Carbon nanotube composite structure and preparation method thereof

A carbon nanotube composite and carbon nanotube technology, applied in the direction of carbon nanotubes, oriented carbon nanotubes, nanocarbons, etc., can solve the problem of poor deformation resistance of carbon nanotube sponges, achieve good adsorption and reduce capacity Attenuation, the effect of prolonging the cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

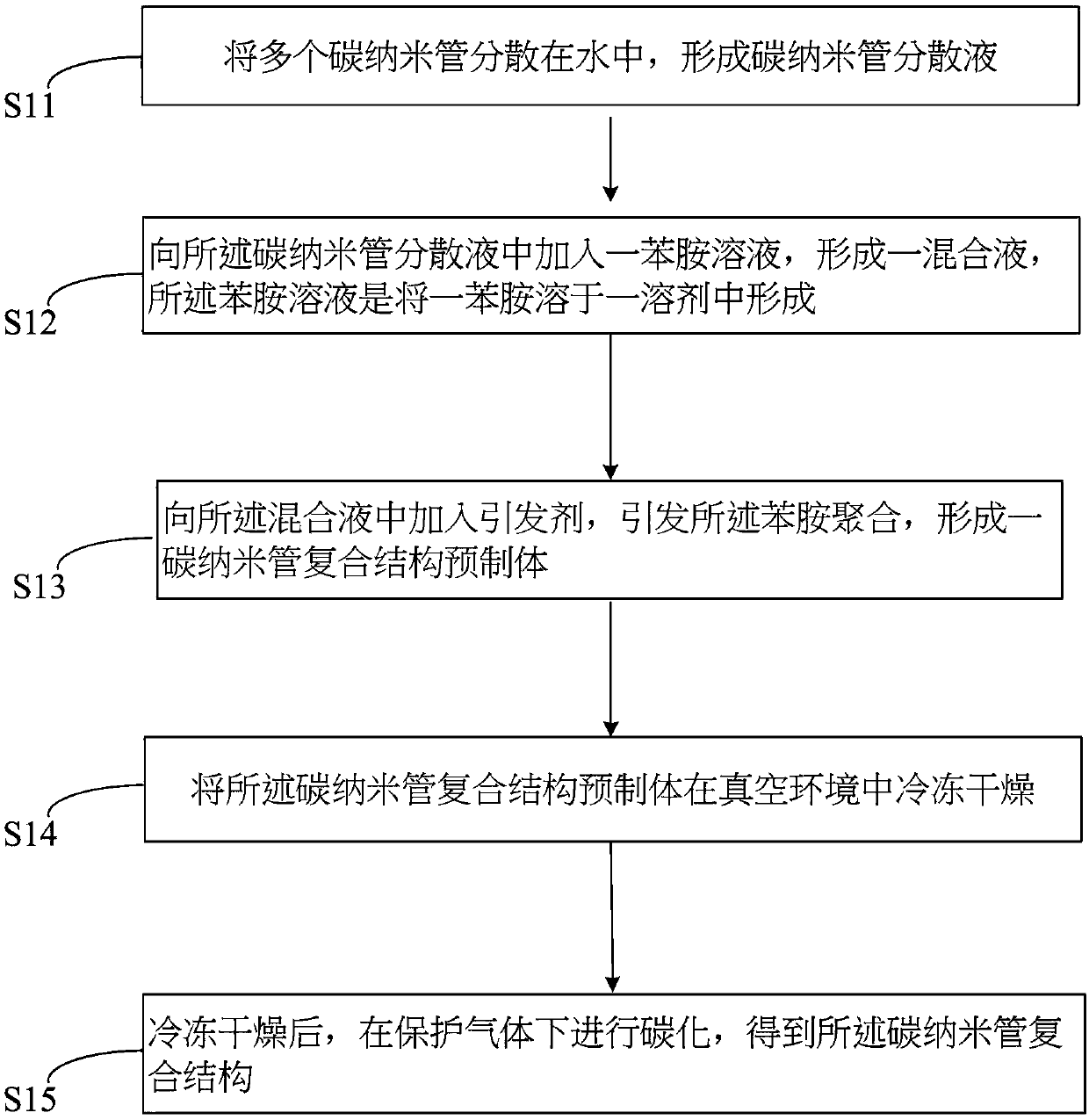

[0041] See figure 1 and Figure 9 , the first embodiment of the present invention provides a method for preparing a carbon nanotube composite structure 10, comprising the following steps:

