Fuel cell bipolar plate and electric stack

A fuel cell and bipolar plate technology, applied in fuel cells, circuits, electrical components, etc., can solve the problem of leakage of coolant and anode reactants or cathode reactants, cooling liquid inlet and outlet occupying bipolar plate space, and gas inlet and outlet Outlet design restrictions and other issues to achieve the effect of preventing mutual channeling, improving mechanical strength, and achieving water and heat balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

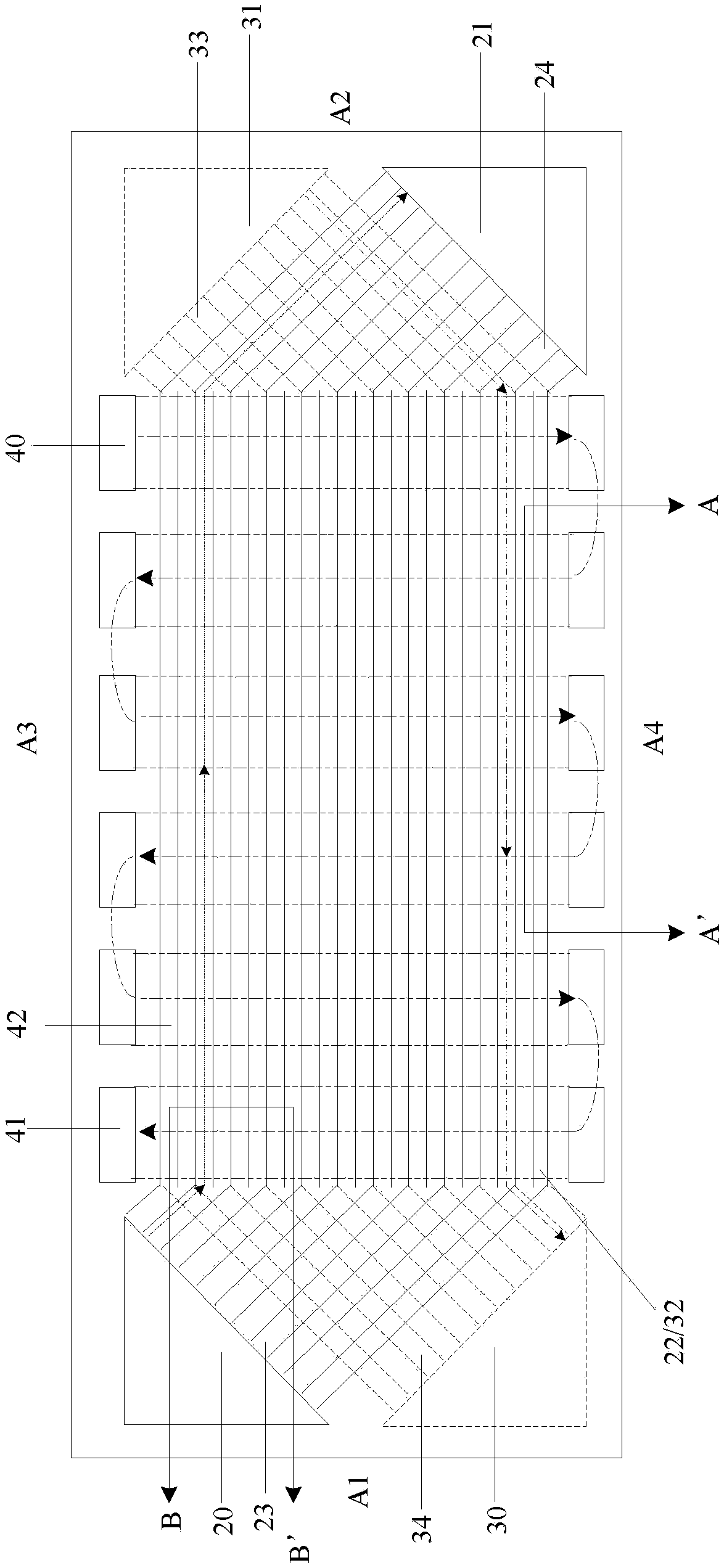

[0041] As mentioned in the background technology, the inlet and outlet of the cooling liquid will occupy the space on the short side of the bipolar plate, which will limit the area of the inlet and outlet of the anode reactant and the inlet and outlet of the cathode reactant, and will also reduce the mechanical strength of the bipolar plate. The inlet and outlet of the cooling liquid are adjacent to the inlet and outlet of the anode reactant or the inlet and outlet of the cathode reactant, which may easily cause leakage between the coolant and the anode reactant or the cathode reactant.

