Preparation method of NbB6 nanoparticles

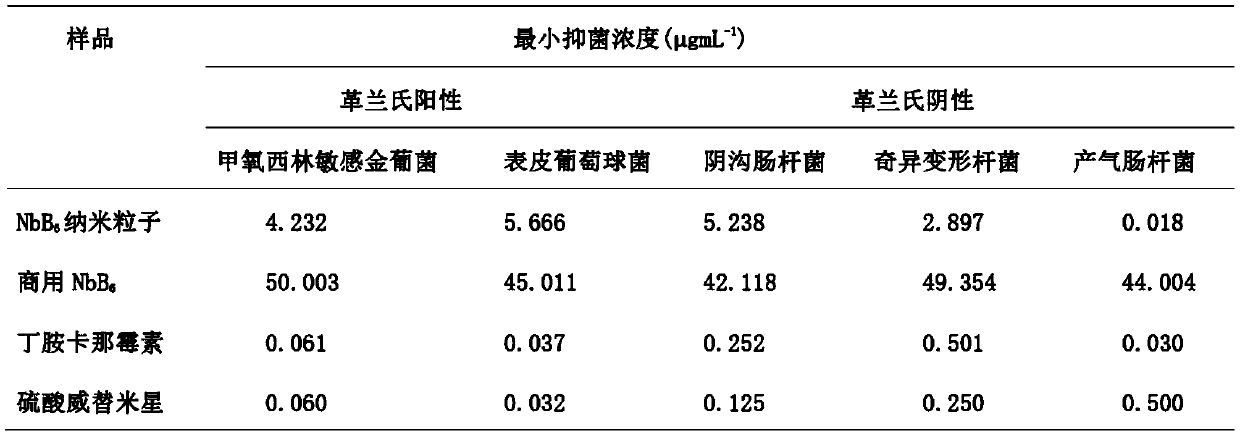

A nanoparticle and ionic liquid technology, applied in the field of advanced nanomaterial preparation, can solve the problems of time-consuming and energy consumption, and achieve the effects of large specific surface area, strong antibacterial activity, and excellent activity of Enterobacter aerogenes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) 2mmolNbCl 3 Add 30 mL of 1-butyl-3-methylimidazolium dicyanamide salt ionic liquid, and stir for 27 minutes under the protection of argon to form a solution;

[0025] (2) Transfer the mixed solution of step (1) to a 50mL reactor under the protection of argon, and feed borane to make borane and NbCl 3 The mol ratio is 9:1, airtight reactor;

[0026] (3) Turn on the liquid phase plasma, the power is 900W, and the mixed solution in the reaction kettle of step (2) is treated at room temperature for 60min to obtain NbB 6 Crude nanoparticles;

[0027] (4) Wash the product three times with deionized water, then three times with absolute ethanol, and dry it for later use.

Embodiment 2

[0029] (1) 2mmolNbCl 3 Add 30 mL of 1-butyl-3-methylimidazolium dicyanamide salt ionic liquid, and stir for 27 minutes under the protection of argon to form a solution;

[0030] (2) Transfer the mixed solution of step (1) to a 50mL reactor under the protection of argon, and feed borane to make borane and NbCl 3 The mol ratio is 9:1, airtight reactor;

[0031] (3) Turn on the liquid phase plasma, the power is 1000W, and the mixed solution in the reaction kettle of step (2) is treated at room temperature for 60min to obtain NbB 6 Crude nanoparticles;

[0032] (4) Wash the product three times with deionized water, then three times with absolute ethanol, and dry it for later use.

Embodiment 3

[0034] (1) 2mmolNbCl 3 Add 30 mL of 1-butyl-3-methylimidazolium dicyanamide salt ionic liquid, and stir for 27 minutes under the protection of argon to form a solution;

[0035] (2) Transfer the mixed solution of step (1) to a 50mL reactor under the protection of argon, and feed borane to make borane and NbCl 3 The mol ratio is 9:1, airtight reactor;

[0036] (3) Turn on the liquid-phase plasma with a power of 800W, and process the mixed solution in the reactor in step (2) for 60 minutes at room temperature to obtain NbB 6 Crude nanoparticles;

[0037] (4) Wash the product three times with deionized water, then three times with absolute ethanol, and dry it for later use.

[0038] NbB of the present invention 6 Properties of Nanoparticles:

