Preparation method and application of anti-allergy compound

A compound and extract technology is applied in skin care preparations, medical preparations containing active ingredients, pharmaceutical formulations, etc. The effect of analgesic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

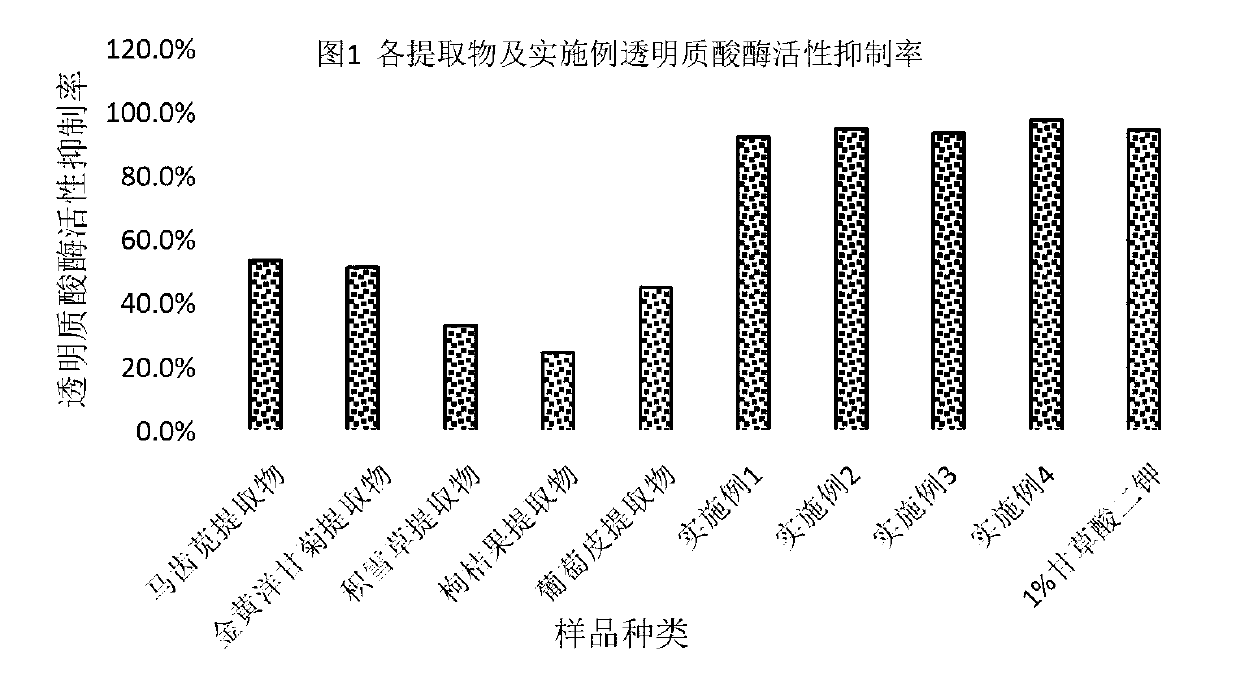

Problems solved by technology

Method used

Image

Examples

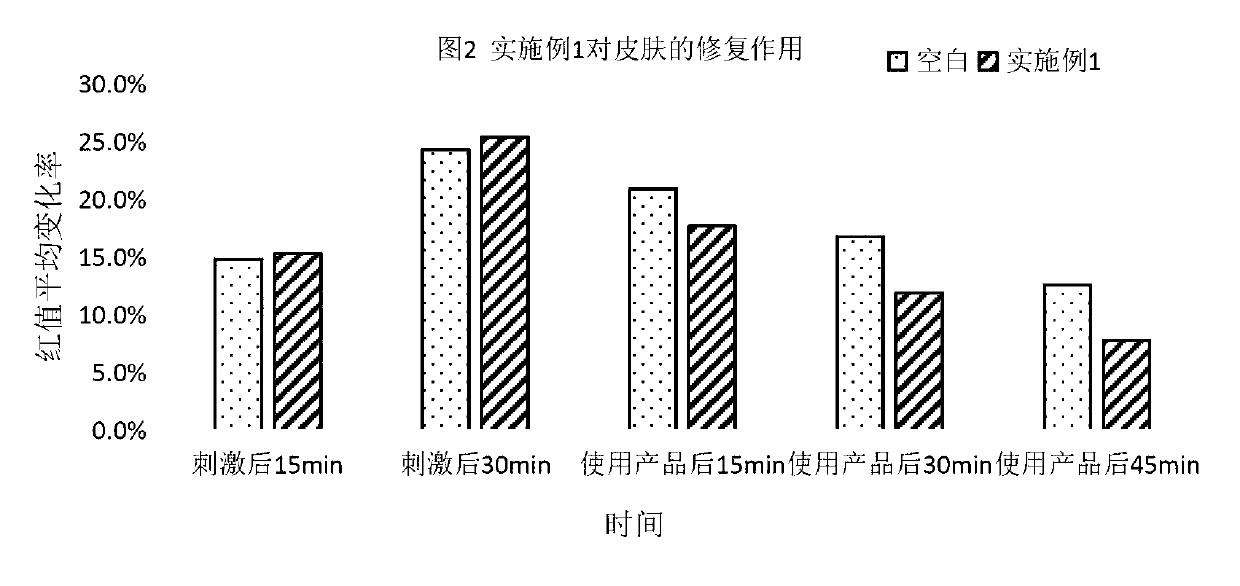

Embodiment 1

[0033] 1. Inoculate Saccharomyces cerevisiae cultured on a shaker in advance into yeast medium (YPD medium) for fermentation. The fermentation conditions are: pH range 3.0-7.0, fermentation temperature 25°C, shaker speed 80rpm, fermentation time 2d.

