Deep foundation pit underground drainage pre-buried well grouting plugging construction method

A construction method and pre-buried well technology, which is applied in infrastructure engineering, construction, etc., can solve problems such as poor stability, many uncertain factors, and hidden construction hazards, and achieve uniform distribution, convenient operation, and safe and reliable engineering quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

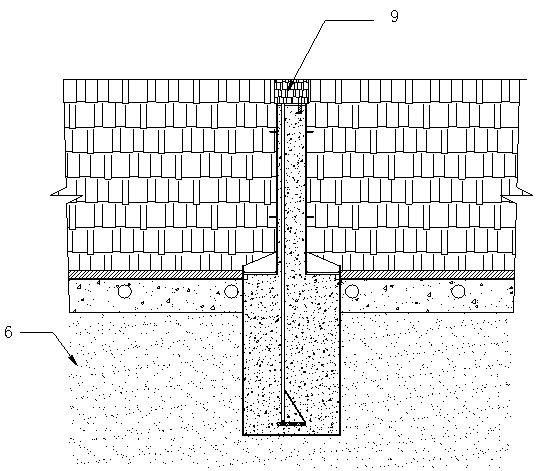

[0028] The construction method of grouting plugging of the deep foundation pit buried drainage pre-buried well of the present invention comprises the following steps:

[0029] a. According to the inner diameter of the pre-buried well, make a plugging round steel plate, weld a drainage pipe, and make a grouting pipe.

[0030] b. Wrap isolation filler 4 around the outer edge of the pre-embedded well head, and the isolation filler is foamed plastic and wrapped with waste packaging bags.

[0031] c. Add gravel in the pre-buried well, install the grouting pipe, and fill the gravel to the predetermined position, which is the drainage flower filter pipe.

[0032] d. Install the plugging round steel plate, and weld the plugging round steel plate with the grouting pipe and the pre-embedded pipe.

[0033] e. The height of the grouting pipe and the drainage pipe shall be connected to the equilibrium position of the groundwater level.

[0034] f. For grouting and secondary grouting, fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com