V-shaped filter tank with produced water tanks arranged below filter tanks and working method thereof

A filter and pool technology, applied in the direction of separation methods, chemical instruments and methods, fixed filter elements, etc., can solve the problems of V-shaped filter with large floor area, large floor area, complex pool structure, etc. Achieve the effect of reducing the amount of excavated earthwork and foundation treatment area, reducing the occupied area, and reducing project investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

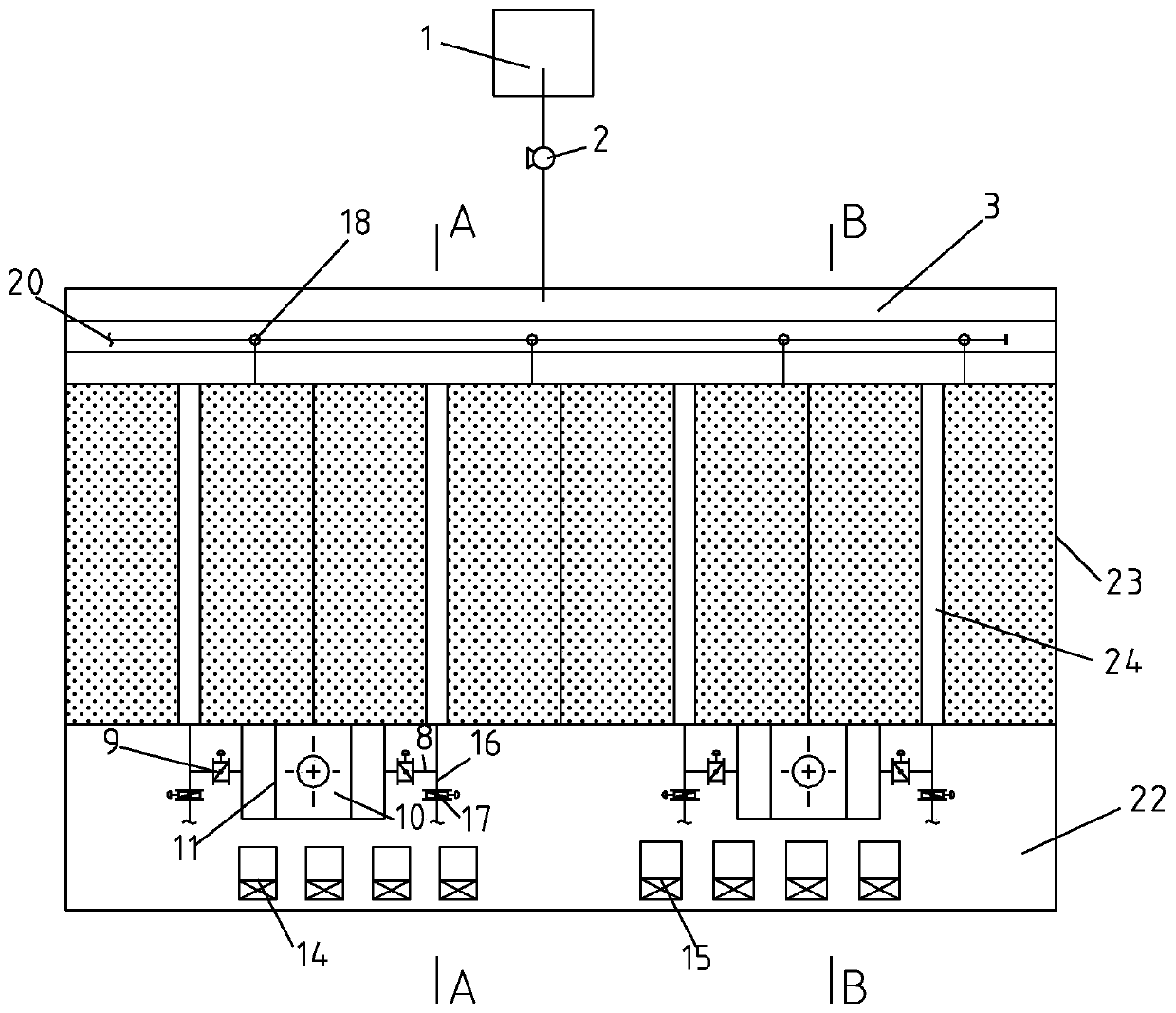

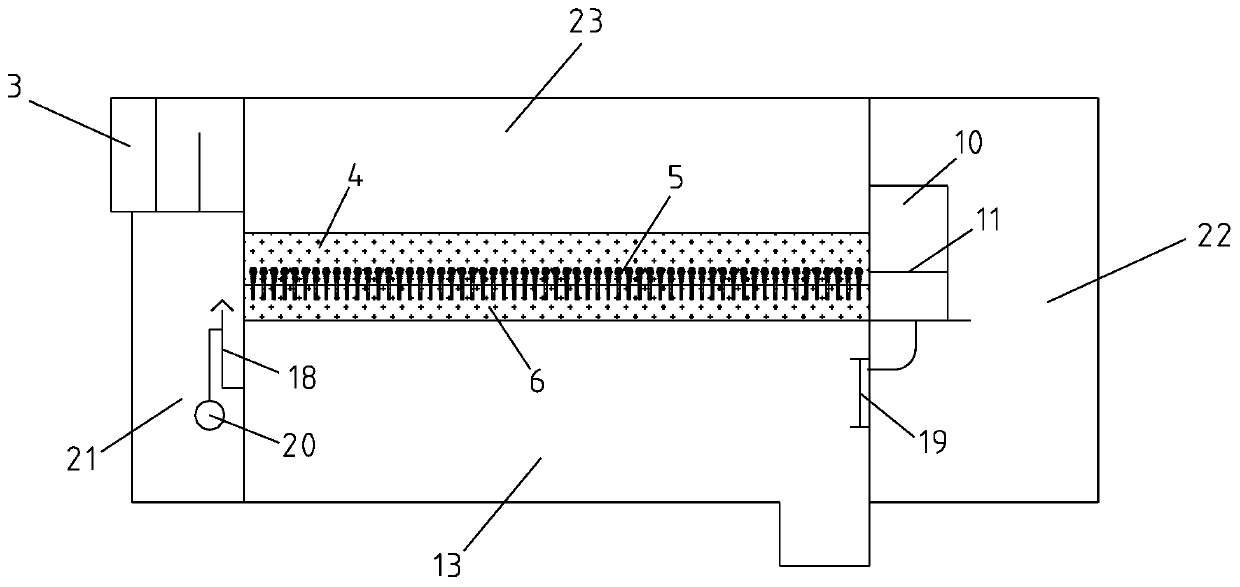

[0027] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0028] Such as Figure 1-Figure 3 As shown, a kind of water production pond of the present invention is located at the V-shaped filter pond below the filter pond, comprises the V-shaped filter pond that is made up of filter pond 23 and water production pond 13; The two ends of described filter pond 23 along the longitudinal direction are respectively The water inlet end and the water outlet end are respectively provided with a filter body on both sides of the center along the transverse direction, a water storage chamber 6 is arranged at the bottom of the filter body, and a filter head 5 is arranged on a filter plate between the water storage chamber 6 and the filter material 4; A drainage tank 24 is arranged between the pool body, and an air-water chamber 7 is arranged at the bottom of the drainage groove 24; the water storage chamber 6 and the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com