Inlet type cementing filling blocking wall and construction method thereof

A technology for cementing filling and sealing walls, which is used in filling materials, earthwork drilling, safety devices, etc., can solve the problems of material waste, insufficient strength and stability of retaining walls, etc., achieve structural stability, reduce the collapse of retaining walls, increase Effects of strength and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

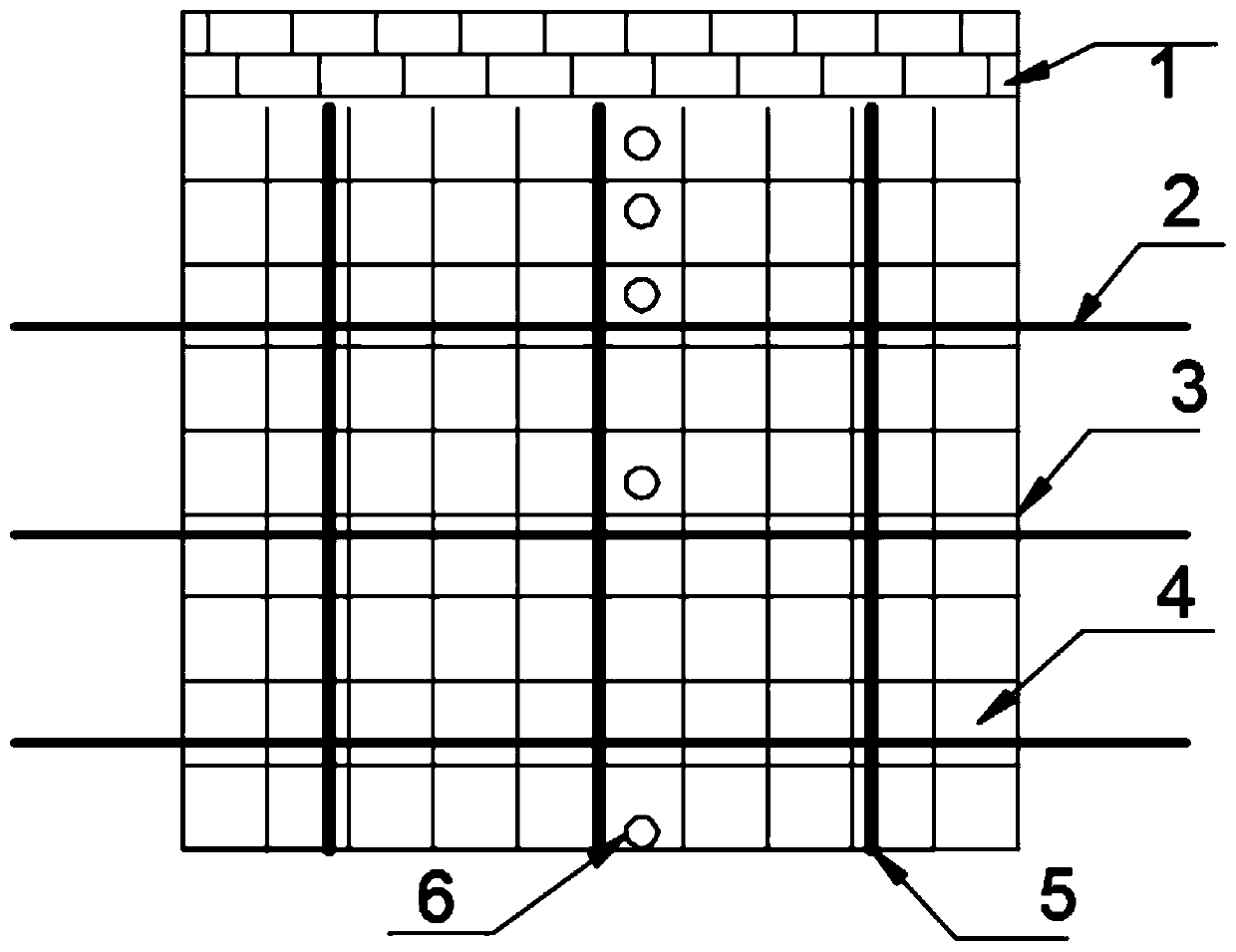

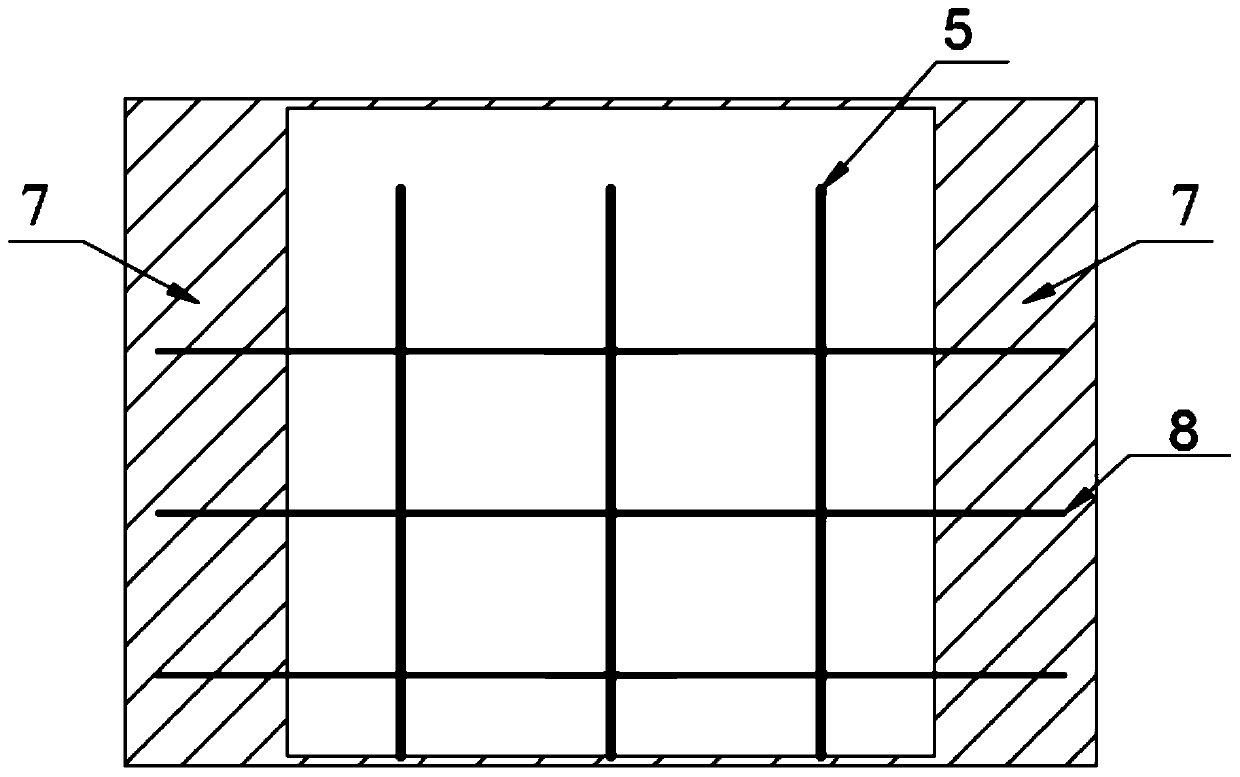

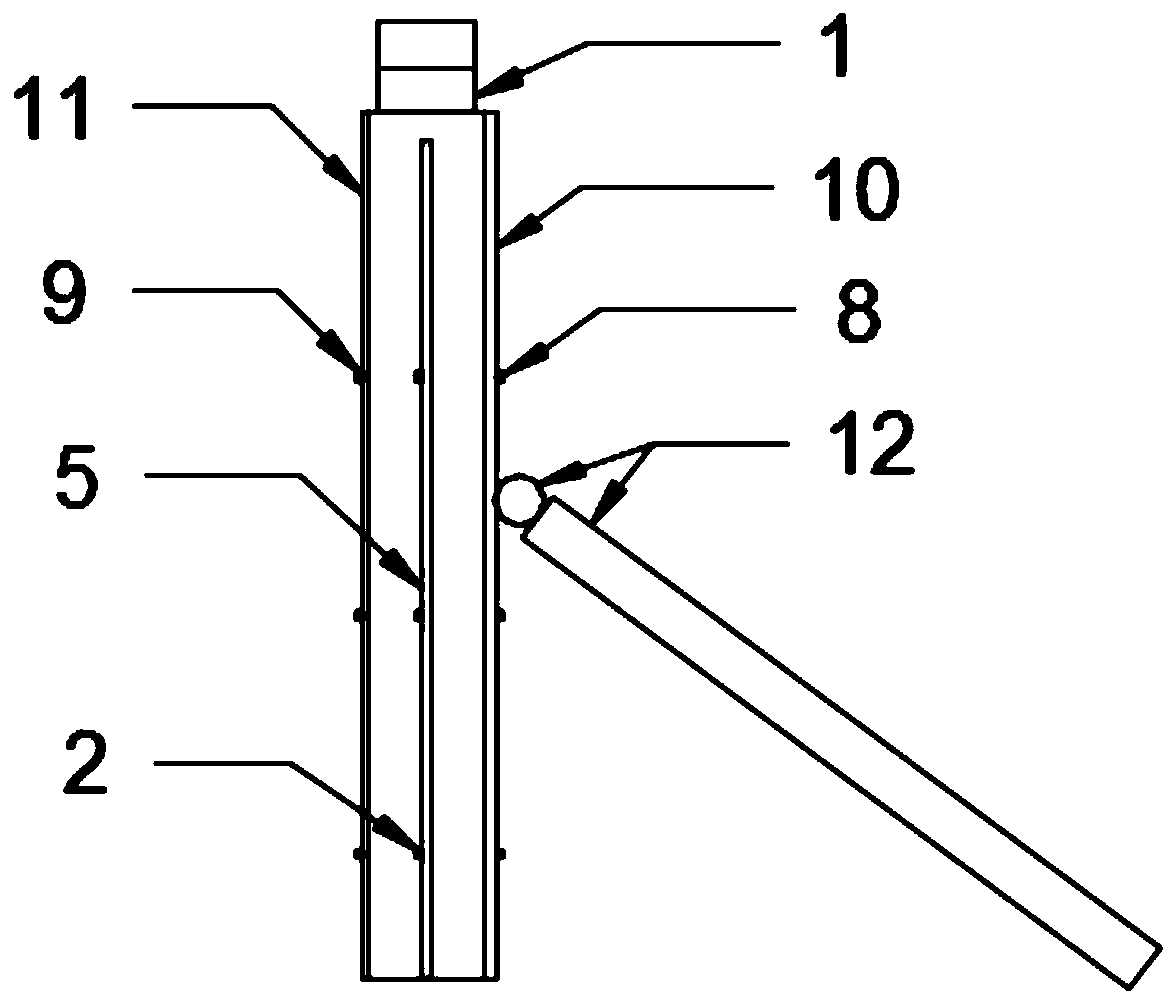

[0049]This embodiment provides an access-type cemented and filled sealing wall, which includes a sealing wall body and a reinforcing component, which is arranged inside the sealing wall body, including reinforcing ribs arranged in a staggered manner and the reinforcing ribs Compatible stiffeners. The reinforcing rib and the reinforcing plate play a basic role of reinforcement inside the sealing wall. In this embodiment, the reinforcing rib includes a reinforcing anchor rod 2 and a vertical rib 5, wherein the reinforcing anchor rod 2 runs through the sealing wall body and its The two ends extend to the outside of the