Nano metal-stearate composite material and its preparation method and application

A stearate and nano-metal technology, applied in the field of nano-materials, can solve the problems of affecting the mechanical properties of materials, uneven dispersion, large agglomeration of powders, etc., and achieve good antibacterial and disinfection effects of nano-metals.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] A kind of preparation method of nano metal-stearate composite material of the present invention, comprises the following steps:

[0045] Dissolve stearate in heated low-carbon alcohol, and mix with nano metal particles;

[0046] Cool down to precipitate the nanometer metal-stearate complex.

[0047] Through the above preparation method, utilizing the feature that the solubility of stearate in low-carbon alcohol changes greatly with temperature, stearate and nano-metal particles are dissolved in low-carbon alcohol in steps under heating conditions, and hardened in the solution. The stearate is adsorbed on the surface of the nano-metal particles, and during the cooling process, as the solubility of the stearate decreases, the stearate and the nano-metal particles co-precipitate to form a composite nanomaterial. Compared with simply mixing stearate powder and nano-metal particles, when applied to the preparation of functional fibers, plastics, rubber materials or coatings...

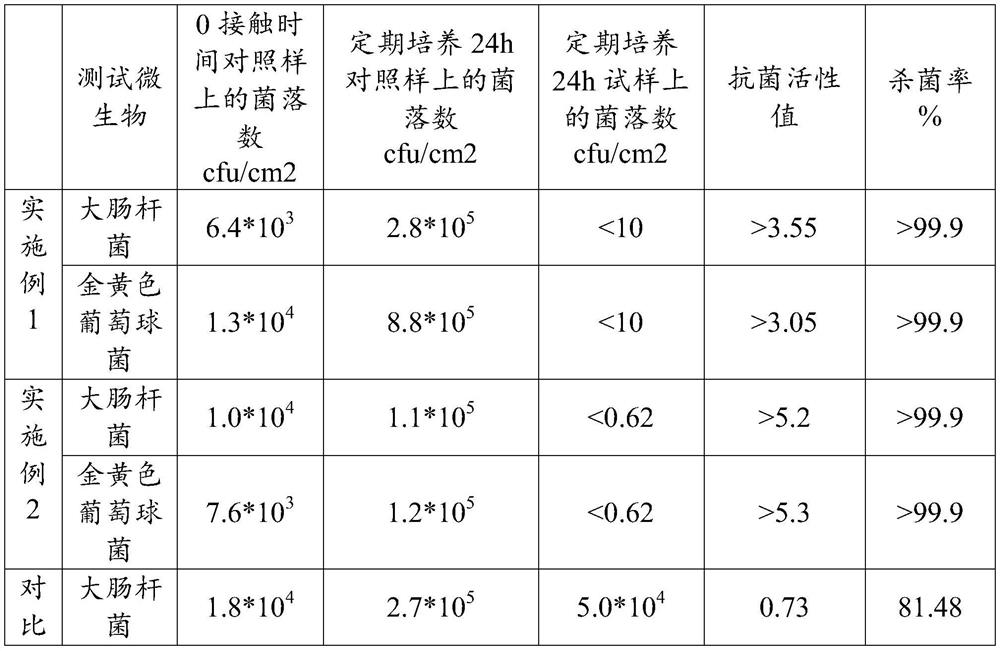

Embodiment 1

[0060] Example 1 Preparation of 20wt% nanometer silver-calcium stearate composite powder

[0061] The preparation method of the 20wt% silver-calcium stearate nanocomposite powder of the present embodiment is as follows

[0062] 1) Add 1000ml of absolute ethanol into a three-necked flask (with condensing reflux device), heat in a water bath until boiling, and condense and reflux for 60 minutes;

[0063] 2) Add 80 grams of calcium stearate into absolute ethanol (about 80°C) heated to boiling in a water bath, continue heating and stirring to dissolve, and obtain calcium stearate ethanol solution;

[0064] 3) Measure 1000ml of nano-silver (particle size around 25nm) nano-silver sol with a concentration of 20000ppm, slowly add it to calcium stearate ethanol solution, and continue to stir for 15min;

[0065] 4) The three-necked flask is placed in ice water for rapid cooling to obtain 20wt% nanometer silver-calcium stearate composite powder precipitation;

[0066] 5) vacuum filtrat...

Embodiment 2

[0068] Example 2 Preparation of 10wt% nanometer copper-barium stearate composite powder

[0069] 1) Add 1000ml of isopropanol into a three-neck flask (with condensing reflux device), heat in a water bath until boiling, and condense and reflux for 90 minutes;

[0070] 2) Add 90 grams of barium stearate to the isopropanol solution (about 80°C) heated to boiling in a water bath, continue heating and stirring to dissolve, and obtain calcium stearate isopropanol solution;

[0071] 3) Measure 500ml of nano-copper (particle size is about 50nm) nano-copper sol with a concentration of 20000ppm, slowly add it to the barium stearate isopropanol solution, and continue to stir for 20 minutes;

[0072] 4) cooling the three-necked flask in cold water to obtain nano copper-barium stearate composite powder precipitation;

[0073] 5) vacuum filtration;

[0074] 6) Drying in an oven at 50° C. for 8 hours to obtain a nano-copper-barium stearate composite powder, wherein the nano-copper content ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com