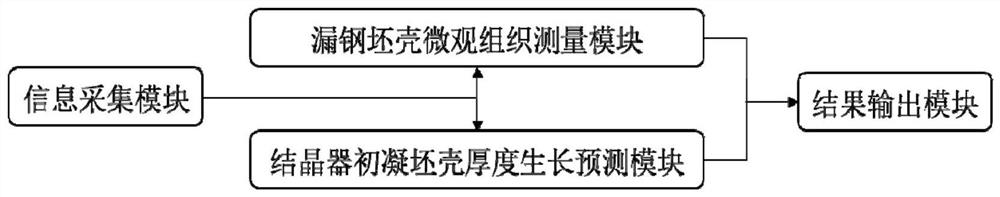

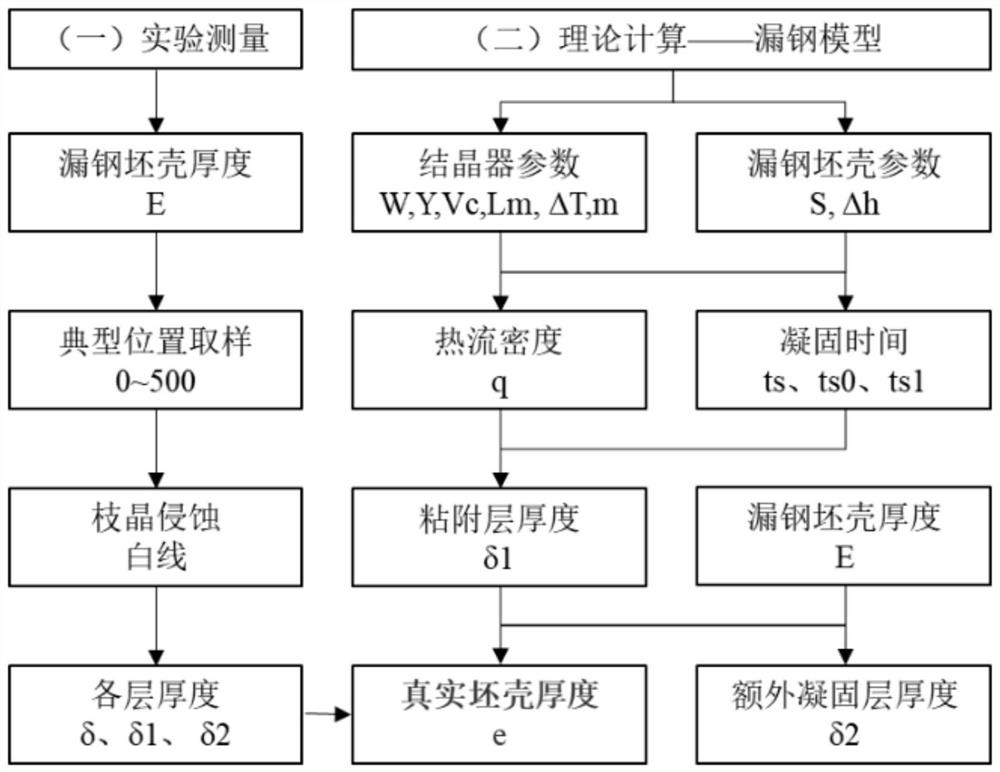

A system and method for measuring and predicting true primary shell thickness in a mold

A crystallizer and billet shell technology, which is applied in the field of measuring and predicting the thickness of the real primary solidified billet shell in the crystallizer, can solve the problems of the reduction of the use value of the breakout billet shell, and achieve the effect of solving the problem of estimation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

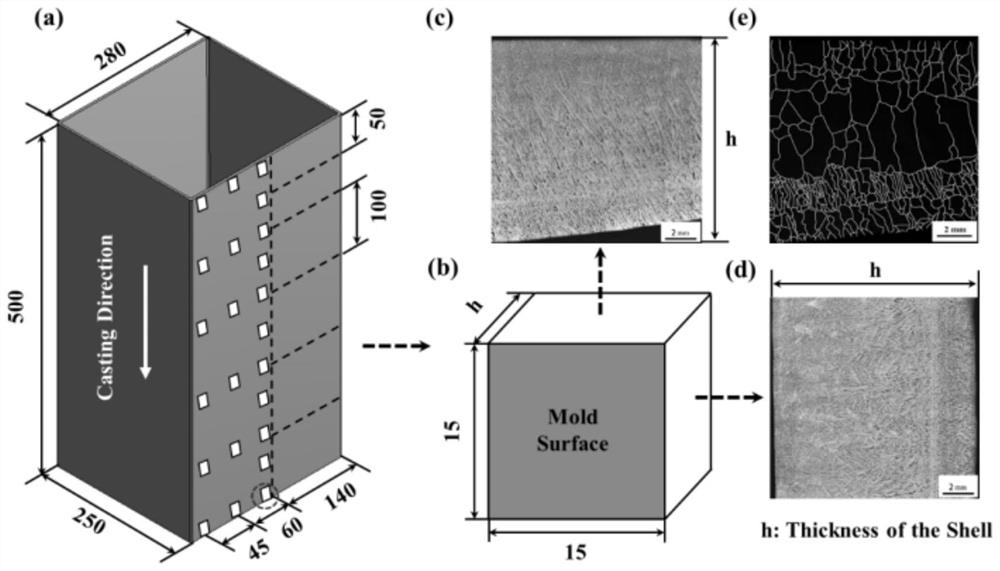

[0079] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention. On the contrary, the present invention covers any alternatives, modifications, equivalents and arrangements within the spirit and scope of the present invention as defined by the appended claims. Further, in order to give the public a better understanding of the present invention, some specific details are described in detail in the following detailed description of the present invention. The present invention can be fully understood by those skilled in the art without the description of these detailed parts.

[0080] The present invention will be further described below with reference to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com