Multi-head branch-control 3D printer

A 3D printer, multi-head technology, used in 3D object support structures, additive manufacturing, coating devices, etc., can solve problems that have not been met, and achieve the effect of improving printing efficiency, strength and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

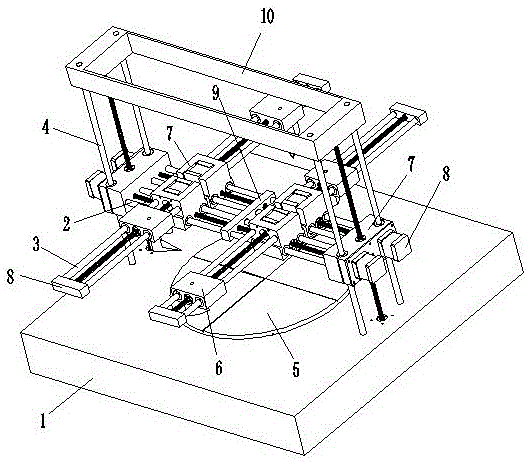

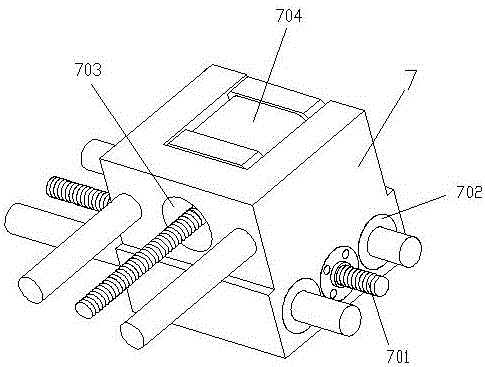

[0018] As shown in the figure, a multi-head controlled 3D printer includes a printing base 1, a horizontal guide rail 2 arranged on the printing base 1, a longitudinal guide rail 3 and a vertical guide rail 4, wherein the two ends of the horizontal guide rail 2 pass through the sliding The block screw mechanism slides back and forth on the vertical guide rail 4, and the longitudinal guide rail 3 slides back and forth on the horizontal guide rail 2 through the slider screw mechanism; the printing base 1 is provided with a printing platform 5 driven by a power mechanism to rotate, The longitudinal guide rails 3 are two guide rails distributed symmetrically along the middle position of the transverse guide rails 2, and two print head mounting sliders 6 are symmetrically arranged on each longitudinal guide rail 3 along its middle position, and each print head mounts the slider 6 The lower part is mounted with 3D printing heads, and the four 3D printing heads on the two longitudinal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com