Automobile sound insulation pad skin and preparation thereof

A technology of automobile sound insulation pad and skin, which is applied in the field of automobile sound insulation pad skin and its preparation, which can solve the problems of the mechanical performance and temperature resistance performance of the sound insulation pad skin, and lose the function of use, so as to achieve the effect of ensuring the mechanical performance and temperature resistance performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

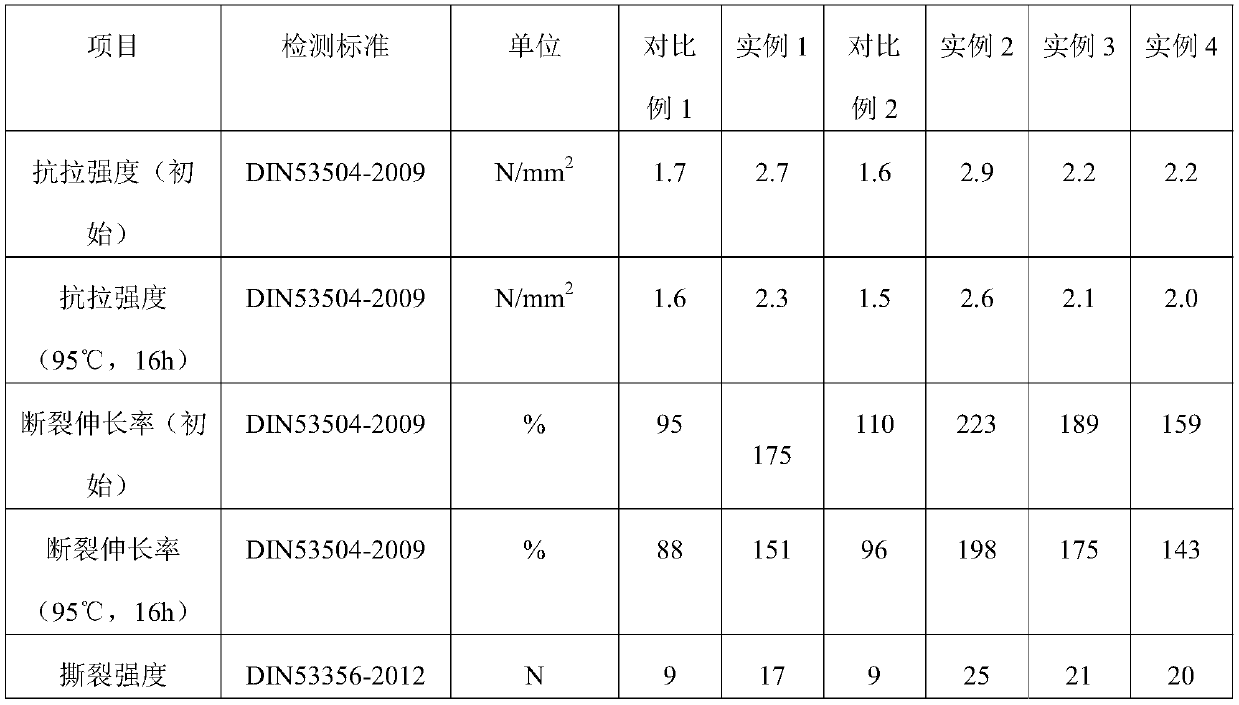

[0024] A kind of preparation method of automobile sound insulation pad epidermis is provided in each following embodiment, specifically comprises the following steps:

[0025] Step 1: Weigh all raw materials according to Table 1 below, and mix them evenly in a mixer;

[0026] Step 2: Put the uniformly mixed material into the pressurized internal mixer for mixing and plasticization. The internal mixing temperature is 160-180°C and the time is 30-50min. After completion, the plasticized material is passed through the conical twin-screw feeder Forcibly fed into the model KSJ-150 extruder produced by Kunshan Kexin Rubber and Plastic Machinery Co., Ltd., and passed through a T-shaped die head in the shape of a coat hanger, three-roll calendering, traction, and shearing to obtain a plate or sheet and Extrusion, the temperature of the extruder can be set as follows: Zone 1: 160±20℃, Zone 2: 175±20℃, Zone 3: 175±20℃, Zone 4: 170±20℃, Zone 5: 165±20 ℃, zone 6: 165±20℃, zone 7: 165±20℃...

Embodiment 5- Embodiment 12

[0038] Compared with Example 1, most of them are the same, except that in this example, EPDM is replaced by SEBS, SIS, SEPS, SBS, EVA, EMA, TPU or TPV respectively.

[0039] The above-mentioned SEBS, SIS, SEPS, SBS, and ethylene-propylene rubber can also be replaced by their oil-extended products. The specific preparation method is as follows: take SEBS and other styrene block copolymer-like elastomers or ethylene-propylene rubber, and heat up in a high-speed mixer. To 40-60°C, add rubber extension oil (paraffin oil) at a mass ratio of 1:1, and treat for 10-20 minutes to obtain an oil-extended product.

Embodiment 13- Embodiment 14

[0041] Compared with Example 1, most of them are the same, except that in this example, PE is replaced by PP or PS of equal quality.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com