Corrosion-resisting anchor part, prestress anchor combination part and wind power supporting structure

A technology for corroding anchors and bolts, which is applied in the direction of basic structure engineering, bolts, connecting components, etc., can solve the problems of poor adhesion between heat shrinkable sleeves and anchor bolts, affecting the service life of anchor bolts, and anticorrosion failure of heat shrinkable sleeves. , to achieve the effect of ensuring the effect of pressing and bonding, avoiding uneven thickness and shortening the process of covering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0087] A method for preparing an anti-corrosion anchor bolt, specifically comprising the steps of:

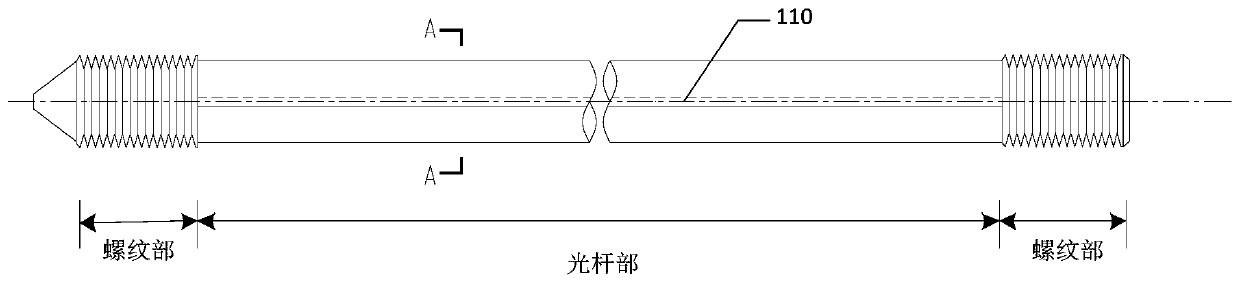

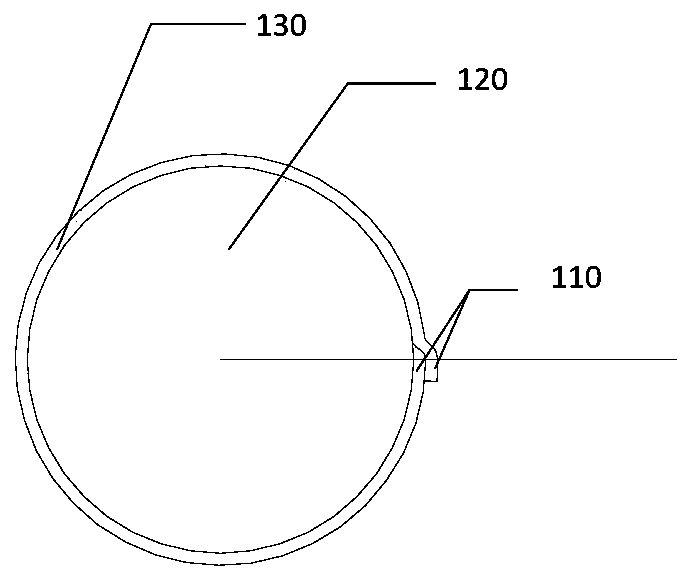

[0088] (1) Provide 20 anchor bolts of M48-8.8 grade (straightness ≤ 2mm / m, bending degree ≤ 0.1% within the total length range), as the anchor bolt body 120, and provide 1000-hour salt spray test at the same time The anchor bolt sample (hereinafter referred to as the anchor bolt body); the anchor bolt body 120 includes a polished rod part and a threaded part arranged at both ends of the polished rod part;

[0089] (2a) coating the outside of the polished rod with the lubricating oil remaining in the machining process, and removing the excess lubricating oil;

[0090] (2b) After the anchor bolt body 120 is heated from room temperature to 250°C at a rate of 13-17°C / min, it is kept for 20 minutes, then naturally cooled to room temperature, and then baked to obtain a dry film protection of the outer surface of the anchor bolt. Floor;

[0091] (2) Provide a polymer butyl self-adhe...

Embodiment 2~6

[0096] The difference with embodiment 1 is only that the width of the strip-shaped overlapping portion is 5mm (embodiment 2), 10mm (embodiment 3), 25mm (embodiment 4), 2mm (embodiment 5), 30mm ( Example 6). After testing, the results show that the number of leaks in the first inspection of the 20 anchor bolts in Examples 2 to 4 is 0, and the number of defects such as hollowing, warping, and wrinkles is 0; the first inspection of the 20 anchor bolts in Example 5 The number of leaks is 1, and the number of defects such as hollowing, warping, and wrinkles is 0; the number of leaks in the first detection of 20 anchor bolts in Example 6 is 0, and the number of defects such as hollowing, warping, and wrinkles is 0. is 1.

Embodiment 7~10

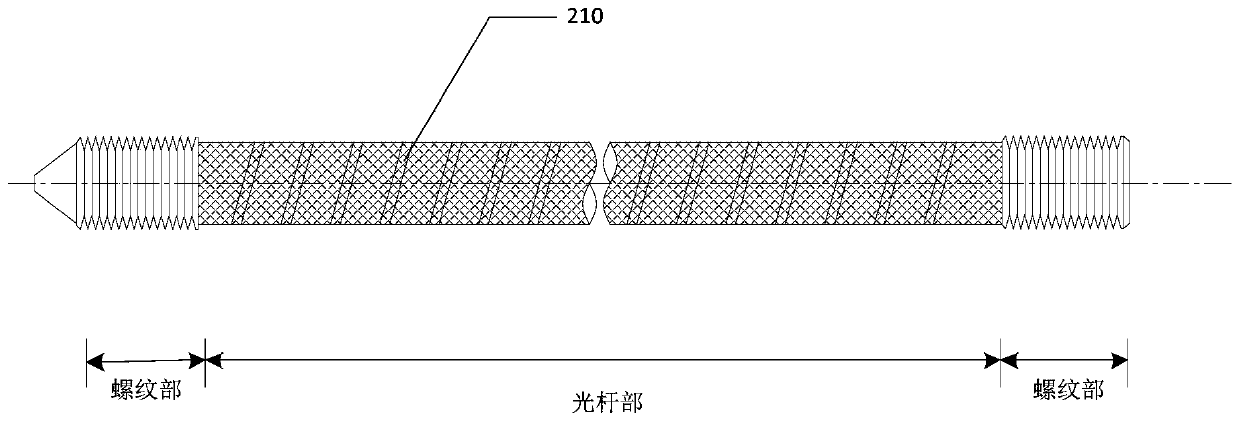

[0098] The only difference from Example 1 is that the thickness of the anti-corrosion coating layer is 0.5mm (Example 7), 2.5mm (Example 8), 0.4mm (Example 9), and 2.7mm (Example 10). After testing, the results show that the number of leaks in the first inspection of the 20 anchor bolts in Examples 7 to 8 is 0, and the number of defects such as hollowing, warping, and wrinkles is 0; The number of leaking points is 1, and the number of defects such as hollowing, warping, and wrinkles is 2; the number of leaking points in the first inspection of the 20 anchor bolts in Example 10 is 0, and the number of defects such as hollowing, warping, and wrinkles is 2. is 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com