Method for preparing glutamic acid fermentation medium

A fermentation medium and glutamic acid technology, applied in the field of glutamic acid fermentation medium preparation, can solve the problems of unstable fermentation, separation and extraction, low nutritional value of hydrolysate, difficult control of fermentation process, etc. Conducive to microbial utilization, acid production, and stability of enzymatic hydrolysis products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The enzymatic hydrolysis process of amino acid fermentation cells comprises the following steps:

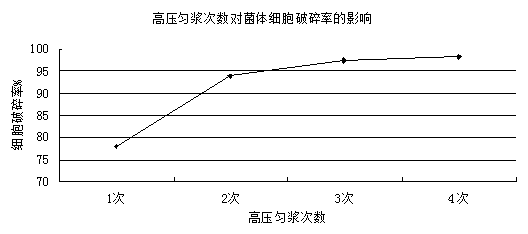

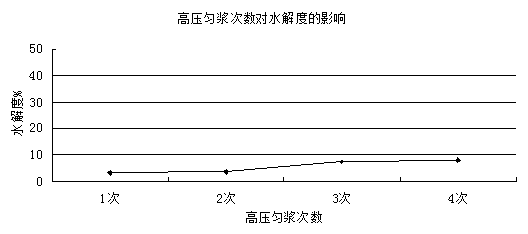

[0034] The amino acid fermentation broth is separated by a disc separator with a rotation speed of 5000rpm and a centrifugation time of 3min to collect the bacterial precipitate; add a concentration of 5g / L potassium dihydrogen phosphate aqueous solution to the bacterial precipitate and configure it to a concentration of 200g / L For the bacterial cell suspension of L, use a high-pressure homogenizer to homogenize the bacterial cell suspension, the homogenization pressure is 90Mpa, the temperature is 25°C, homogenize 3 times; stop the homogenization treatment, centrifuge at 1000rpm for 5min, and collect The upper layer of liquid and sediment (cell wall fragments and macromolecular proteins), then add 10 times the weight of purified water to the sediment, stir evenly, and use 20kHz ultrasonic waves for 20 minutes, then adjust the temperature to 45 ° C, using Neutral protease ...

Embodiment 2

[0036] The enzymatic hydrolysis process of amino acid fermentation cells comprises the following steps:

[0037]The amino acid fermentation broth is separated by a disk separator with a rotation speed of 4000rpm and a centrifugation time of 3min to collect the bacterial precipitate; add a concentration of 7g / L potassium dihydrogen phosphate aqueous solution to the bacterial precipitate, and configure it to a concentration of 250g / L For the bacterial cell suspension of L, use a high-pressure homogenizer to homogenize the bacterial cell suspension. The homogenization pressure is 90Mpa, the temperature is 25°C, and the homogenization is performed 3 times; stop the homogenization treatment, centrifuge at 1000rpm for 4min, and collect The upper liquid and sediment (cell wall fragments and macromolecular protein), then add 8 times the weight of purified water, stir evenly, use 20kHz ultrasonic wave for 30min, then adjust the temperature to 45°C, and use neutral protease to hydrolyze ...

Embodiment 3

[0039] The enzymatic hydrolysis process of amino acid fermentation cells comprises the following steps:

[0040] The amino acid fermentation broth is separated by a disc separator with a rotation speed of 5000rpm and a centrifugation time of 3min to collect the bacterial precipitate; add a concentration of 10g / L potassium dihydrogen phosphate aqueous solution to the bacterial precipitate, and configure it to a concentration of 220g / L For the bacterial cell suspension of L, use a high-pressure homogenizer to homogenize the bacterial cell suspension, the homogenization pressure is 90Mpa, the temperature is 25°C, homogenize 3 times; stop the homogenization treatment, centrifuge at 1000rpm for 5min, and collect The upper liquid and sediment (cell wall fragments and macromolecular protein), then add 9 times the weight of purified water to the sediment, stir evenly, use 20kHz ultrasonic wave for 20min, and then adjust the temperature to 45 ℃, using Neutral protease hydrolysis, the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com