Synthesis method of cyclopropyl methyl ketone

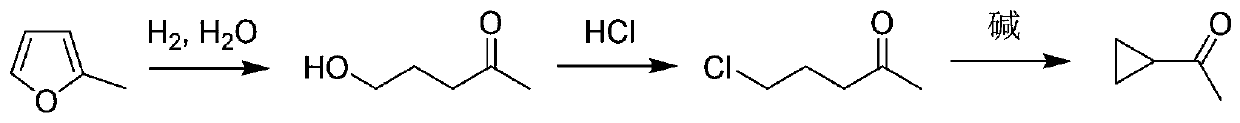

A technology of cyclopropyl methyl ketone and synthesis method, which is applied in the preparation of heterocyclic compounds, the preparation of carbon-based compounds, chemical instruments and methods, etc., can solve the problems of complex process, industrial scale, and high production difficulty, and achieve atomic economy. High performance, low cost of raw materials, mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Synthesis of cyclopropylmethyl ketone: In a 1000ml hydrogenation kettle, add 400g of 2-methylfuran and 100g of water, 2g of 5% palladium carbon catalyst, replace with nitrogen, then replace with hydrogen, stir to control the reaction temperature for 28 ℃, use a hydrogen balloon to continue the hydrogenation reaction, the reaction ends after 3 hours, the reaction solution is filtered after nitrogen replacement, the catalyst can be applied to the next batch, the reaction solution is allowed to stand for stratification, and the water layer can be applied to the next batch; the organic phase is acetyl-n-propane Alcohol 448g, purity 95.3%.

[0033] In a 1000ml three-neck flask, add 340g of 20% hydrochloric acid, heat to 90°C, add dropwise 100g of the above-mentioned acetyl n-propanol, and distill to collect the azeotrope 5-chloro-2-pentanone and dilute acid water. After the dropwise addition, continue to distill until no organic phase is evaporated. After standing and strati...

Embodiment 2

[0036] Synthesis of cyclopropylmethyl ketone: In a 1000ml hydrogenation kettle, add 400g of 2-methylfuran and 100g of water, 2g of 10% palladium carbon catalyst, replace with nitrogen, then replace with hydrogen, stir to control the reaction temperature 30 ℃, continue the hydrogenation reaction with a hydrogen balloon, the reaction ends after 2.5 hours, the reaction solution is filtered after nitrogen replacement, the catalyst can be applied to the next batch, the reaction solution is allowed to stand for stratification, and the water layer can be applied to the next batch; Alcohol 448g, purity 95.5%.

[0037] In a 1000ml three-neck flask, add 340g of 15% hydrochloric acid, heat to 92°C, add dropwise 100g of the above-mentioned acetyl n-propanol, and distill to collect the azeotrope 5-chloro-2-pentanone and dilute acid water. After the dropwise addition, continue to distill until no organic phase evaporates. After standing and layering, the organic phase obtains 130 g of 5-chl...

Embodiment 3

[0040] Synthesis of cyclopropyl methyl ketone: In a 1000ml hydrogenation kettle, add 400g of 2-methylfuran and 100g of water, 2g of 10% palladium carbon catalyst, replace with nitrogen, then replace with hydrogen, stir to control the reaction temperature 25 ℃, continue the hydrogenation reaction with a hydrogen balloon, the reaction ends after 2 hours, the reaction solution is filtered after nitrogen replacement, the catalyst can be applied to the next batch, the reaction solution is allowed to stand for stratification, and the water layer can be applied to the next batch; Alcohol 448g, purity 95.2%.

[0041] In a 1000ml three-neck flask, add 340g of 20% hydrochloric acid, heat to 95°C, add dropwise 100g of the above-mentioned acetyl n-propanol, and distill to collect the azeotrope 5-chloro-2-pentanone and dilute acid water. After the dropwise addition, continue to distill until no organic phase evaporates. After standing and stratifying, the organic phase is 130 g of 5-chloro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com