Nano particle agglomeration type nano porous electrochemical driver and preparation method and testing method thereof

A nano-particle and nano-porous technology, applied in the direction of generators/motors, instruments, measuring electronics, etc., can solve the problem that the response rate and deformation ability cannot be improved at the same time, and achieve simultaneous improvement of response rate and deformation ability, product stability and The effect of high durability and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

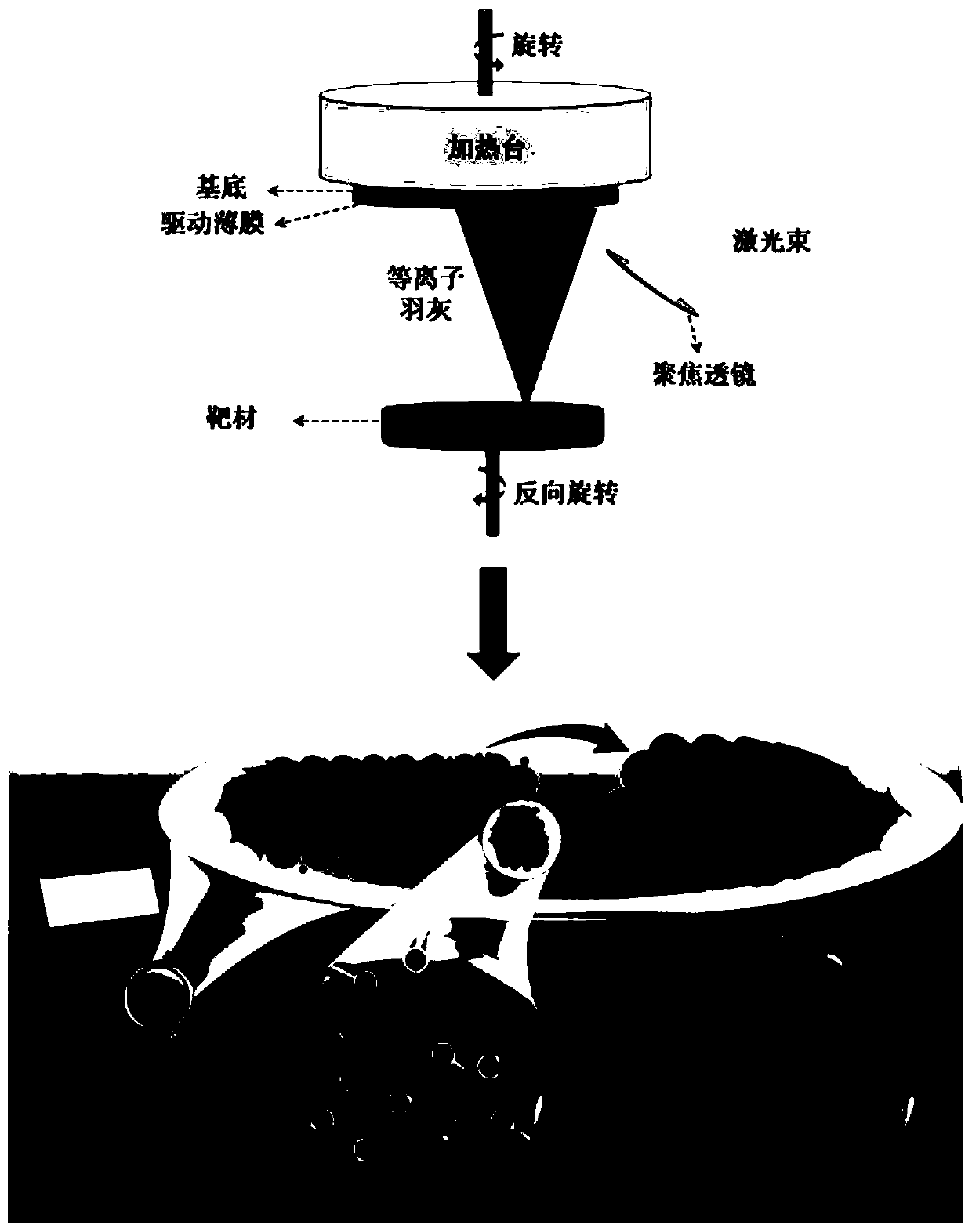

Embodiment 1

[0023] The aluminum foil with a thickness of 100 μm was cold-rolled 5 times with a calender, and finally pressed to a thickness of 4.5 μm; then it was ultrasonically cleaned and vacuum-dried for 24 hours; then it was cut into 12.5×3mm 2 The slender strips are used as substrates for deposition, such as figure 1 As shown, the deposition substrate is fixed upside down on the heating platform, and the molybdenum disulfide target is selected as the target target, and the target target is fixed under the heating platform, and the distance between the target and base is 50 mm; in order to make the film formation more uniform, the heating platform is 2rpm drives the deposition substrate to rotate; in order to ensure the service life of the target, the target rotates in reverse at a speed of 30rpm. Then adjust and stabilize the garnet laser energy to 70mJ / mm 2 ; The laser frequency is set to 1Hz, and it is scanned and bombarded along the radial direction of the target at a speed of 5m...

Embodiment 2

[0026] The tungsten foil with a thickness of 100 μm was cold-rolled 4 times with a calender, and finally pressed to a thickness of 6 μm; then it was ultrasonically cleaned and vacuum-dried for 24 hours; then it was cut into 12.5×3mm 2 The slender strips are used as substrates for deposition, such as figure 1 As shown, the deposition substrate is fixed upside down on the heating platform, and the molybdenum disulfide target is selected as the target target, and the target target is fixed under the heating platform, and the distance between the target and base is 50 mm; in order to make the film formation more uniform, the heating platform is 2rpm drives the deposition substrate to rotate; in order to ensure the service life of the target, the target rotates in reverse at a speed of 30rpm. Then adjust and stabilize the garnet laser energy to 70mJ / mm 2 ; The laser frequency is set to 5Hz, and it is scanned and bombarded at a speed of 5mm / s along the radial direction of the targe...

Embodiment 3

[0029] The aluminum foil with a thickness of 100 μm was cold-rolled 4 times with a calender, and finally pressed to 6 μm; then it was ultrasonically cleaned and vacuum-dried for 24 hours; then it was cut into 12.5×3mm 2 The slender strips are used as substrates for deposition, such as figure 1 As shown, the deposition substrate is fixed upside down on the heating platform, and the molybdenum disulfide target is selected as the target target, and the target target is fixed under the heating platform, and the distance between the target and base is 50 mm; in order to make the film formation more uniform, the heating platform is 2rpm drives the deposition substrate to rotate; in order to ensure the service life of the target, the target rotates in reverse at a speed of 30rpm. Then adjust and stabilize the garnet laser energy to 70mJ / mm 2 ; The laser frequency is set to 10Hz, and it is scanned and bombarded along the radial direction of the target at a speed of 5mm / s; the air pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com