Synthesis method of cobalt-molybdenum bimetallic sulfide for supercapacitor electrode material

A technology for supercapacitors and electrode materials, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double-layer capacitors. It can solve unsatisfactory problems and achieve the effects of improving specific capacitance, good electrochemical performance, and high reversibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

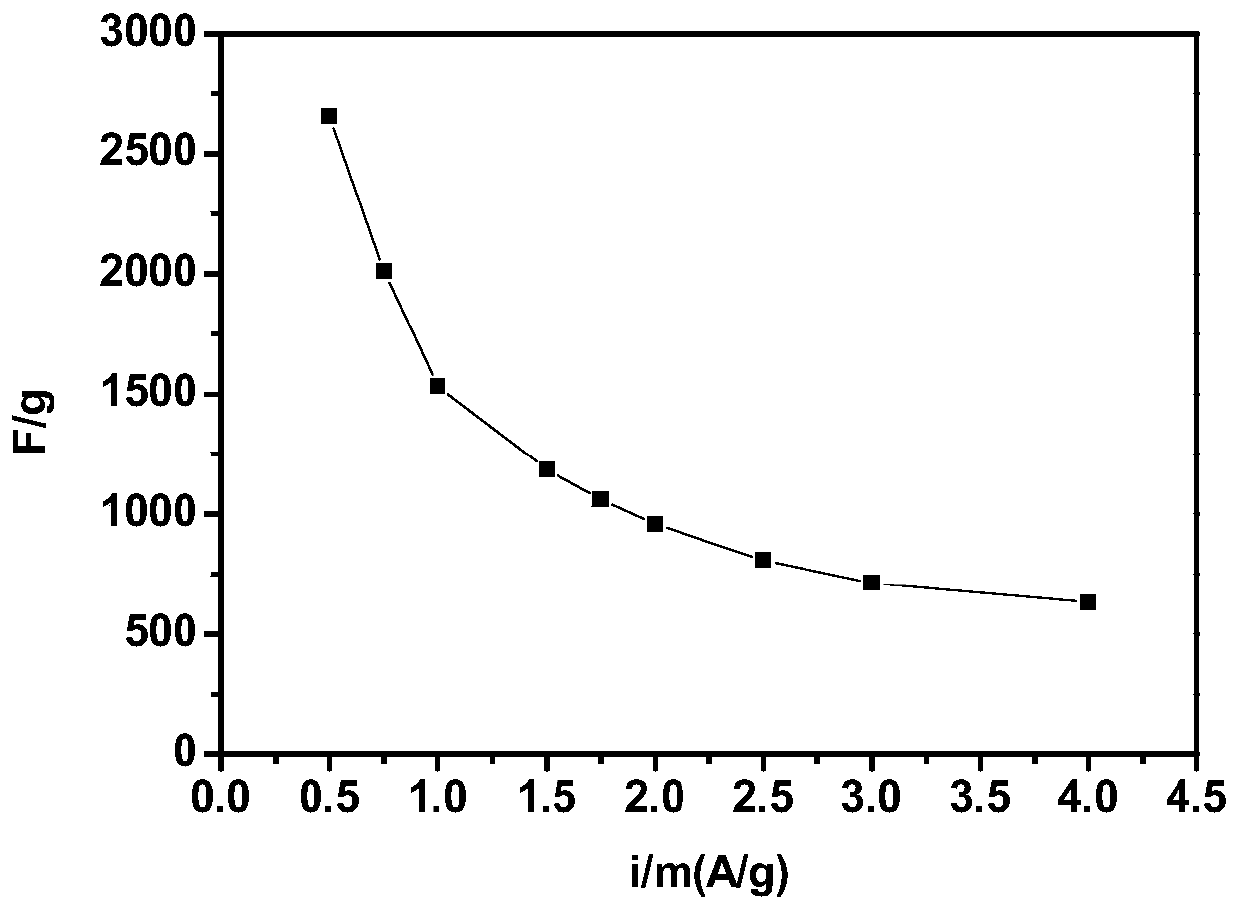

[0038] In the synthetic method of the cobalt-molybdenum bimetallic sulfide that is used for the supercapacitor electrode material of this example, at first, cobalt chloride hexahydrate (CoCl 2 ·6H 2 O) and deionized water are mixed and dissolved in a ratio of 0.002:1 to obtain solution A, and then the morphology regulator ammonium fluoride, sodium tetrathiomolybdate (Na 2 MoS 4 ) and deionized water were mixed and dissolved according to the mass ratio of 0.001:0.002:1 to obtain solution B. Then, mix solution A and solution B in equal volumes and carry out hydrothermal reaction. The reaction temperature is 100°C and the reaction time is 6 hours. Under the conditions of 0.8KPa and 60°C, vacuum drying was carried out for 10 hours to obtain cobalt-molybdenum bimetallic sulfides.

