Preparation method for extracting glycyrrhizic acid by coupling liquid nitrogen and high-pressure homogenization

A technology of high-pressure homogenization method and high-pressure homogenizer, which is applied to the preparation of sugar derivatives, chemical instruments and methods, steroids, etc., can solve the problems of backward in-depth research on refined processing and comprehensive utilization, insufficient utilization of licorice resources, Affecting the development of licorice industry and other issues, to achieve the effect of ensuring the product's fineness, color and fragrance are completely preserved, and the total extraction time is short

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

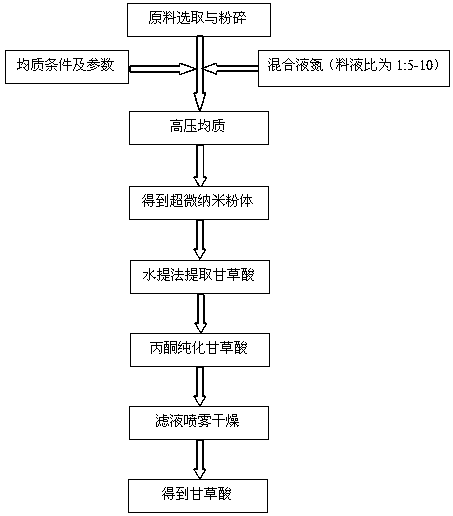

Method used

Image

Examples

Embodiment 1

[0021] Pre-treatment of raw materials: licorice raw materials must be free from diseases and insect pests, and the residual amount of pesticide components does not exceed the national standard. In order to avoid the average time in the high-pressure homogenizer being too long, the raw materials must be preliminarily crushed and passed through a 100-mesh sieve.

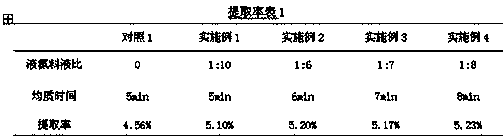

[0022] Micronization of raw materials: Mix the crushed and sieved dry powder with liquid nitrogen at a material-to-liquid ratio of 1:10, and then quickly enter the high-pressure homogenizer for micronization treatment. The pressure of the homogenizer is 100Mpa, and the homogenization time is 5min. , The average power is 50KW.

[0023] Active ingredient extraction: Take the above-mentioned licorice powder of a certain quality and put it into an enamel reaction kettle, add water at a material-to-liquid ratio of 1:6, slowly heat to 100°C, stir and extract for 2 hours, and then filter. Add water to the filter residue and e...

Embodiment 2

[0029] Pre-treatment of raw materials: licorice raw materials must be free from diseases and insect pests, and the residual amount of pesticide components does not exceed the national standard. In order to avoid the average time in the high-pressure homogenizer being too long, the raw materials must be preliminarily crushed and passed through a 100-mesh sieve.

[0030] Micronization of raw materials: The crushed and sieved dry powder is mixed with liquid nitrogen at a material-to-liquid ratio of 1:6, and then quickly enters a high-pressure homogenizer for micronization treatment. The pressure of the homogenizer is 100Mpa, and the homogenization time is 6 minutes. , The average power is 50KW.

[0031] Active ingredient extraction: Take the above-mentioned licorice powder of a certain quality and put it into an enamel reaction kettle, add water at a material-to-liquid ratio of 1:6, slowly heat to 100°C, stir and extract for 2 hours, and then filter. Add water to the filter resid...

Embodiment 3

[0037] Pre-treatment of raw materials: licorice raw materials must be free from diseases and insect pests, and the residual amount of pesticide components does not exceed the national standard. In order to avoid the average time in the high-pressure homogenizer being too long, the raw materials must be preliminarily crushed and passed through a 100-mesh sieve.

[0038] Micronization of raw materials: Mix the crushed and sieved dry powder with liquid nitrogen at a material-to-liquid ratio of 1:7, and then quickly enter the high-pressure homogenizer for micronization treatment. The pressure of the homogenizer is 100Mpa, and the homogenization time is 7 minutes. , The average power is 50KW.

[0039] Active ingredient extraction: Take the above-mentioned licorice powder of a certain quality and put it into an enamel reaction kettle, add water at a material-to-liquid ratio of 1:6, slowly heat to 100°C, stir and extract for 2 hours, and then filter. Add water to the filter residue a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com