Pretreatment inkjet ink for digital printing and application method thereof

An inkjet ink and digital printing technology, applied in the field of pretreatment of white inkjet ink and pretreatment inkjet ink, can solve the problems of strong ink absorption and dim color of printed patterns, so as to reduce penetration, solve the problem of dim color and pattern. colorful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

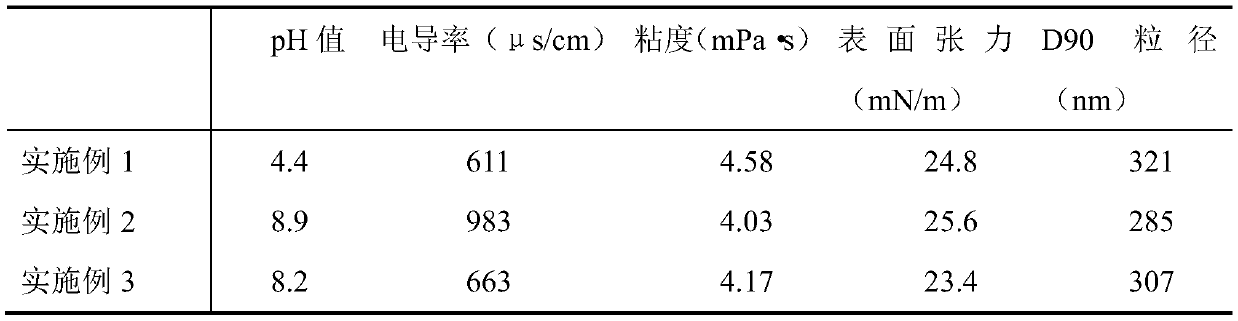

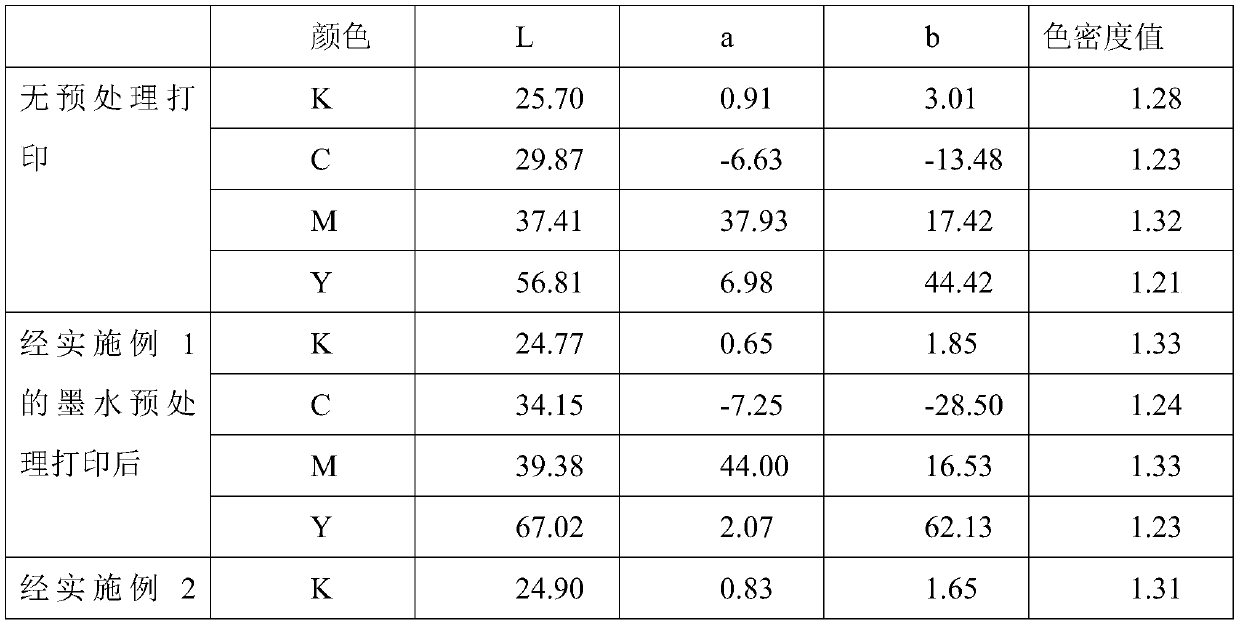

Embodiment 1

[0020] A pre-treatment inkjet ink for digital printing, which is made of the following components by weight percentage: white color paste: 40%, calcium chloride: 3%, ethylene glycol: 10%, TEGO WET260: 1%, benzisothiazolinone: 0.1%, deionized water: the balance; the preparation steps of the pretreatment inkjet ink include: adding deionized water, calcium chloride to the white color paste in sequence , ethylene glycol, TEGO WET260, and benzisothiazolinone, stir and mix each component evenly and then filter through a 0.65 micron filter membrane to obtain the pretreatment inkjet ink; it should be noted that the During the addition process, after each component is added, it should be stirred and mixed with other components before adding the next component.

[0021] In addition, in this embodiment, the white color paste is prepared by the following components by weight percentage: titanium dioxide (average particle size: 350nm): 30%, alkyl quaternary ammonium salt: 4.5%, Surfynol DF...

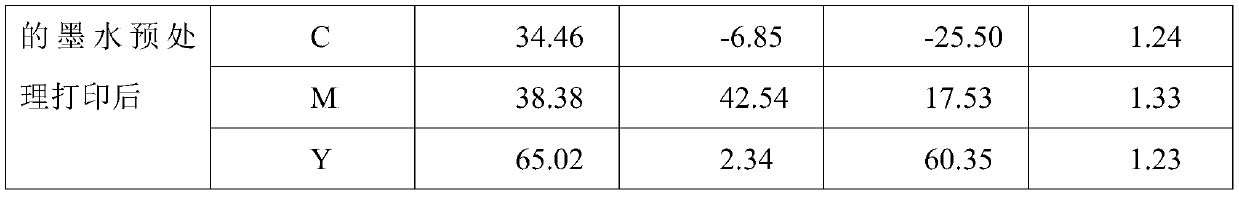

Embodiment 2

[0023] A pretreatment inkjet ink for digital printing, made of the following components by weight percentage: white color paste: 35%, acrylic emulsion: 12%, polyethylene glycol 400: 5%, Surfynol 465 : 1%, benzisothiazolinone: 0.1%, deionized water: the balance.

[0024] Wherein, in this embodiment, the white color paste is made of the following components by weight percentage: nano zinc oxide (average particle diameter 750nm): 40%, carboxylate: 6%, Surfynol DF-110D: 0.2% 1. Sodium hydroxide: 0.5%, deionized water: the rest; the preparation process of the pretreatment inkjet ink and white color paste is similar to that of Example 1, and will not be repeated here.

Embodiment 3

[0026] A pretreatment inkjet ink for digital printing, made of the following components by weight percentage: white color paste: 35%, acrylic emulsion: 12%, glycerol: 5%, Surfynol 485: 1 %, benzisothiazolinone: 0.1%, deionized: the balance.

[0027] Wherein, in this embodiment, the white color paste is made of the following components by weight percentage: nano-alumina (average particle diameter 500nm): 40%, acrylic acid-styrene copolymer: 5%, Surfynol DF-110D : 0.2%, monoethanolamine: 1%, deionized water: the balance; the preparation process of the pretreatment ink-jet ink and white color paste is similar to that of Example 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com