wall body; the vertical bars 5 are arranged inside the block wall body and intersect with the anchor rods. Reinforcing the anchor rod 2 and the vertical rib 5 improves the bending resistance of the sealing wall; the reinforcement part inside the sealing wall is very stable. Specifically, the reinforcing anchor rod 2 and the vertical bar 5 can be selected from No. ...

Embodiment 2

[0054] This example provides Figure 1-3 The construction method of the road-type cemented-fill sealing wall shown includes,

[0055] Pretreatment, clean up the ground of the stope to the solid bottom;

[0056] For reinforcement, use a drilling rig to set reinforcement anchor holes on both sides of the surrounding rock 7. The depth of the reinforcement anchor holes is 800mm, and the height of the stope ground is 500mm. The first hole is constructed. The distance from the third hole is 1m, and the quantity is 3 on both sides (total 6). It is required that the anchor holes on both sides can be connected into a line at a horizontal height; Use a drilling rig to construct formwork anchor holes at 275mm on both sides of the front and back of the rod eye. The hole depth of the formwork anchor holes is 500mm, and the height from the bottom plate is 500mm. Construction of the first hole, the first hole and the second hole, the second and the second hole The height of the three holes...

Embodiment 3

[0062] This embodiment provides a method for constructing an approach-type cemented filling sealing wall for a stope with fractures, including:

[0063] Pretreatment, cleaning the ground of the stope, clearing to the solid bottom, pre-spraying to prevent the slurry from running out during filling, and laying steel mesh at the position corresponding to the bottom of the vertical formwork wall, with a mesh degree of 400×400.

[0064] For reinforcement, use a drilling rig to set reinforcement anchor holes on both sides of the surrounding rock 7. The depth of the reinforcement anchor holes is 800mm, and the height of the stope ground is 500mm. The first hole is constructed. The distance from the third hole is 1m, and the quantity is 3 on both sides (total 6). It is required that the anchor holes on both sides can be connected into a line at a horizontal height; Use a drilling rig to construct formwork anchor holes at 275mm on both sides of the front and back of the rod eye. The ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com