Narrow-hardenability industrial gear steel and production method thereof

A production method and hardenability technology, applied in the direction of manufacturing converters, etc., can solve the problems of the large bandwidth of the gear steel, the gear steel does not meet the requirements of users, and achieve the effect of improving the strength and reducing the toughness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

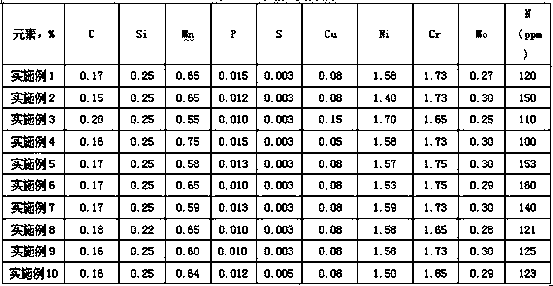

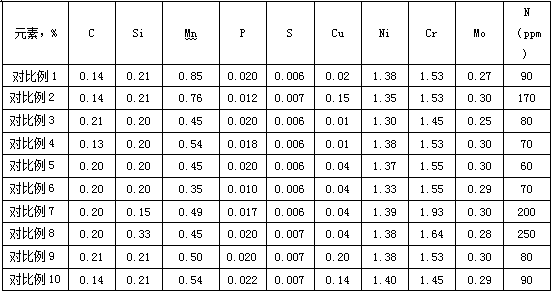

[0027] A narrow hardenability industrial gear steel, the mass percentage of each chemical composition of the steel plate is as follows: C: 0.15%-0.19%; Si: 0.22%-0.30%; Mn: 0.55%-0.75%; Cr: 1.65%-1.85 %; Mo: 0.25%-0.35%; Ni: 1.40-1.70%; S≤0.005%; P≤0.015%; Cu: 0.05%-0.15; N: 100-160PPM, the balance being Fe and unavoidable impurities.

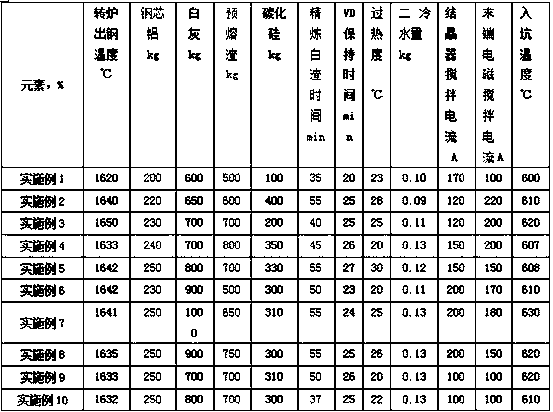

[0028] A production method of narrow hardenability industrial gear steel, including smelting and continuous casting steps, converter tapping conditions C≥0.06%, P≤0.010%, tapping temperature 1620-1650℃;

[0029] Add 200-300kg of core aluminum during the tapping process, add alloy, 600-1000kg white ash, 500-800kg pre-melting slag after adding aluminum; 120-180m aluminum wire after tapping the furnace;

[0030] Refining silicon carbide powder 100~400kg and 30-60kg aluminum particles are used for diffusion deoxidation, maintaining the reducing atmosphere in the furnace, white slag retention time ≥ 35 minutes; VD high vacuum (below 67Pa) retention time ≥ ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com