Removal device for adhering sand in mold cavity of pig iron casting

A technology for pig iron castings and removal devices, which is applied in the directions of cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of long removal time and low removal rate, so as to reduce the removal effect, reduce the removal efficiency, and reduce the adhesion force. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some of the embodiments of the present invention, not all of them.

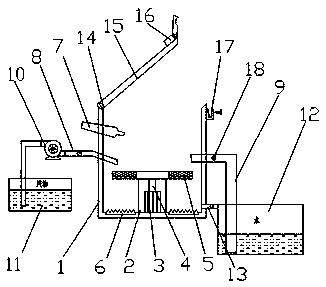

[0020] refer to figure 1 A device for removing sticky sand inside a cast iron casting cavity, comprising an ignition box 1, a motor room 2 is arranged at the center of the bottom wall of the ignition box 1, a motor 3 and a drive shaft 4 are arranged in the motor room 2, and the drive shaft 4 The top end is fixed at the center of the rotating sieve plate 5, the gap between the rotating sieve plate 5 and the side wall of the motor room 2 is 4-5 mm, the center of the rotating sieve plate 5 is solid and the rest of the sieve plate The area of the solid position of 5 is greater than the bottom area of the motor room 2; the bottom wall of the ignition box...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com