System and method for particulate filter regeneration

A soot, destination technology, applied in the field of systems and methods for particulate filter regeneration, capable of solving problems such as injector degradation, temperature rise of urea injectors, impact on emission quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

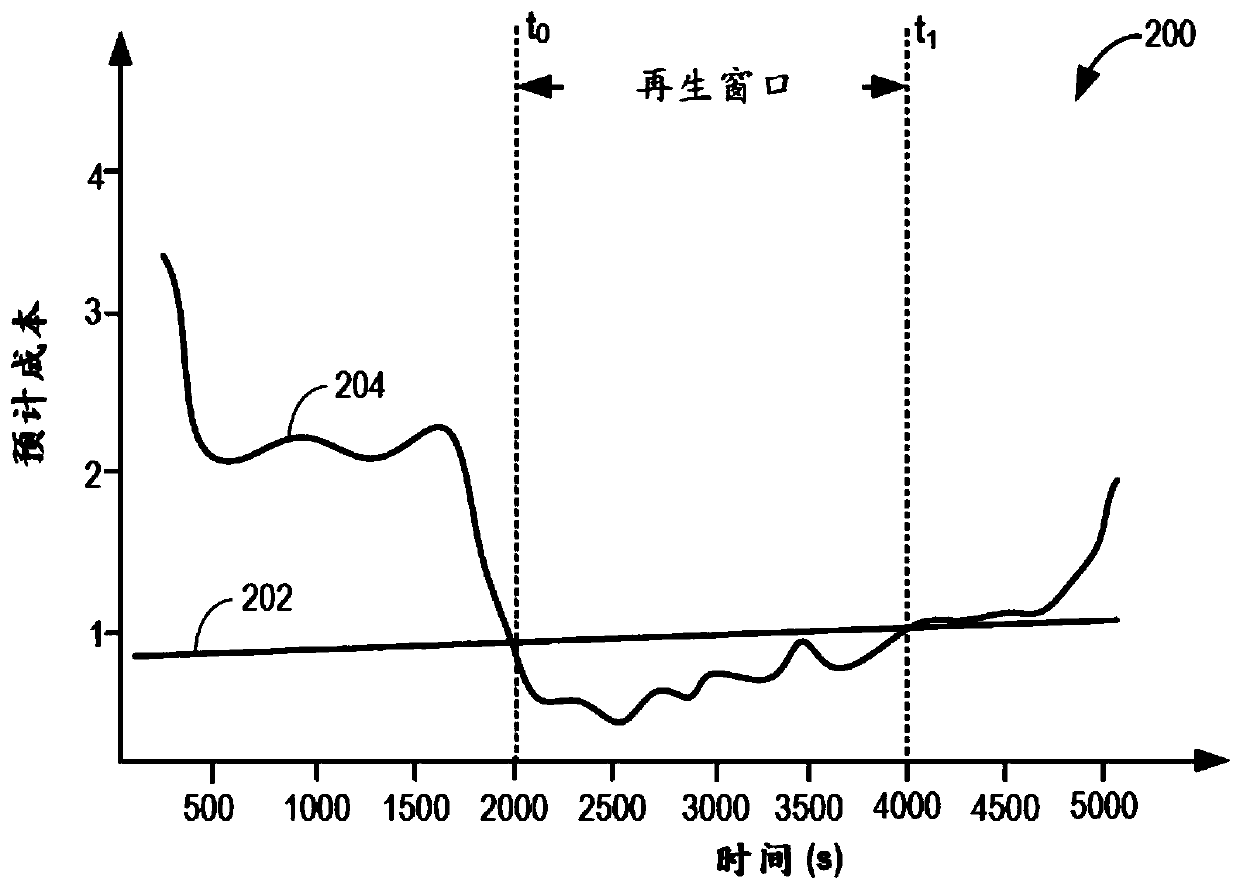

[0015] The following description relates to systems and methods for regenerating a particulate filter (PF) based on predicted vehicle driving conditions and catalyst ammonia storage capacity. PF and Selective Catalytic Reduction (SCR) catalysts can be coupled to figure 1 The exhaust passage of the diesel engine shown. The engine controller can be configured to execute control routines such as figure 2 and image 3 An example routine to opportunistically regenerate the PF and adjust the ammonia storage setpoint and urea injection limit prior to regeneration. figure 2 and image 3 The graph shown in shows the fuel cost associated with performing regeneration and the regeneration variation based on the regeneration start time. Figure 6 An exemplary regeneration of the PF during a drive cycle is shown in .

[0016] now refer to figure 1 , shows a schematic diagram showing one cylinder of a multi-cylinder internal combustion engine 10 that may be included in the propulsion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com