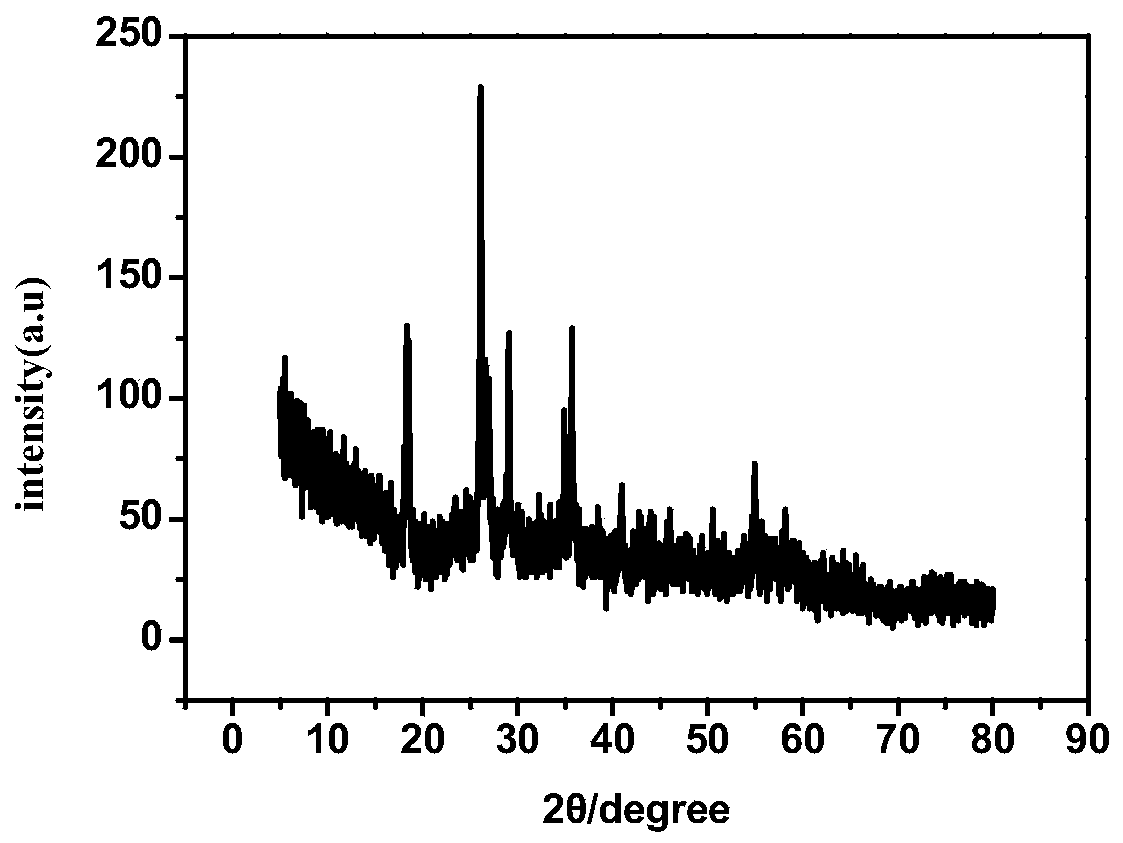

[0039] The cobalt-molybdenum bimetallic sulfide synthesized by this preparation example, after testing its XRD pattern is as follows figure 1Shown in (test conditions are Bruker D8 and BDX3300 X-ray ...

preparation example 2

[0044] In the synthetic method of the cobalt-molybdenum bimetallic sulfide that is used for supercapacitor electrode material of this example, at first, cobalt nitrate (Co(NO 3 ) 2 ) and deionized water are mixed and dissolved at a ratio of 0.003:1 to obtain solution A, and then the morphology regulator sodium lauryl sulfate, potassium tetrathiomolybdate (K 2 MoS 4 ) and deionized water were mixed and dissolved according to the mass ratio of 0.001:0.003:1 to obtain solution B. Then, mix solution A and solution B in equal volumes and carry out hydrothermal reaction. The reaction temperature is 120°C and the reaction time is 8 hours. Under the conditions of 0.8KPa and 60°C, vacuum drying was carried out for 10 hours to obtain cobalt-molybdenum bimetallic sulfides.

[0045] The electrode material of the cobalt-molybdenum bimetallic sulfide synthesized in this example was subjected to the same electrochemical test as in Example 1. After testing, its specific capacitance value r...

preparation example 3

[0047] In the synthetic method of the cobalt-molybdenum bimetallic sulfide that is used for the supercapacitor electrode material of this example, at first, cobalt bromide (CoBr 2 ) and deionized water are mixed and dissolved at a ratio of 0.003:1 to obtain solution A, and then the morphology regulator hexadecyltrimethylammonium bromide, ammonium tetrathiomolybdate ((NH 4 ) 2 MoS 4 ) and deionized water were mixed and dissolved according to the mass ratio of 0.002:0.004:1 to obtain solution B. Then, mix solution A and solution B in equal volumes and carry out hydrothermal reaction. The reaction temperature is 140°C and the reaction time is 10 hours. Under the conditions of 0.8KPa and 60°C, vacuum drying was carried out for 10 hours to obtain cobalt-molybdenum bimetallic sulfides.

[0048] The same electrochemical test as in Example 1 was performed on the cobalt-molybdenum bimetallic sulfide electrode material synthesized in this example. After testing, its specific capacita...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific capacitance value | aaaaa | aaaaa |

| Specific capacitance value | aaaaa | aaaaa |

| Specific capacitance value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com