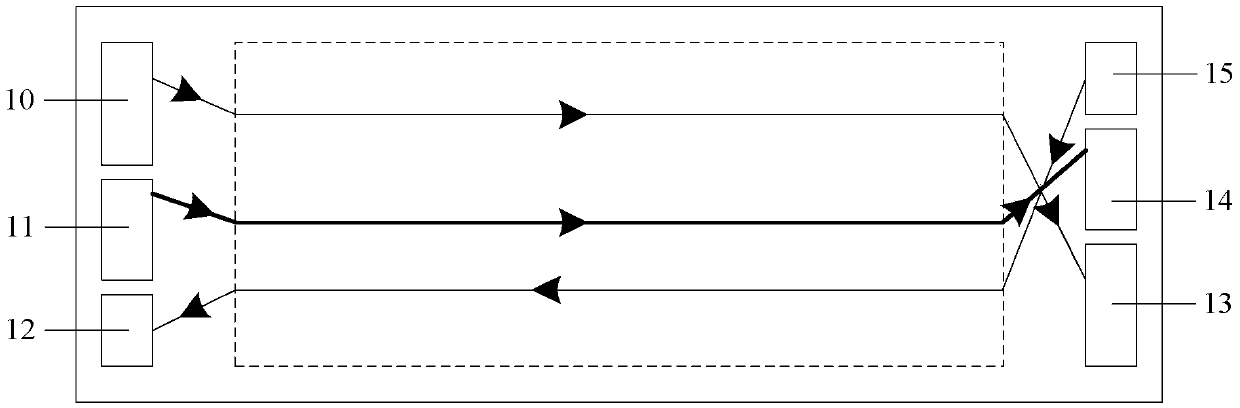

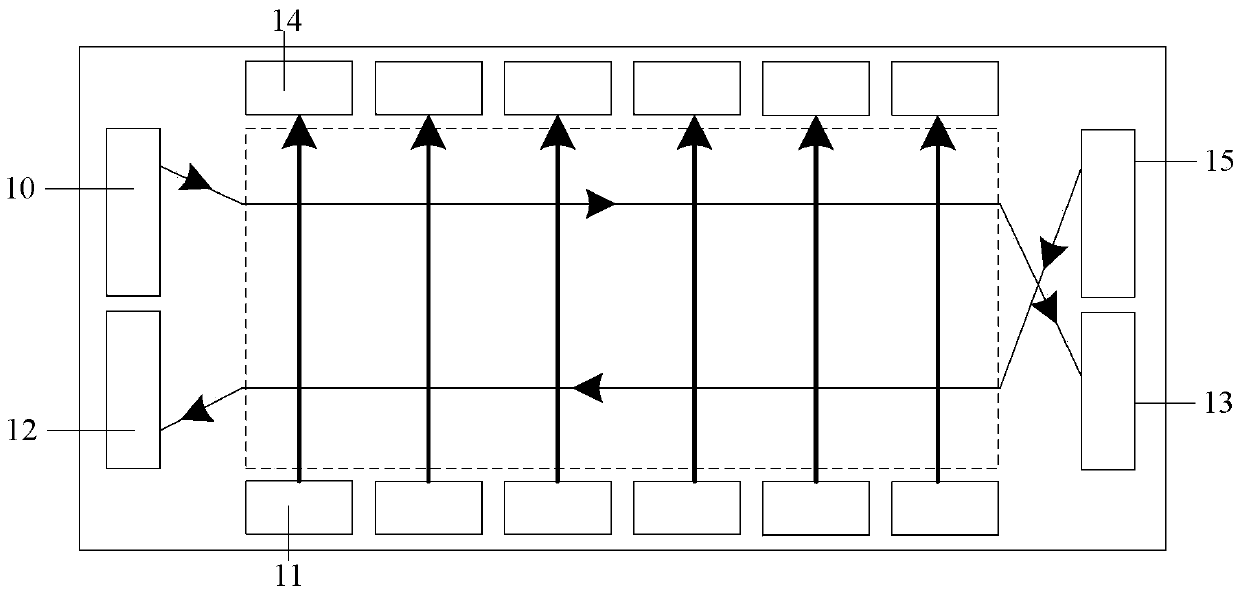

[0042] The inventor has found that although the inlet and outlet of the cooling liquid can be arranged on the long side of the bipolar plate, such as figure 2As shown, the cooling liquid inlet 11 is located at one long side of the bipolar plate, and the cooling liquid outlet 14 is located at the other long side of the bipolar plate, but, since the cooling liquid has no temperature gradient ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com