[0042] S11, dispersing a plurality of carbon nanotubes 12 in water to form a carbon nanotube dispersion;

[0043] S12, adding an aniline solution to the carbon nanotube dispersion to form a mixed solution, the aniline solution is formed by dissolving aniline in a solvent;

[0044] S13, adding an initiator to the mixed solution to initiate the polymerization of the aniline to form a carbon nanotube composite structure preform;

[0045] S14, freeze-drying the carbon nanotube composite structure preform in a vacuum environment; and

[0046] S15, after freeze-drying, carbonization is performed under a protective gas to obtain the carbon nanotube composite structure 10 .

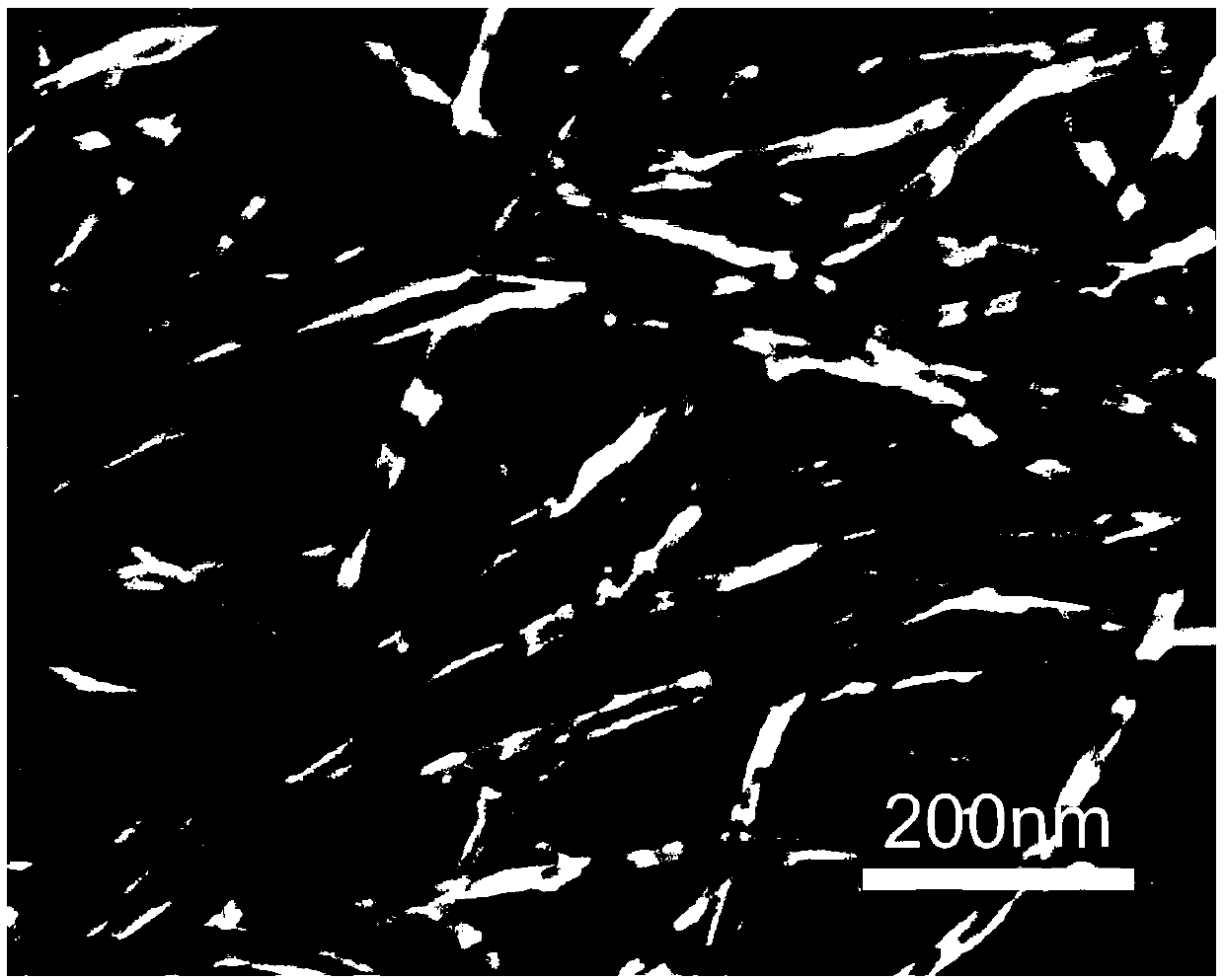

[0047] In step S11 , the plurality of carbon nanotubes 12 include single-wall carbon nanotubes 12 , double-wall carbon n...

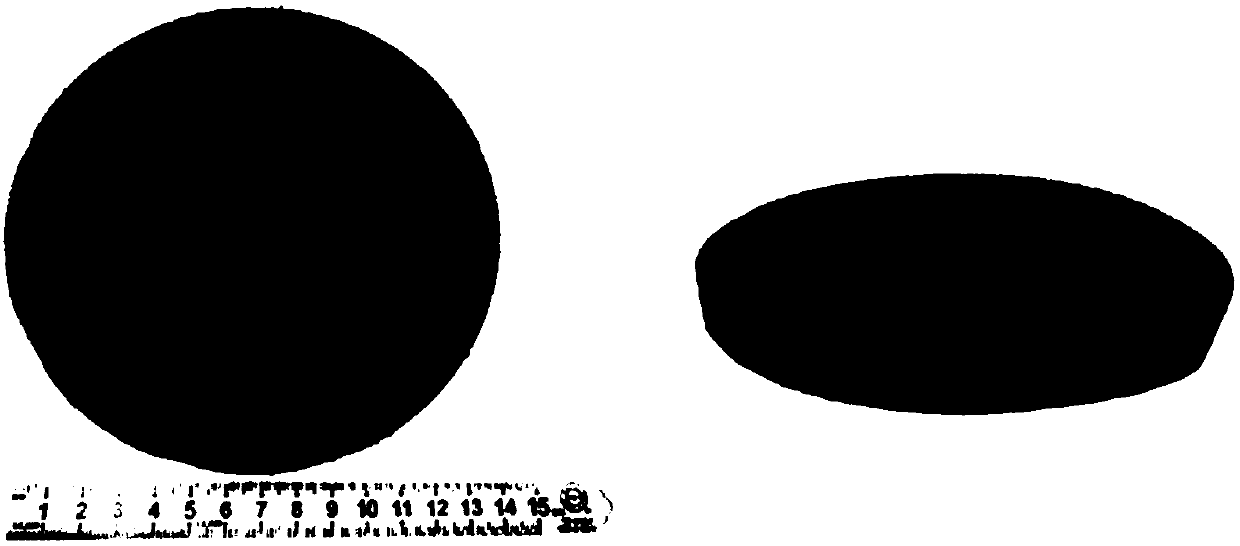

Embodiment

[0056] Using a cell ultrasonic instrument, 100 mg of carbon nanotubes scraped off from the super-parallel carbon nanotube array and 15 mg of polyvinylpyrrolidone (PVP K90) were ultrasonically dispersed in pure water for 30 minutes to form a uniform carbon nanotube dispersion. Then the carbon nanotube dispersion was transferred to a three-neck flask, cooled with an ice bath and stirred magnetically. Dissolve 150 μL of aniline (ANI, J&K Scientific, 98.5%) in 20 ml of ultrapure water to form an aqueous solution of aniline, and then add 5 mL of hydrochloric acid (0.1 mol L -1 ), forming an aniline solution. Then slowly add the prepared aniline solution into the carbon nanotube dispersion, and continue stirring for 30 minutes after the dropwise addition is completed. Then, 50 mL of ammonium persulfate aqueous solution (ammonium persulfate 368 mg) was slowly added dropwise under vigorous stirring and nitrogen flow, and after stirring for 24 hours, a CNT / PANI hydrogel was formed. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com