[0034] 2. Use a TDL-80-2B low-speed centrifuge to centrifuge the fermented broth at a speed of 7000 rpm / min, collect and separate the supernatant, and filter it through a 0.22 μm microporous membrane.

[0035]3. The solvent used for the extraction of purslane is 60% ethanol, the ratio of solid to liquid is 1:15, the ultrasonic-assisted extraction time at room temperature is 30 minutes, and then heated for 2 hours, the extraction temperature is 70°C, the ethanol is concentrated at 65°C, 1um filter paper plate Filtration, macroporous resin for separation and purification, the injection speed, eluent concentration and elution speed are respectively 0.5ml / min, 60% ethanol, 1ml / min. Add butanediol to make a 1:1 solution of liquid to b...

Embodiment 2

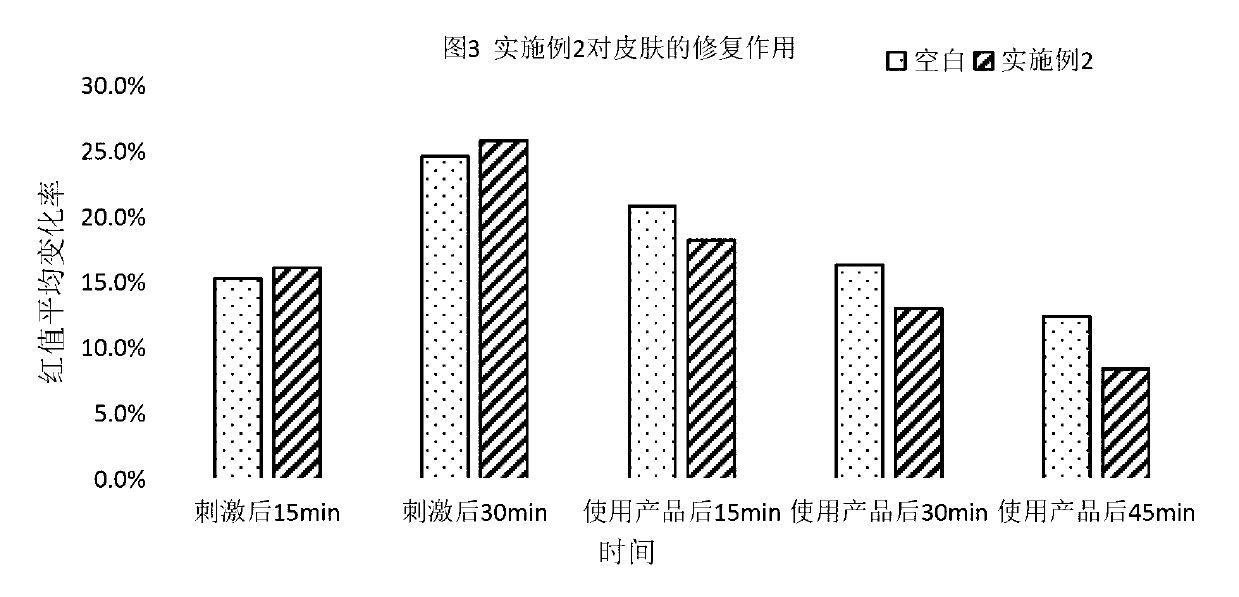

[0042] 1. Inoculate Saccharomyces cerevisiae cultured on a shaker in advance into yeast medium (YPD medium) for fermentation. The fermentation conditions are: pH range 3.0-7.0, fermentation temperature 30°C, shaker speed 150rpm, fermentation time 4d.

[0043] 2. Use a TDL-80-2B low-speed centrifuge to centrifuge the fermented broth at a speed of 7000 rpm / min, collect and separate the supernatant, and filter it through a 0.22 μm microporous membrane.

[0044] 3. The solvent used for the extraction of purslane is 65% ethanol, the ratio of solid to liquid is 1:20, the ultrasonic-assisted extraction time is 40min, and then heated for 2h, the extraction temperature is 75°C, the ethanol is concentrated at 70°C, and filtered with a 1um filter paper board , macroporous resin for separation and purification, the injection speed, eluent concentration and elution speed are respectively 1ml / min, 60% ethanol, 1.8ml / min. Add butanediol to make a solution with a ratio of liquid to butanediol...

Embodiment 3

[0051] 1. Inoculate Saccharomyces cerevisiae cultured on a shaker in advance into yeast medium (YPD medium) for fermentation. The fermentation conditions are: pH range 3.0-7.0, fermentation temperature 32°C, shaker speed 180rpm, fermentation time 3d.

[0052] 2. Use a TDL-80-2B low-speed centrifuge to centrifuge the fermented broth at a speed of 7000 rpm / min, collect and separate the supernatant, and filter it through a 0.22 μm microporous membrane.

[0053] 3. The solvent used for the extraction of purslane is 70% ethanol, the ratio of solid to liquid is 1:25, the ultrasonic-assisted extraction time is 60min, and then heated for 4h, the extraction temperature is 85°C, the ethanol is concentrated at 75°C, and filtered with a 1um filter paper board , macroporous resin for separation and purification, the injection speed, eluent concentration and elution speed were 1.8 ml / min, 70% ethanol, 3.5ml / min. Add butanediol to make a solution with a ratio of liquid to butanediol of 1:1. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com