Jet flow division valve control method and flow division valve control double-jet-pipe electro-hydraulic servo valve

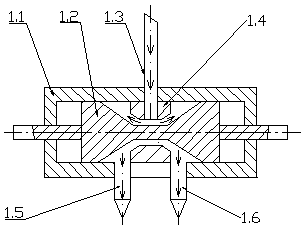

A diverter valve and dual jet technology, applied in servo motor components, valve details, multi-port valves, etc., can solve the problems of difficult welding of feedback rod components, easy to be affected by environmental vibration, and long rigidity of the jet pressure pipe. It is not easy to be affected by environmental vibration, the processing difficulty is not high, and the dynamic response is fast.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

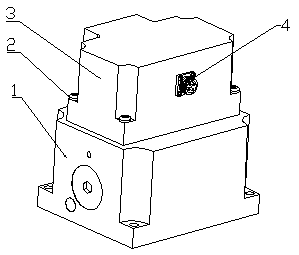

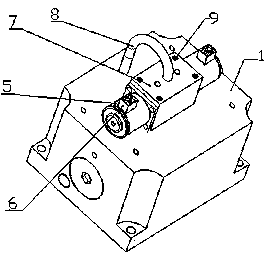

[0036] Embodiment: the main valve body 1 and the valve housing 23 in the present invention are made of high-quality steel 30#; the main valve core 16, the double cone valve core 26, and the splitter ring 25 are all made of 40Cr; the valve sleeve valve cover 3 and the end cover 12 , and the retaining ring 14 are made of carbon steel ZG25; the valve sleeve 15 is made of polytetrafluoroethylene; the model of the proportional electromagnet 5 is GP516-S-A; the seal material is made of NBR NBR; the return spring 13 is made of 70 steel. The processing of the main valve body 1 and the valve housing 23 is mainly completed on a CNC milling machine; the main valve core 16, the double cone valve core 26, and the splitter ring 25 are mainly completed by a CNC lathe.

[0037] When the control valve 7 is installed, first align the upper split ring 255 and the lower split ring 256 on the double cone valve core axis 262, and then use the screws 254 to fix the upper split ring 255 and the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com