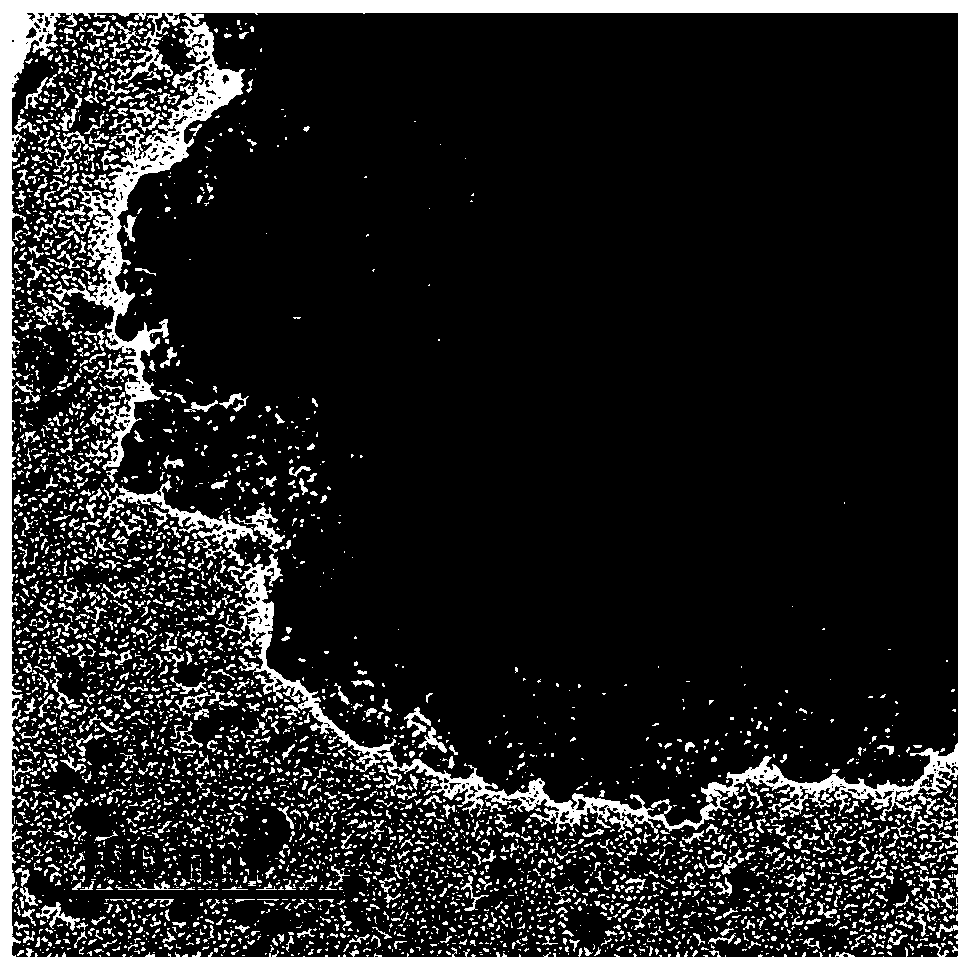

[0039] The sample prepared in Example 1 was characterized by TEM, figure 1 TEM image of the sample. from figure 1 It can be seen that the average particle size of the sample is about 15nm.

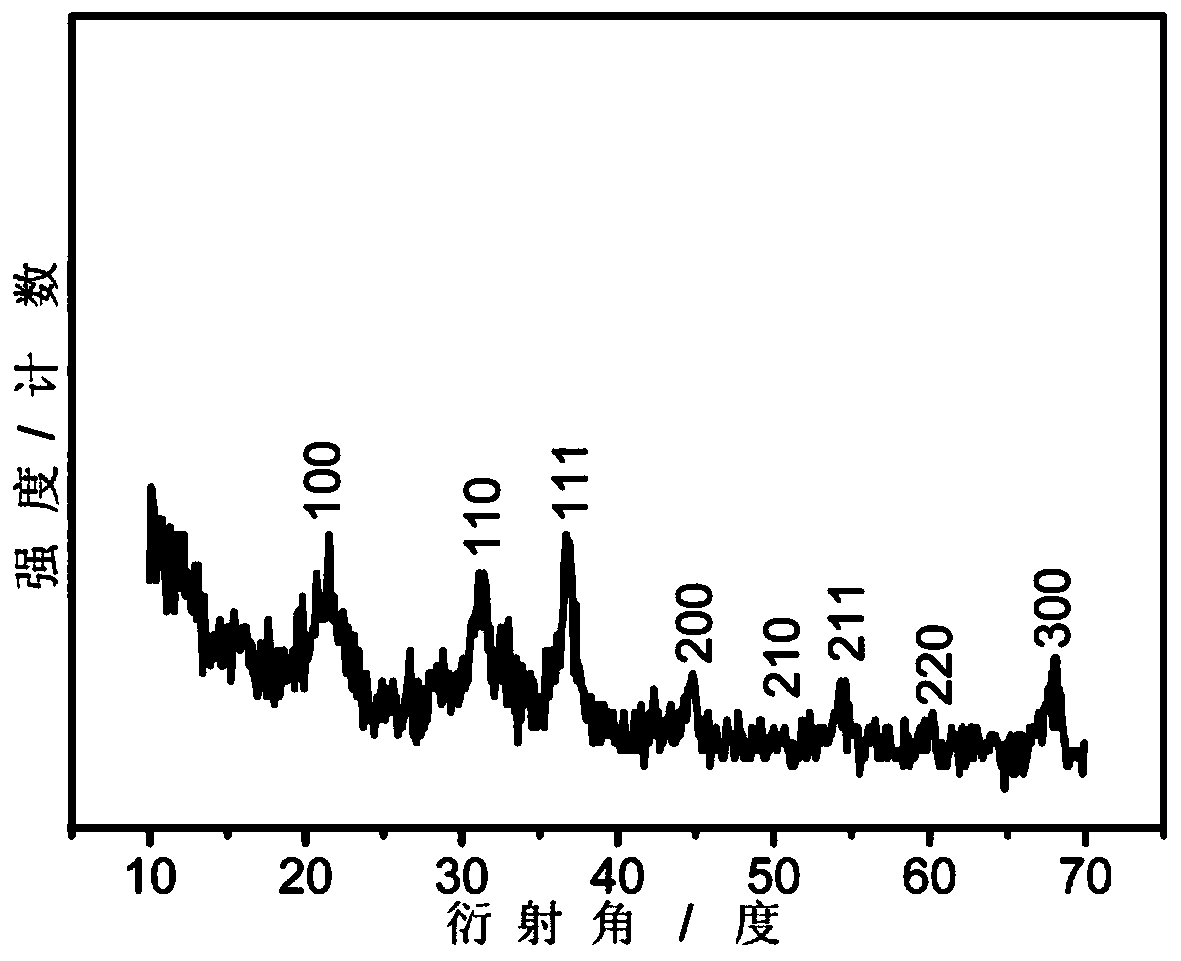

[0040] The phase composition of the samp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com