A kind of preparation method of recombinant wood

A technology of reconstituted wood and pre-curing, applied in the direction of wood heating, wood impregnation, and manufacturing tools, etc., can solve the problems of insufficient strength, difficult to achieve, insufficient toughness, etc., and achieve the effect of improving curing uniformity, improving uniformity, and preventing cracking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

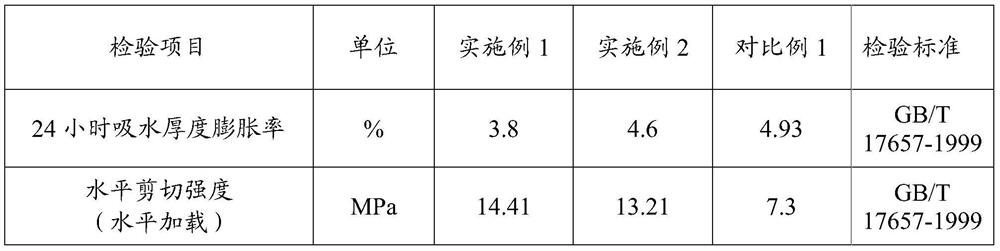

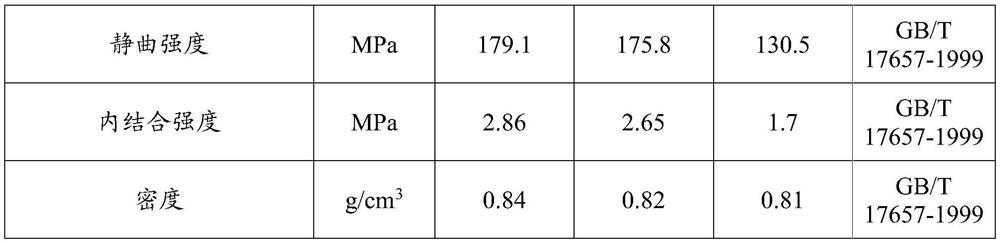

Examples

preparation example Construction

[0026] The invention provides a method for preparing recombined wood, comprising the following steps:

[0027] a) The recombined wood material impregnated with thermosetting resin glue is pressed in a mold to obtain a recombined wood lumber to be cured; then the restructured wood lumber to be cured is heated and cured, demoulded to obtain a pre-cured restructured wood lumber;

[0028] b) along the length direction of the pre-cured recombined timber, install a fixed plywood on its two opposite sides; Metal plate;

[0029] c) Microwave irradiation is carried out along the length direction of the pre-cured recombined wood square on its two side surfaces not equipped with the fixing splints to obtain recombined wood.

[0030] In the preparation method provided by the present invention, firstly, the recombined wood raw material is immersed in the glue solution of thermosetting resin. Wherein, the recombined wood raw material is preferably a wood veneer that has been decomposed an...

Embodiment 1

[0047] 1) Rotary cutting: Use the veneer rotary cutting machine to process poplar logs imported from Russia and then peel and trim the edges to make a rectangular wooden veneer. The size and moisture content parameters of the veneer after rotary cutting are: length The thickness is 1300mm, the width is 550mm, the thickness is 1.3±0.15mm, and the moisture content is 120±20%. The veneers that have been peeled are neatly stacked on the temporary bracket and temporarily stored, and then enter the next step of processing.

[0048] 2) Deflagging: Send the rotary-cut wood veneers to the deflaking machine one by one according to the longitudinal grain direction of the fiber arrangement. The gap between the pressing rollers of the deflaking machine is controlled to be 0.9±0.1mm, and the speed of the pressing rollers is 50r / min. After defrosting, the treated veneer is obtained. The veneer after the disentangling treatment is a network structure veneer that is not broken in the longitud...

Embodiment 2

[0058] 1) Rotary cutting: use a rotary cutting machine to cut Shandong fast-growing poplar into wooden veneers. The thickness of the veneer is 1.7±0.1mm, the width is 600mm, the length is 650mm, and the moisture content is 130±10%.

[0059] 2) Deflagging: According to the deflaking method in Example 1, the only difference is that the gap between the rollers of the deflaker is 1.0±0.1mm, and the rotational speed of the rollers is 40r / min.

[0060] 3) Drying before gluing: Put the treated veneers obtained by defrosting into a mesh belt dryer for drying treatment at a temperature of 80-120°C to make the moisture content to 10±3%;

[0061] 4) Impregnation glue: use the phenolic resin impregnation glue in Example 1, dilute the glue solution to a solid content of 20-25wt%, adopt the method of normal pressure dipping, the dipping time is 20min, and the dipping amount is controlled at the veneer 20 ± 2 wt% of the mass. After the dipping is completed, take out the wood veneer, drain t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com