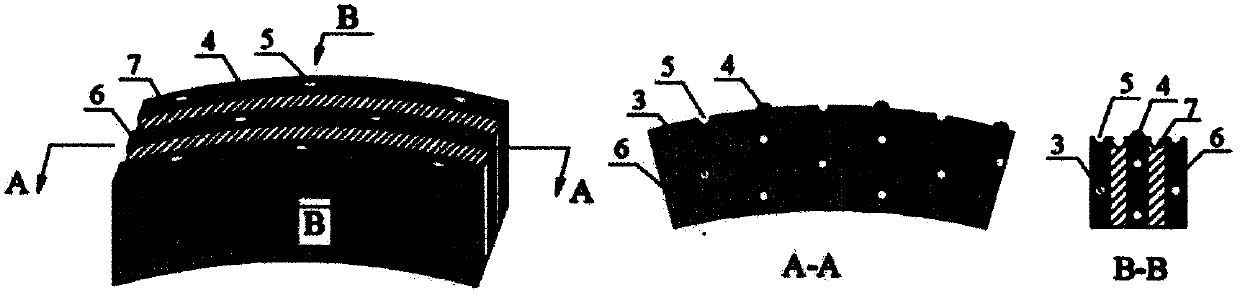

[0016] refer to figure 1 , figure 2 The weakened carcass is positioned in an orderly manner to form multiple groups of gear-shaped diamond saw blades, including the saw blade matrix 1 and the nodes 2. The segment 2 is formed by sintering the working layer sheet 6 and the intermediate layer sheet 7, and the working layer sheet 6 is distributed with weakened carcass particles 3 arranged in an orderly manner. After sharpening and working saw blade, diamond particles 4 protrude from the edge, the weakened carcass particles automatically fall off and pits 5 appear, the intermediate layer 7 is worn out in advance to form grooves, and the saw blade automatically forms multiple sets of gear-shaped working surfaces. The diameter of the saw blade is Φ500mm, the size of the working layer in the block: length × height × thickness = 40mm × 10mm × 0.3mm; the size of the interlayer sheet: length × height × thickness = 40mm × 10mm × 0.2mm, each segment contains 7 layers of working layers a...

Embodiment 2

[0029] refer to figure 1 , figure 2 The weakened carcass is positioned in an orderly manner to form multiple groups of gear-shaped diamond saw blades, including the saw blade matrix 1 and the nodes 2. The segment 2 is formed by sintering the working layer sheet 6 and the intermediate layer sheet 7, and the working layer sheet 6 is distributed with weakened carcass particles 3 arranged in an orderly manner. After sharpening and working saw blade, diamond particles 4 protrude from the edge, the weakened carcass particles automatically fall off and pits 5 appear, the intermediate layer 7 is worn out in advance to form grooves, and the saw blade automatically forms multiple sets of gear-shaped working surfaces. The diameter of the saw blade is Φ1600mm, and the size of the working layer in the block: length × height × thickness = 24mm × 12mm × 0.4mm; the size of the interlayer sheet: length × height × thickness = 24mm × 12mm × 0.2mm, each segment contains 17 layers of working la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com